RD-Roof White reflective paint

RD-Roof White paint is a white, single-component heat-reflective coating. It can be used on various types of flat or sloped roofs. It helps cool industrial, commercial, and private buildings. It can also be successfully used as a reflective layer under photovoltaic panels.

- SRI = 105 - Thanks to its high solar reflectance index (SRI), special pigmentation, and very high UV resistance, RD-Roof White paint allows for maximum solar reflection over a long period of time.

- SR = 83% - The high solar reflectance (SR) means that RD-Roof White paint reflects as much as 83% of solar radiation. It effectively reduces the heating of building interiors.

RD-Roof White paint is water-based, easy to use, and does not pose a fire hazard. It is a quick-drying coating system that significantly reduces downtime during installation and increases productivity on site. Virtually odorless, it does not affect people in painted rooms and can therefore be used in occupied buildings.

UV-reflective roofs significantly reduce the surface temperature of the roof and limit heat transfer into the building. This can lower the temperature inside the building by several degrees and reduce the use of air conditioning systems.

In addition, by maintaining a lower surface temperature, RD-Roof White increases the efficiency of photovoltaic panels (especially double-sided panels).

A double benefit: cooler rooms and more energy generated.

SR and SRI coefficients for RD-Roof White

- SRI = 105

- SR = 83%

The terms "solar reflectance index" (SRI) and "solar reflectance" (SR) refer to the interaction of surfaces with solar energy, but measure different aspects:

-

Solar Reflectance Index - SR

- Reflectance is a measure of the proportion of solar radiation (energy from the sun) that is reflected by a surface rather than absorbed. It is usually expressed as a percentage and indicates how much solar energy is reflected by the surface.

- Reflectance is often used when discussing the properties of roofing materials, coatings, and other surface finishes, indicating how much sunlight they can reflect.

-

Solar Reflectance Index - SRI

- SRI is a more comprehensive measure that takes into account not only reflectance but also the emissivity of the material. Emissivity is the ability of a material to release absorbed heat.

- SRI is calculated based on solar reflectance and thermal emissivity values to determine how hot a surface will become when exposed to sunlight compared to standard black (with a reflectance of 0 and an emissivity of 0.90) and standard white (with a reflectance of 1 and an emissivity of 0.90) under the same conditions.

- SRI values typically range from 0 to 100, with higher values indicating materials that remain cooler in the sun by reflecting solar radiation and effectively emitting thermal radiation.

In summary, while reflectance is a simple measure of how much solar energy is reflected by a surface, SRI provides a more holistic view of how a surface will behave in terms of heat gain from solar exposure, combining reflectance and emissivity into a single index.

Key features:

Product characteristics

- single-component, water-based, white paint,

based on new-generation resins, - reflects up to 83% of heat from solar radiation, SRI coefficient +/-105,

allowing for a natural reduction in the temperature inside buildings.

Resistance

- has very high resistance to UV radiation,

- has waterproofing properties,

in combination with Elastometal/Elastodeck (as a primer - see systems), - protects the substrate from damage caused by temperature fluctuations,

- ensures long-term performance,

allows for maximum reflection of sunlight and heat over a long period of time. - RD-Roof White remains flexible at low and high temperatures

At low temperatures (-26°C), the product meets the requirements of ASTM D 1305. The coating's resistance to elevated temperatures has been successfully tested in internal tests at 80°C.

A sample coated with RD-Roof White was exposed to a temperature of 80°C for 8 hours and then cooled to room temperature for 16 hours. The cycle was repeated for a period of 14 days, with no signs of loss of adhesion, abrasion, or visual defects.

Safety

- Water-soluble, virtually odorless,

does not affect people in painted rooms, - safe for applicators and the environment, contains

no harmful substances and poses no fire hazard.

Application

- suitable for bituminous and metal roofs,

with the appropriate primer - see systems, - can be used under solar panels,

maintaining a lower substrate temperature increases the efficiency of photovoltaic panels, - easy to

apply with a brush, roller, or airless spray,

Systems:

The table below shows which system should be used depending on the substrate.

| Substrate | System type | System | Cost |

|---|---|---|---|

| Bituminous roofs older than one year | Thermal protection | 0.30 kg/m² Elastodeck + 0.25 kg/m² RD-Roof White |

from PLN 24.00 net per m2 |

| Sealing + thermal protection | 1.5 kg/m2 Elastodeck + 0.25 kg/m2 RD-Roof White |

from PLN 73.50 net per m2 | |

| Steel roofs | Thermal protection | 0.25 kg/m2 Elastometal + 0.25 kg/m2 RD-Roof White |

from PLN 23.00 net per m2 |

| Anti-corrosion + thermal protection | 0.6 kg/m2 Elastometal + 0.25 kg/m2 RD-Roof White |

from PLN 40.00 net per m2 | |

| Anti-corrosion + sealing + thermal protection | + 1.3 kg/m² Elastometal + 0.25 kg/m² RD-Roof White |

from PLN 73.50 net per m2 | |

| EPDM | Thermal protection | 0.30 kg/m2 Elastodeck (diluted with 5% water) + 0.3 kg/m2 RD-Roof White |

from PLN 25.50 net per m2 |

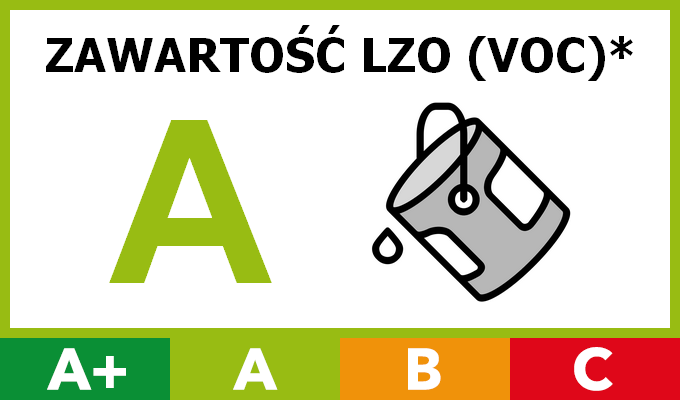

Volatile Organic Compounds:

RD-Roof White heat-reflective paint

Volatile Organic Compounds (VOC) content - max. 30 g/l

* Information on the level of vapor emissions (VOC) during application and until the paint is fully cured.

Emission levels from A+ (very low) to C (high).

Additional information on Volatile Organic Compounds.