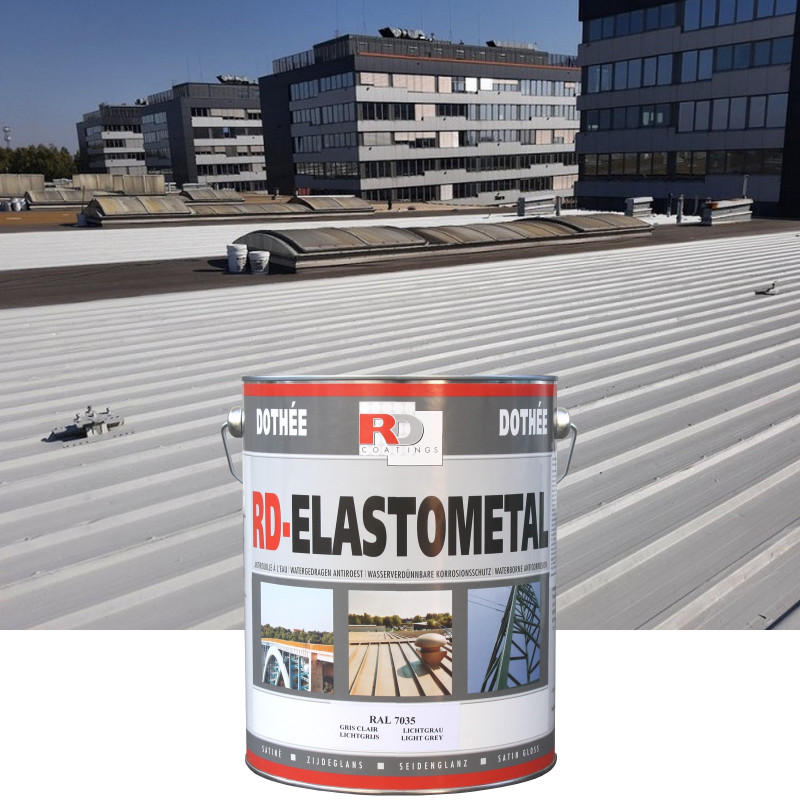

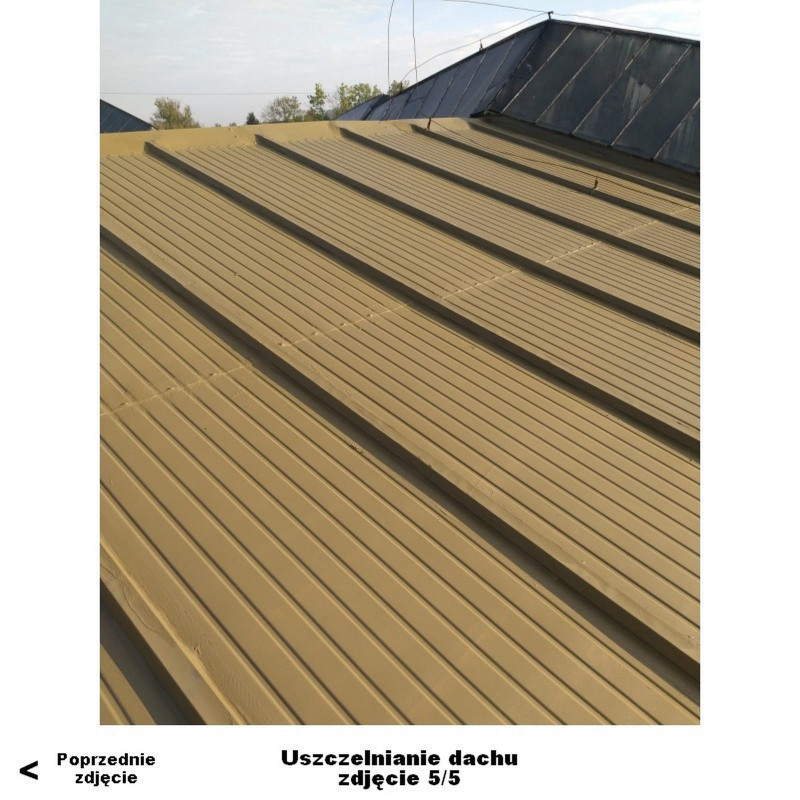

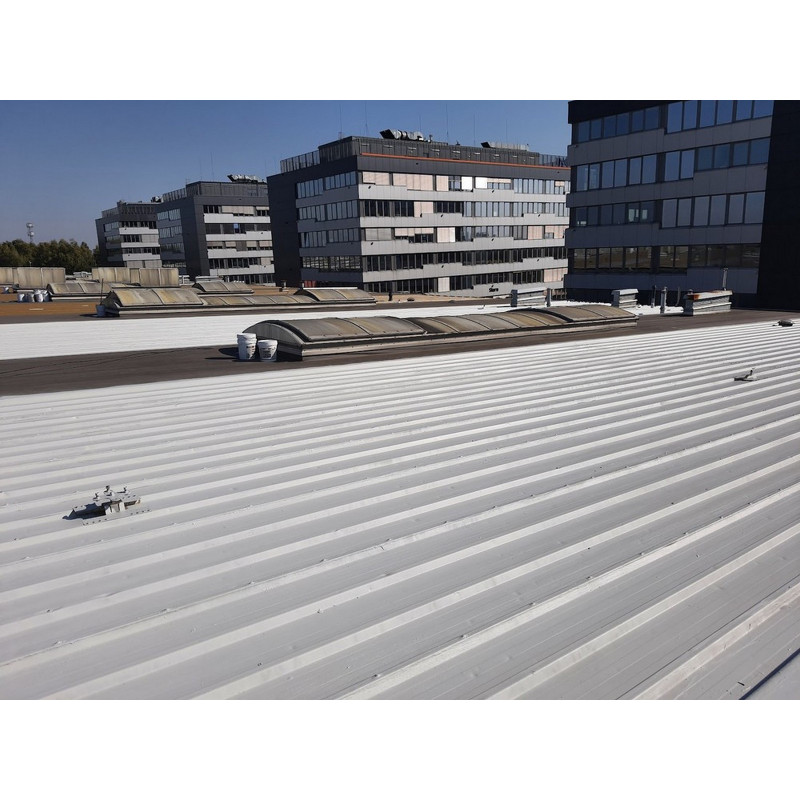

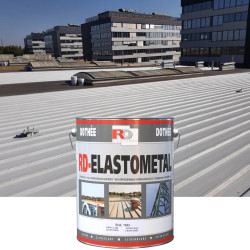

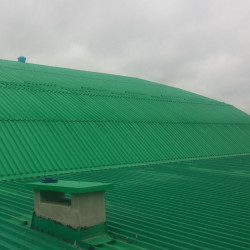

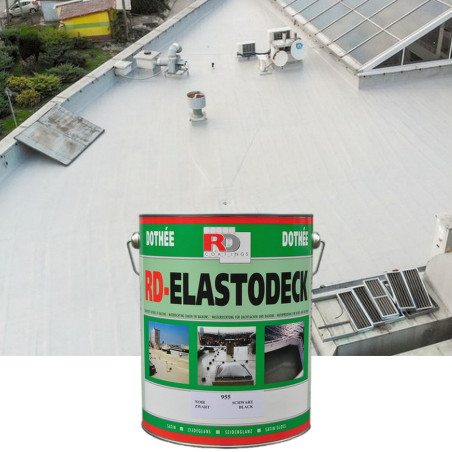

Sealing of metal roofs - Elastometal

