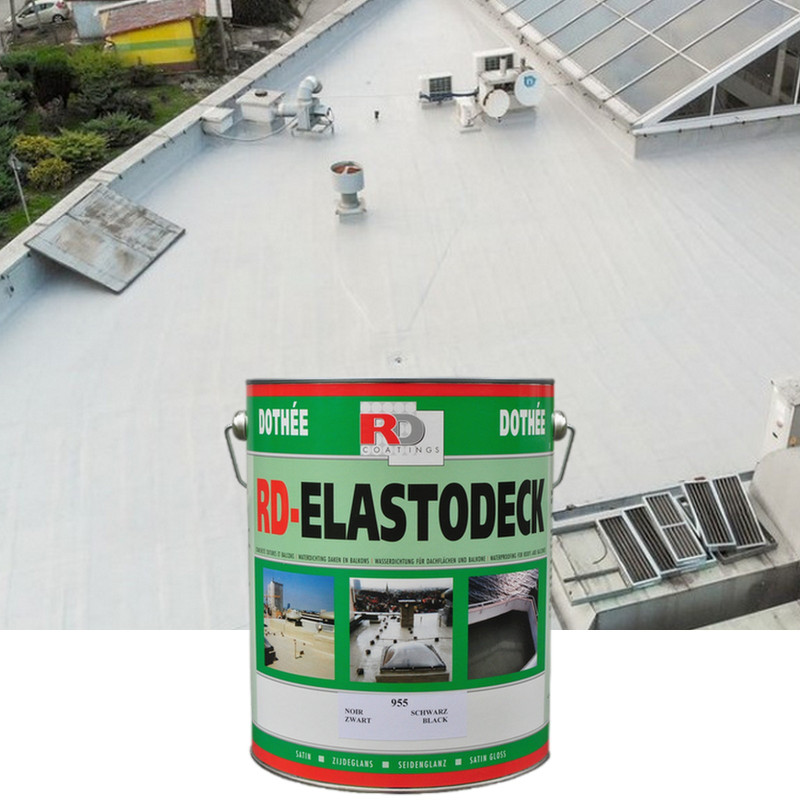

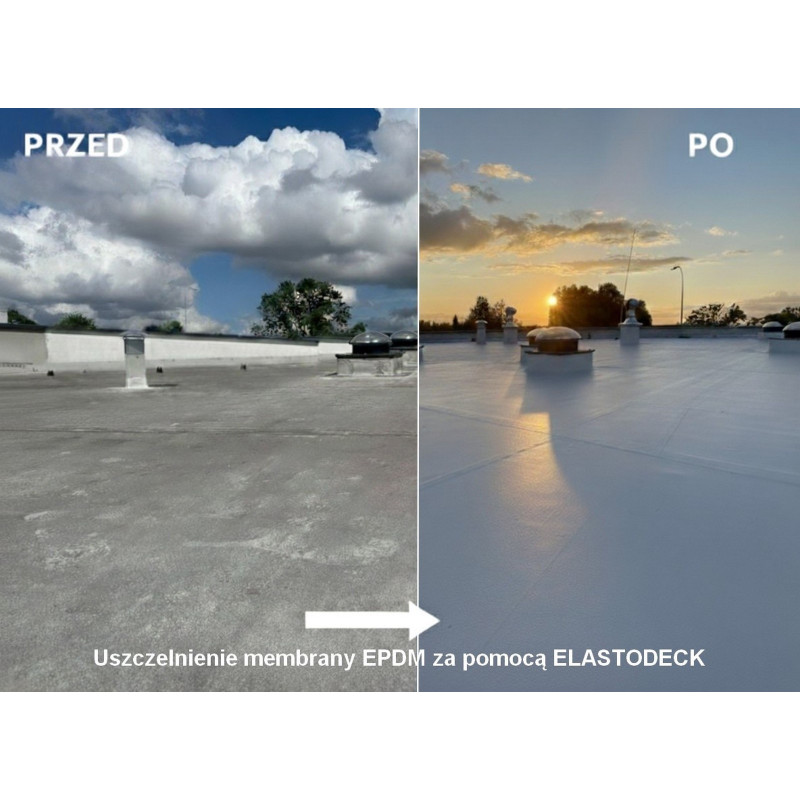

Seamless roofing - Elastodeck

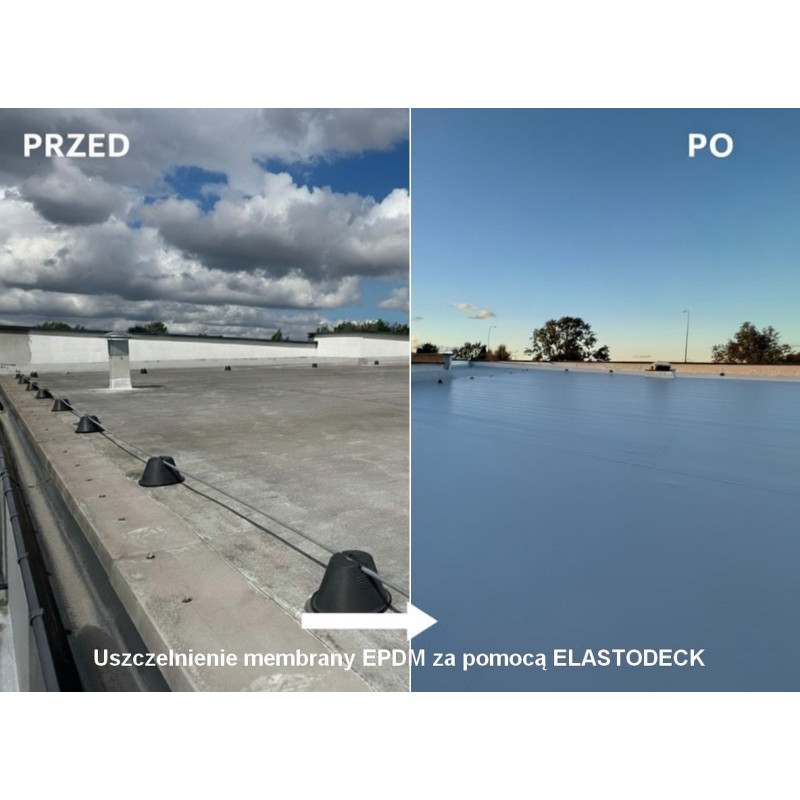

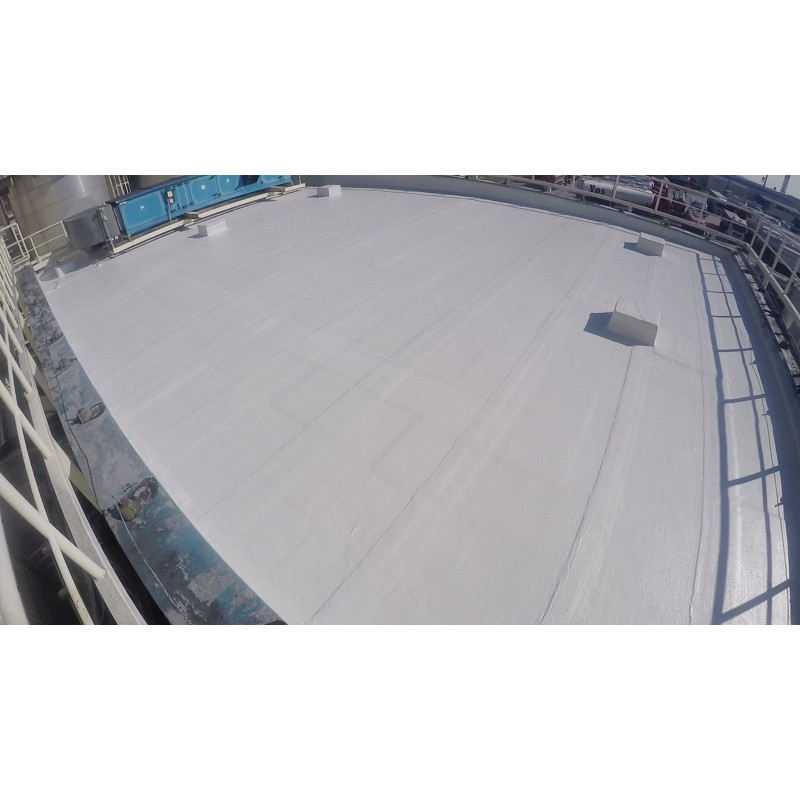

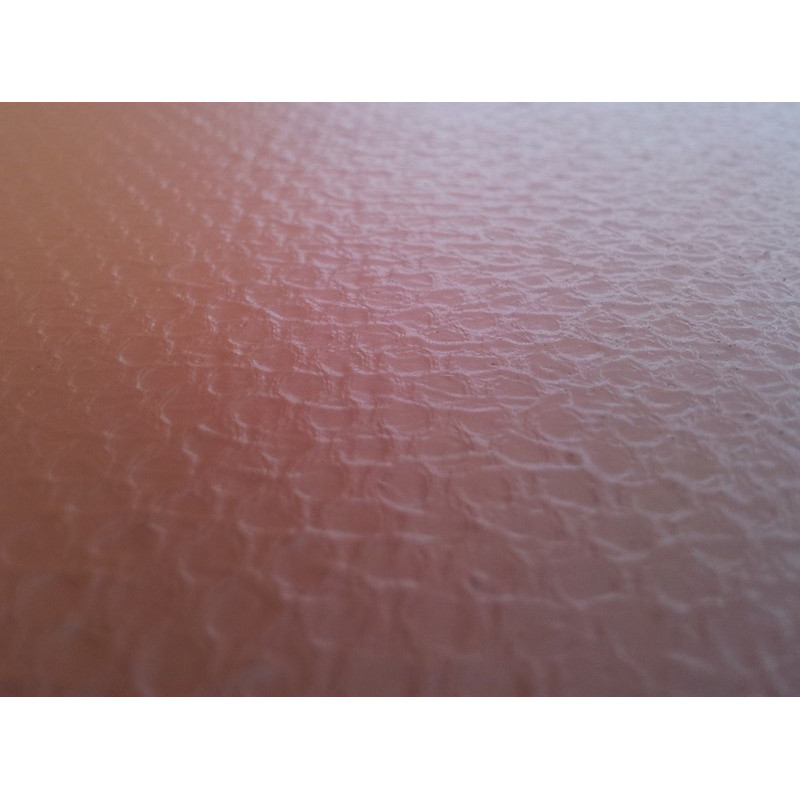

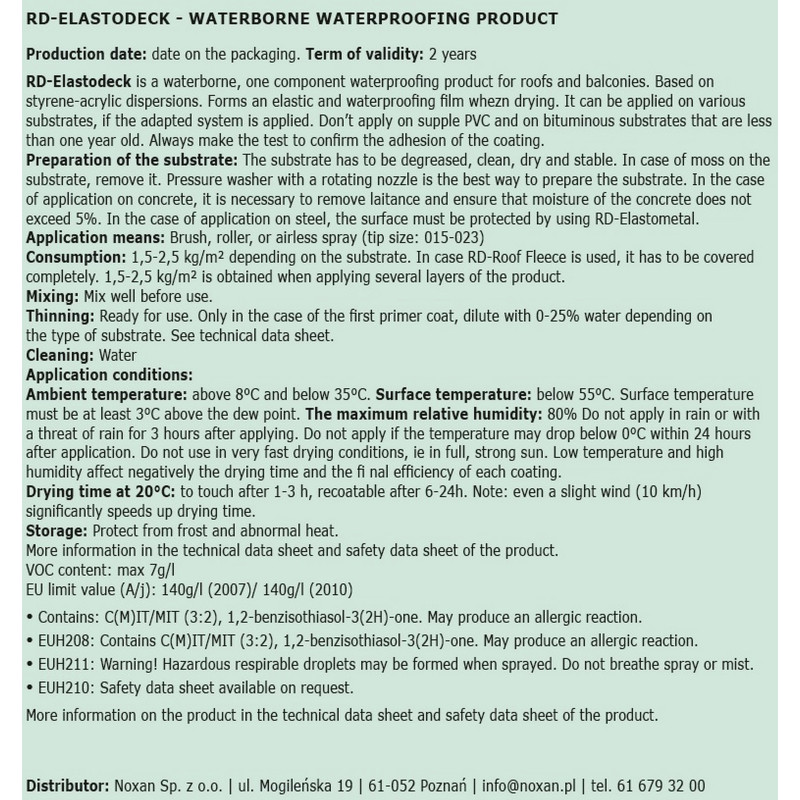

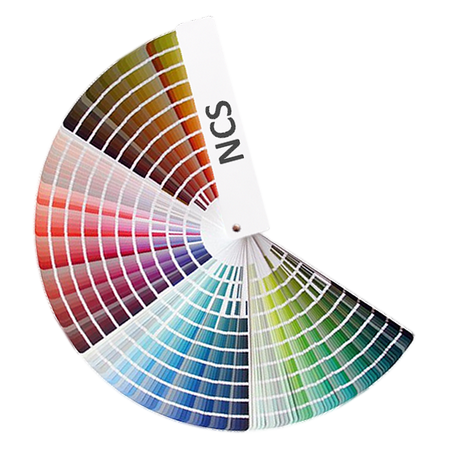

Elastodeck seamless roofing creates a durable, rubber-like coating with high elasticity. A semi-liquid product, extremely easy to use – applied with a roller or hydrodynamic gun onto a reinforcing fabric. Does not require removal of previous roofing. Creates a uniform (no joints), flexible (200%), durable, rubber-like roofing.

Features:

- seamless coating - no joints or seams - reduces potential leaks

- high elasticity 200% - reliable tightness at the points of contact between materials with different elasticity, e.g., steel and concrete, wood

- exceptional durability - possibility of obtaining a 10-year manufacturer's warranty for the tightness of the roof membrane *,

- high UV resistance - no cracking after years of use,

- resistance to weather conditions - snow, rain, extreme thermal loads - frost and high temperatures, air pollution, etc.,

- safe application and use - non-flammable paint, fire-retardant coating - ITB Classification Report NRO - PN-EN 13501-5:2016,

- easy application - single-component, water-soluble product free of toxic and flammable solvents,

- possibility of local repairs,

- aesthetic finish.

Consumption: 1.5 - 2 kg/m2

More information about Elastodeck seamless roofing.

