Transparent epoxy - DoPox® AquaCoat 30-11 Transparent

DoPox® AquaCoat 30-11 Transparent is a two-component (2K), highly vapor-permeable, transparent epoxy for protecting floors and walls.

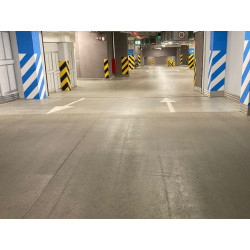

It forms a transparent*, satin coating on the substrate, which effectively reduces concrete dusting and protects against dirt and other surface contaminants. It is suitable for foot traffic, cars, and forklifts (depending on the system).

AquaCoat 30-11 Transparent epoxy allows the substrate to breathe and allows water vapor to pass through, thus preventing delamination of the coating and the formation of blisters. This means it can be applied to old/seasoned as well as fresh and/or damp concrete (7 days old) and cement substrates.

The epoxy is water-soluble and contains no Volatile Organic Compounds (VOC = 0 g/l) or solvents. This makes it safe for people and the environment. It does not emit any unpleasant odors during application.

Thanks to its properties, AquaCoat 30-11 transparent epoxy is an excellent solution for protecting floors in basements, garages, parking lots, industrial facilities, agriculture, etc.

Consumption: 0.2 kg/m² per coat

More information about AquaCoat 30-11 Transparent epoxy.

* Note on transparency

AquaCoat 30-11 Transparent two-component epoxy creates a transparent coating, but it is not completely colorless. When applied in thicker coats, it may leave a slightly milky finish on the substrate. In addition, like other epoxy resins, the product has incomplete UV resistance and may yellow over time. If you are looking for a completely colorless, non-yellowing varnish, we recommend using Hydrograff HP polyurethane varnish.

Instructional videos:

The video below shows the application of AquaCoat 30-11 in color—the application process is identical to that of the colorless AquaCoat 30-11 Transparent. We invite you to watch it.

Industrial flooring - quick and easy to apply resin

The microporous coatings formed during the curing process breathe and allow water vapor to pass through, enabling application on substrates with increased humidity.

The varnish is water-based, contains no VOCs (0 g/l) or solvents, and does not emit unpleasant odors during application.

Key properties:

Product characteristics

- water-based, two-component (2K) epoxy.

Resistance and vapor permeability

- protects the substrate against dust, dirt

, and other surface contaminants, - resistant to medium-intensity car and

forklift traffic (in the appropriate system), - has breathable and water vapor permeable properties,

can be applied to substrates with increased humidity, - creates microporous coating systems during the curing process,

which prevents blistering and delamination of the coating, - temperature resistance (Tg - glass transition temperature): 80°C.

Aesthetics

- creates a transparent coating* with a satin finish.

Application and safety

- water-soluble,

has a faint odor during application, - safe for people and the environment,

does not contain VOCs (0 g/l) or solvents, - can be applied to fresh, damp, several-day-old concrete and

cement substrates (7 days), - suitable for both floors and walls,

- for best results,

we suggest using a nylon roller for epoxy paints - 14 mm.

Anti-slip properties

- system: AquaCoat 30-11 + NS 200 anti-slip additive has been tested for slip resistance in accordance with PN-EN 13036-4 (check the certificate):

- PTV in dry conditions: 72,

- PTV in wet conditions: 64,

- R: R12.

Transparent epoxy with high vapor permeability:

Thanks to its very high vapor permeability, work can begin as soon as the concrete is hard enough to be properly prepared for the application of AquaCoat 30-11 Transparent, i.e., sanded, shot blasted, etc. As a rule, however, for safety reasons, we recommend waiting 7 days after pouring the concrete before applying the system.

If you need to apply the system sooner, please contact us.

Vapor-permeable systems:

| System name: | System per m2: | Cost per m2: |

|---|---|---|

|

Dust-reducing system:

|

1 x 0.15 kg AquaCoat 30-11 Transparent | check the cost of the system |

|

Light-duty systems:

|

1 x 0.15 kg AquaCoat 30-11 Transparent + 1 x 0.2 kg AquaCoat 30-11 Transparent |

check the cost of the system |

|

Systems for medium loads:

|

1 x 0.15 kg AquaCoat 30-11 Transparent + 2 x 0.2 kg AquaCoat 30-11 Transparent |

check the cost of the system |

Note: The above systems are general recommendations. Each project should be treated individually. If you have any doubts, please contact us so that we can select the right system for your specific floor/wall.

Epoxy tested in accordance with PN-EN 13036-4:

The AquaCoat 30-11 anti-slip system for medium loads achieved a pendulum test value (PTV) of 72 in dry conditions and 64 in wet conditions in independent tests. Guidelines in the UK recommend a PTV value of 36 in dry conditions and in wet and contaminated conditions.

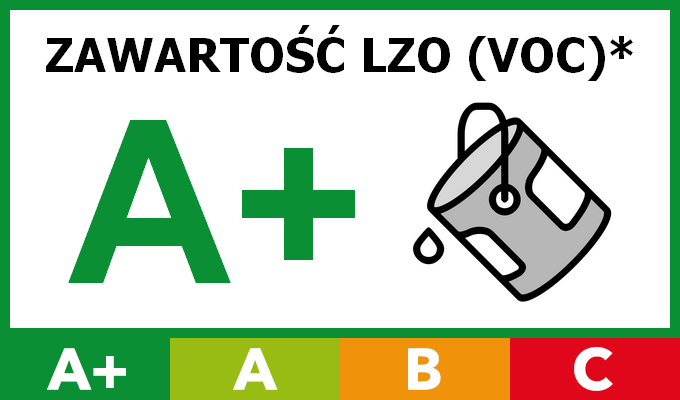

Volatile Organic Compounds:

AquaCoat 30-11 Transparent epoxy

Volatile Organic Compounds (VOC) content - 0 g/l

* Information on the level of vapor emissions (VOC) during application and until the paint is fully cured.

Emission levels from A+ (very low) to C (high).

Additional information on Volatile Organic Compounds.