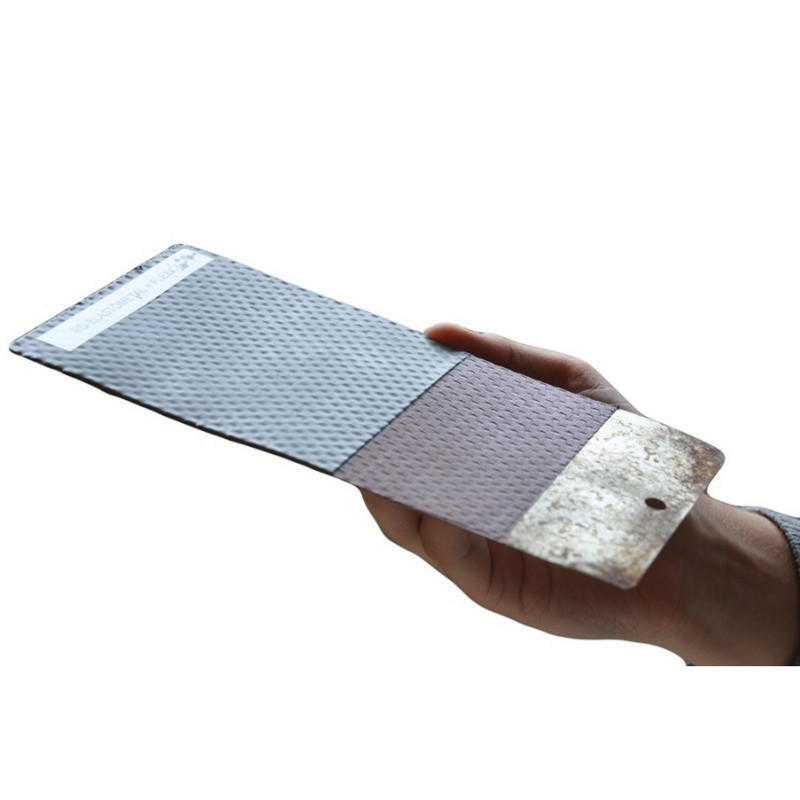

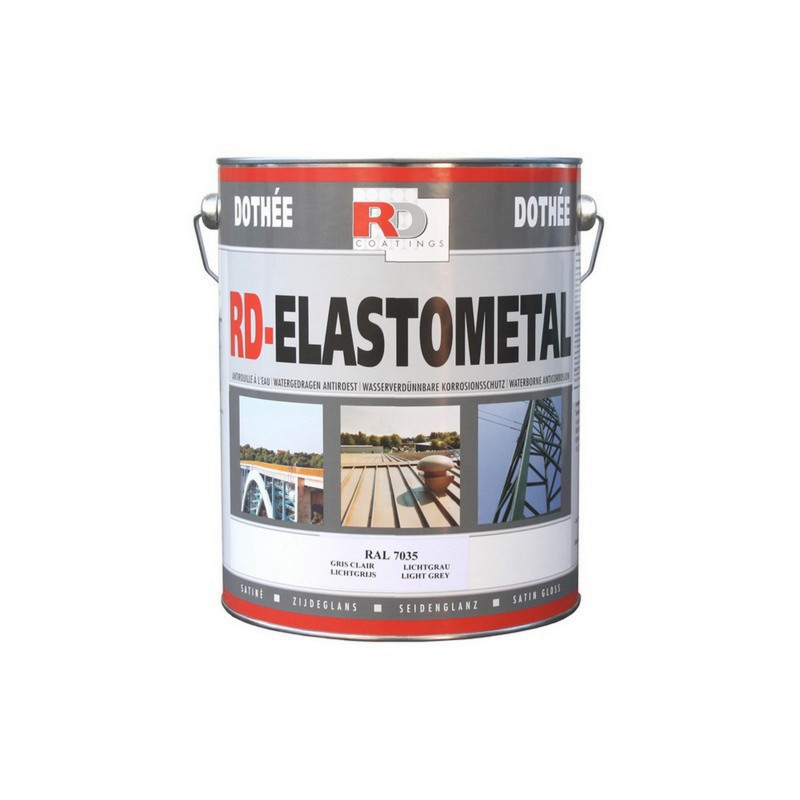

Elastometal is a single-component, highly durable anti-corrosion preparation based on styrene-acrylic copolymer and zinc phosphate. After application, it forms a waterproof, highly elastic (> 200%), thick (350 μm), durable (possibility of obtaining a 10-year manufacturer's warranty for corrosion protection and roof sealing *), seamless coating that perfectly protects surfaces, including metal roofs, against corrosion, water penetration, and snow.