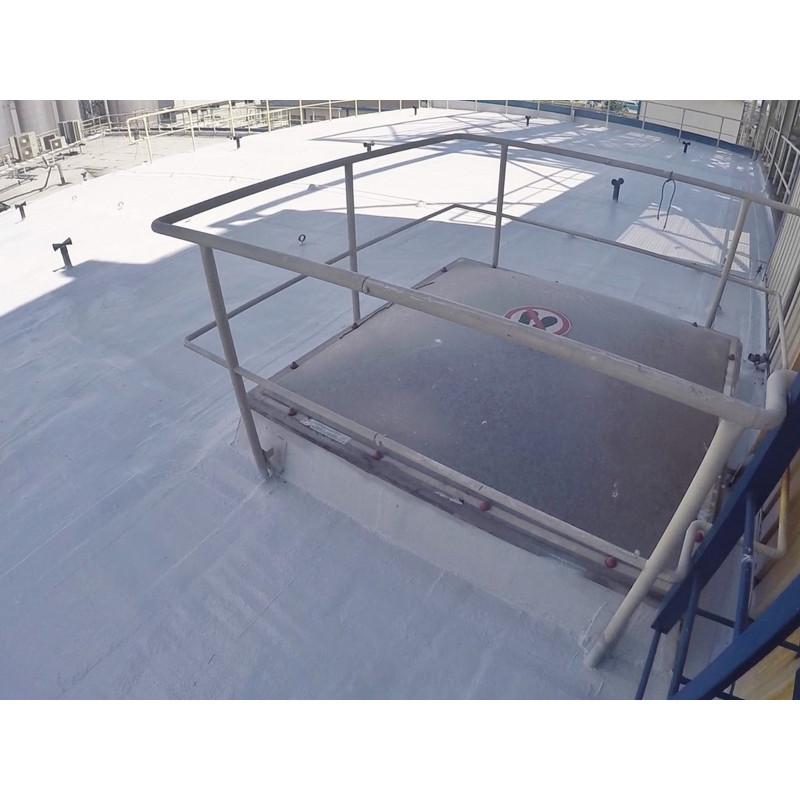

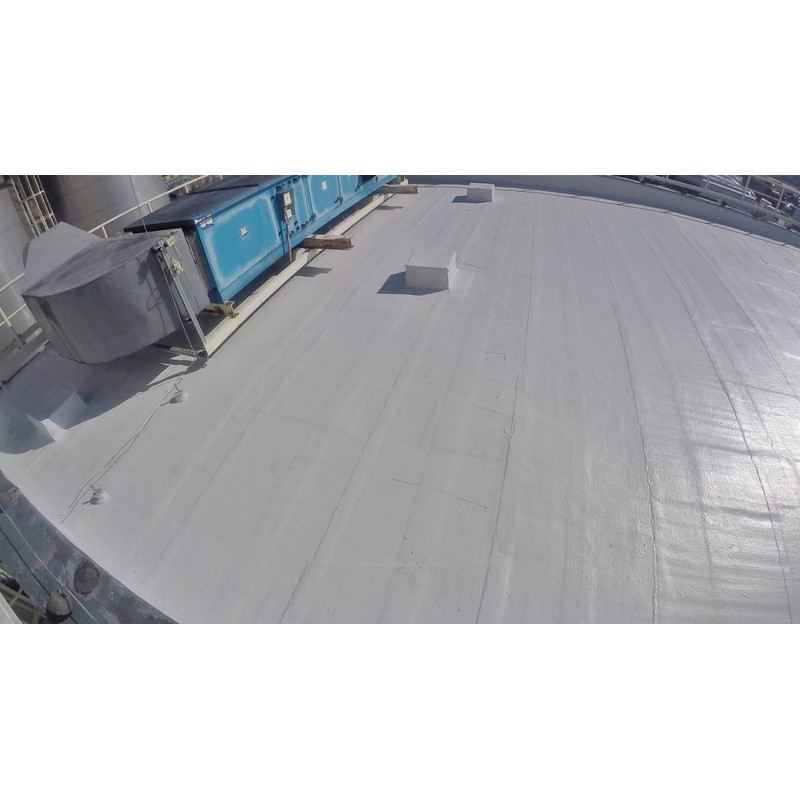

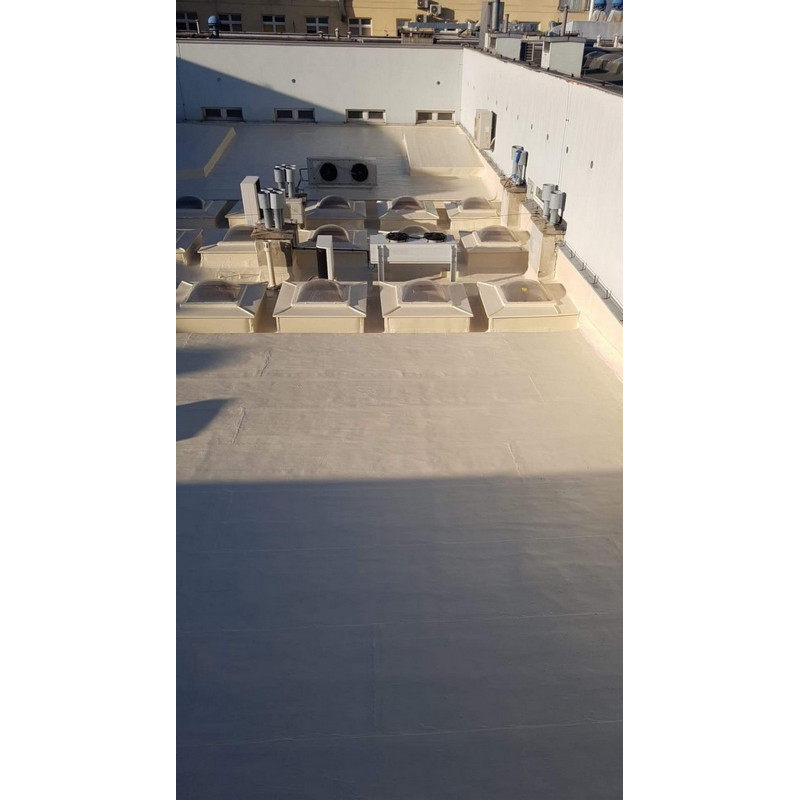

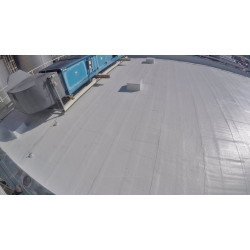

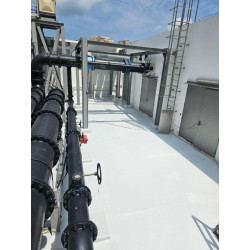

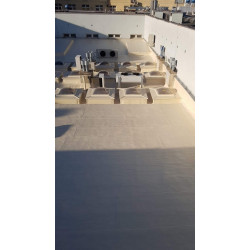

The perfect roofing solution for industrial roofs and more!