Elastometal metal roof sealing - key properties:

- sealing properties

- permanent elasticity

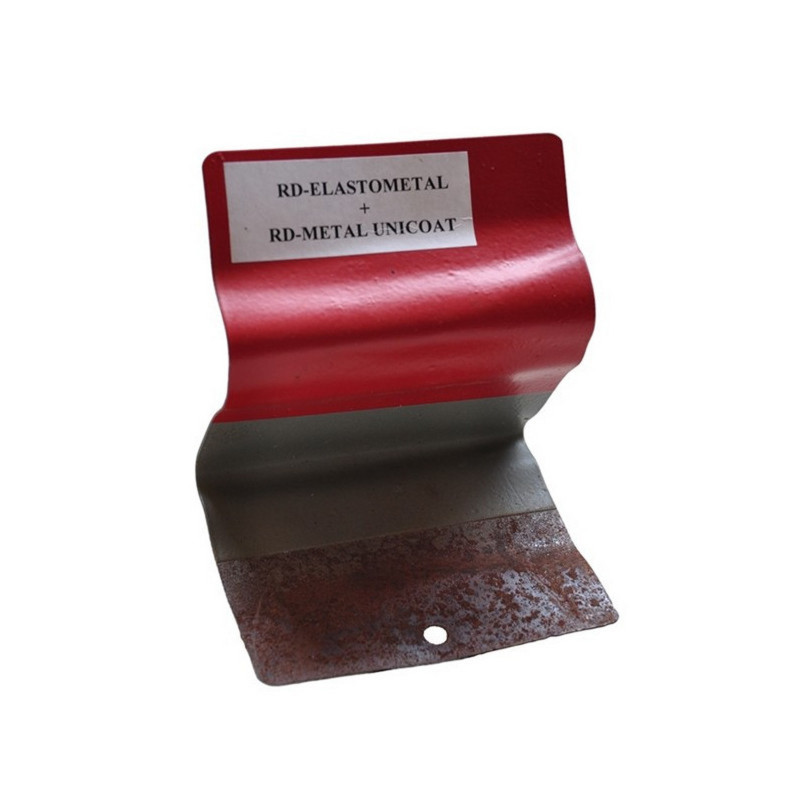

- excellent adhesion and high-quality anti-corrosion pigments

- long service life

- high resistance to weather conditions

- Health and environmentally friendly

- non-flammable, does not spread fire, both during and after application - ITB Classification Report - Broof(t1) - PN-EN 13501-5:2016 method 1

- suitable for use in the food industry (without direct contact with food) - PZH certificate

Yield: 250-400 g/m2

More information about sealing metal roofs with Elastometal.

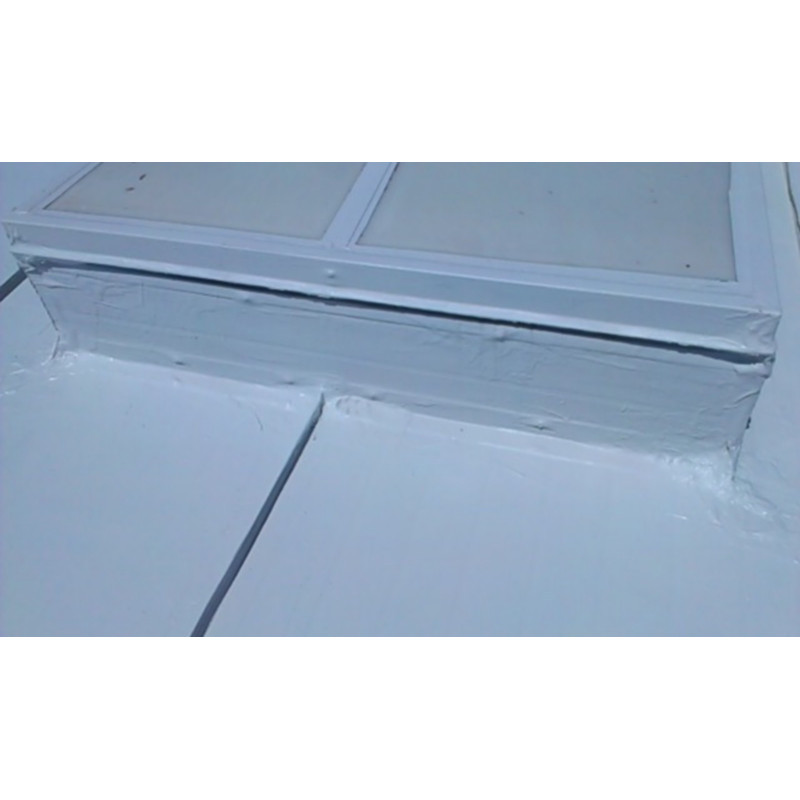

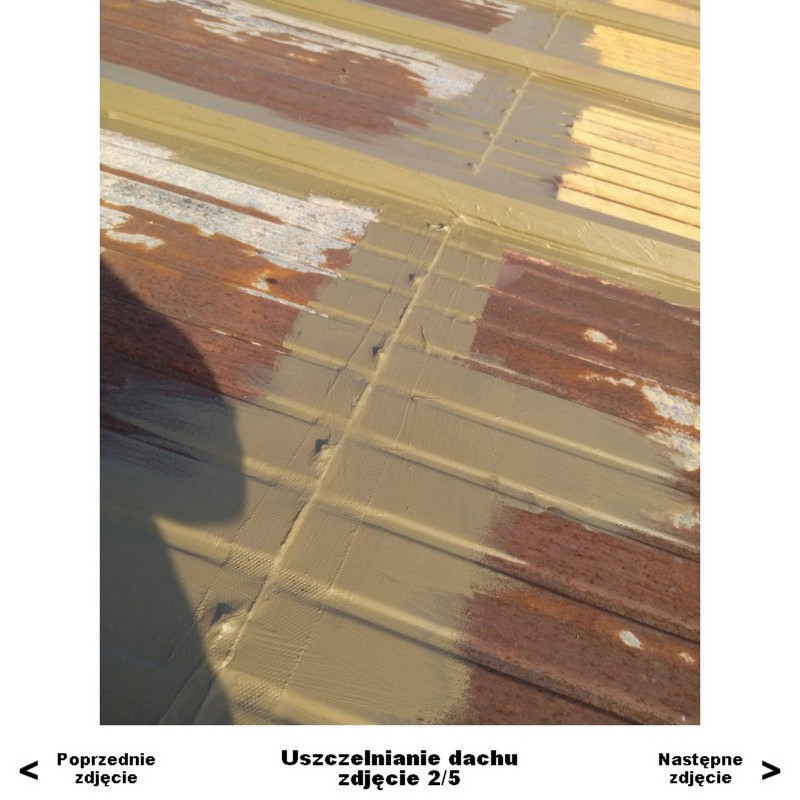

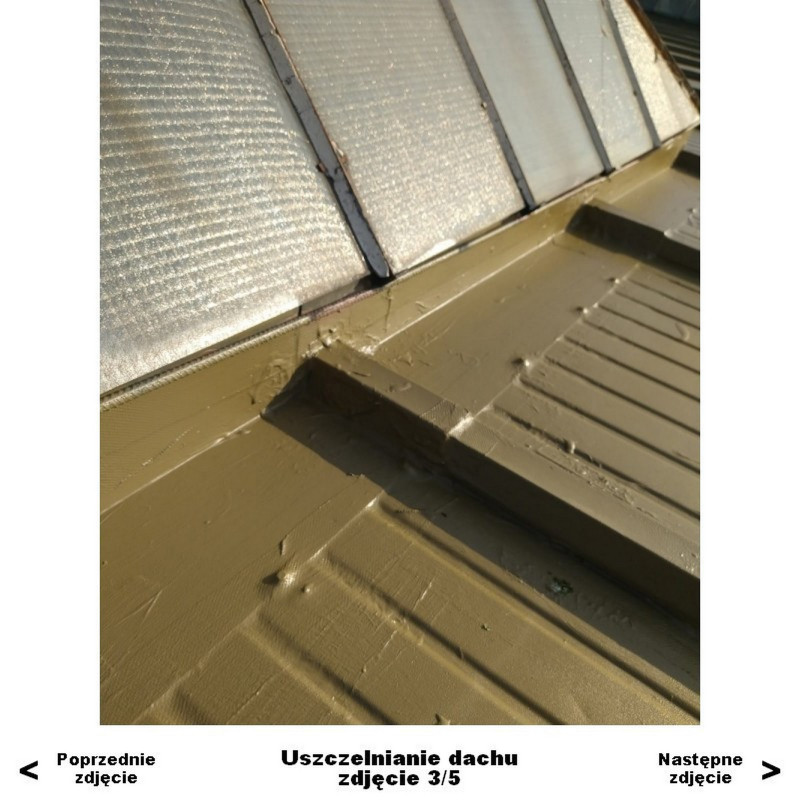

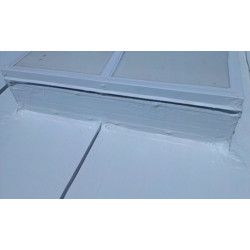

Waterproofing - Elastometal paint creates an impermeable coating against moisture and air. It stops the spread of rust. In addition, together with reinforcing fabric, it creates a waterproof membrane for metal roofs and platforms.

High elasticity - resistant to vibrations, deflections, and impacts. Does not crack or peel. Ideal for roofs where large metal surfaces shrink and expand due to thermal or elastic effects.

Protection for years - unique formula provides long-term corrosion protection (15-25 years) in aggressive industrial environments (C5 High). Salt spray test 1440h+.

Anti-corrosion protection in diverse environments - thanks to its properties, Elastometal is the ideal solution for anti-corrosion protection in diverse environments, including:

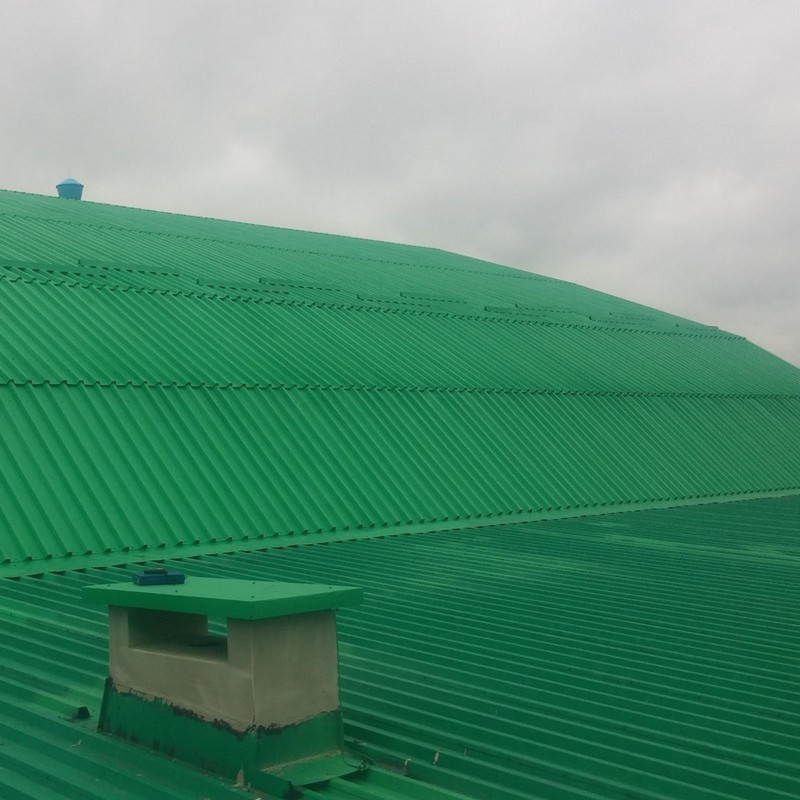

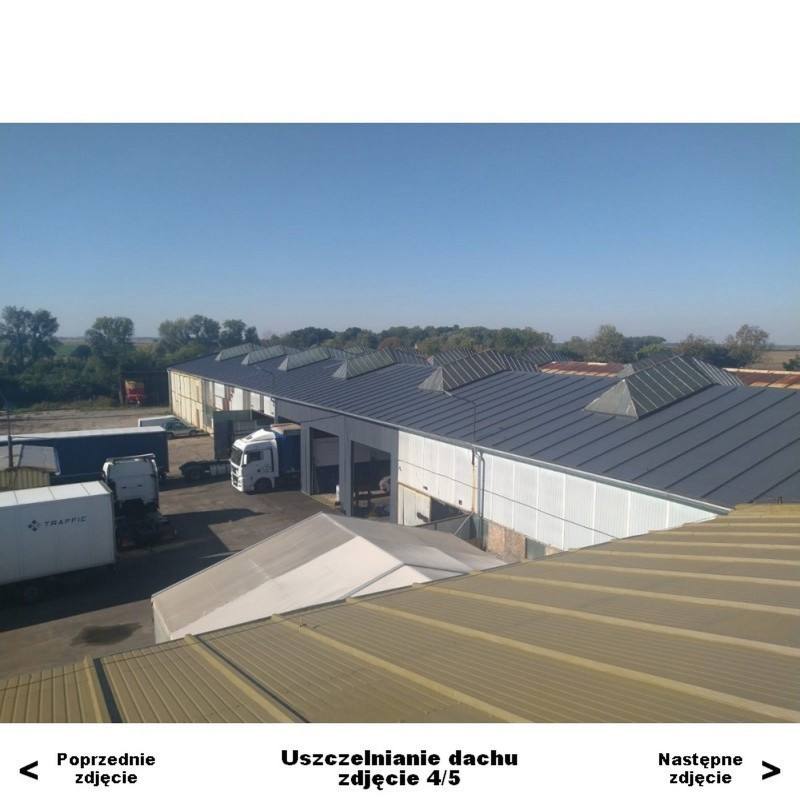

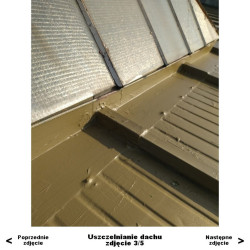

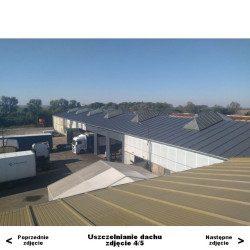

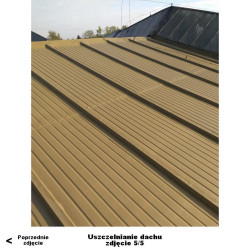

- renovation and sealing of metal roofs

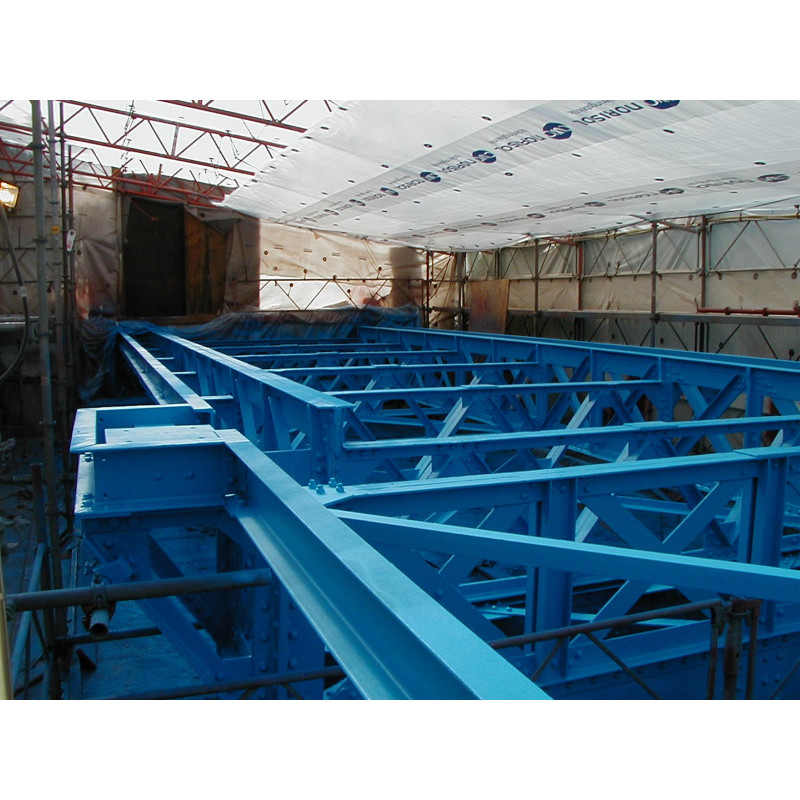

- bridges, marine structures, refineries, petrochemical and chemical plants

- external coating for tanks (water, oil, gas, grain, etc.)

- metal on buildings (roofs, sandwich panels, walls, lintels, flashings, etc.)

- steel structures (flyovers, pipelines, towers, supports, etc.)

- equipment (cranes, trucks, chassis, frames, etc.).

* A 10-year warranty for corrosion protection and roof sealing is issued by the paint manufacturer RD-Coatings and the company performing the painting work. In order to obtain the warranty, the work must be inspected by RD-Coatings. The work must be performed by an approved contractor in accordance with RD-Coatings' 10-year warranty procedures.

Instructional videos

Painting roofs – Paint for sheet metal roofs

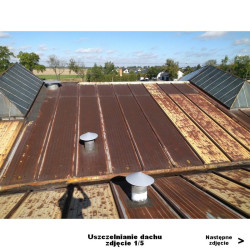

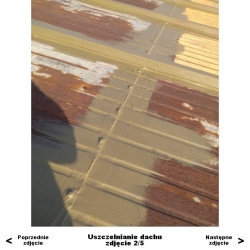

Sealing a metal roof made of sandwich panels

Sealing and painting a titanium zinc roof

Documentation:

Datasheets

- Technical Data Sheet – PL version / ENG – detailed product properties and application method

- Safety Data Sheet – PL version / ENG – chemical, safety and transport information

Application Instructions

- Application Instructions – practical step‑by‑step application guide

Declarations

- Declaration of Performance (DoP) – for the Elastometal + Monoguard system in C5 High environment

- Deklaracja parametrów użytkowych (wg ISO/ASTM) - for Elastometal

Certificates – Corrosion Protection Properties

- National Technical Assessment (KOT) – for the Elastometal + Monoguard system in C5 High environment

- IBDiM Corrosion and Chemistry Department test results – for the Elastometal + Monoguard system in C5 High environment

- ISO 12944‑6 C5 High Certificate – for the Elastometal + Monoguard system in C5 High environment

- COT laboratory test results – for the Elastometal + Monoguard system in C5 High environment

- CoRI Test Report – for the Elastometal system: 1000h salt spray test, corrosion resistance, chemical resistance, temperature resistance, etc.

NRO Certificates – Non‑Fire‑Spreading Product

- ITB Classification Report – non‑fire‑spreading coating Broof(t1) – according to PN‑EN 13501‑5:2016, method 1

- Commercial Testing Company Report – very slow flame spread and low smoke emission – Class A – flame spread index 20 and smoke developed index 35 in ASTM E84 test

Safety and Environmental Certificates

- PZH Hygienic Certificate – confirmation of sanitary safety of the product

- Environmental Product Declaration (EPD) – life‑cycle assessment and environmental impact

- LEED, Green Seal – confirmation of low VOC content

- University of Ghent Report – suitable for use in the food industry; Belgium no. 6987 from 11.09.2002

- Red List, Living Building Challenge – manufacturer’s declaration confirming absence of Red List substances

Additional Materials

- Lead Encapsulant Test Certificate – ASTM E1795 Type III – formal, independent laboratory confirmation that the tested system meets the specification requirements for lead‑based paint encapsulation (within the scope of performed tests)

- Information Brochure – basic product information and benefits

- Reference List – example projects and applications

Notes:

Why does the can say that the paint weighs only 0.99 kg, 0.97 kg, or 0.93 kg?

The total weight of the paint consists of the weight of the base and the weight of the pigment.

- The weight of the base for a 1 kg package is as follows: base A 0.99 kg, base B 0.97 kg, base C 0.93 kg.

- Pigment weight for a 1 kg package:

- for light colors (base A and B), approx. 1-5% pigment is added,

- for dark colors (base C), approx. 5-10% pigment is added.

The total weight depends on the color, but is very close to 1 kg.

The exact weight of a 1 kg package, depending on the color, is presented in the table on the right/below.

The volume of 5 kg and 25 kg packages varies accordingly.

If you have any questions, please contact us.

f