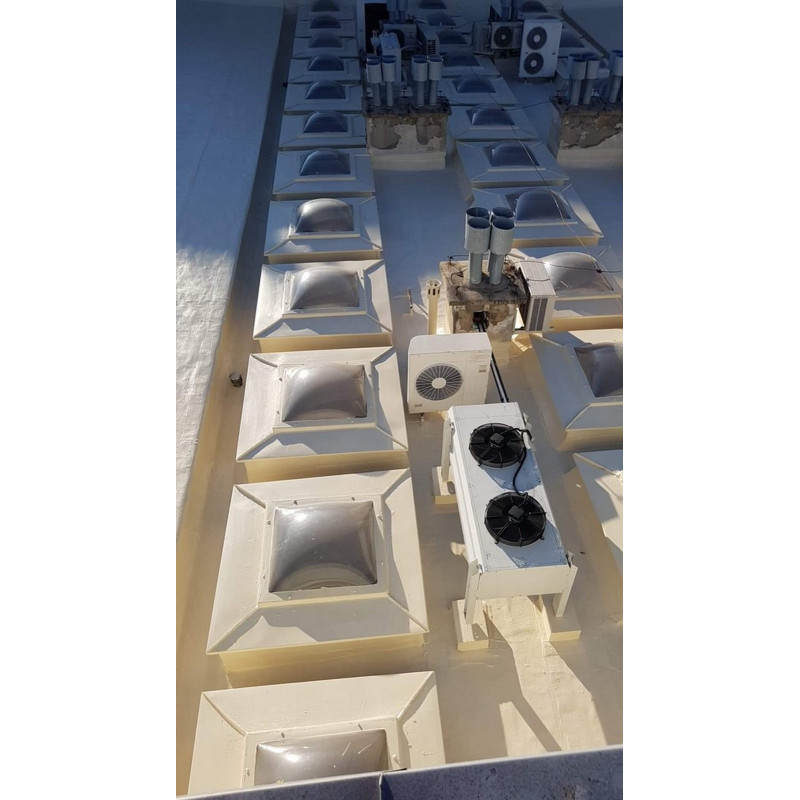

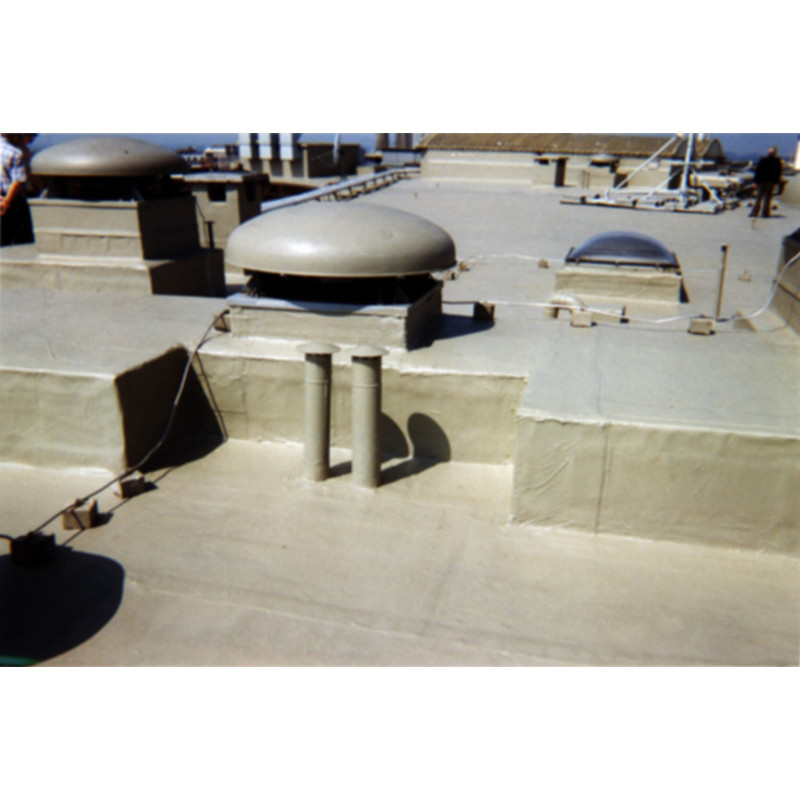

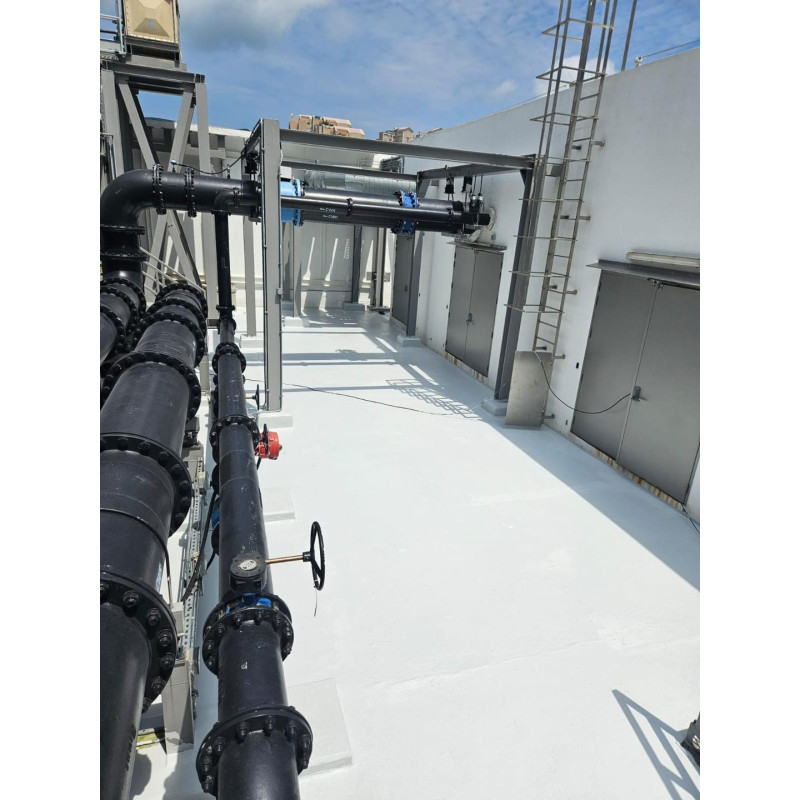

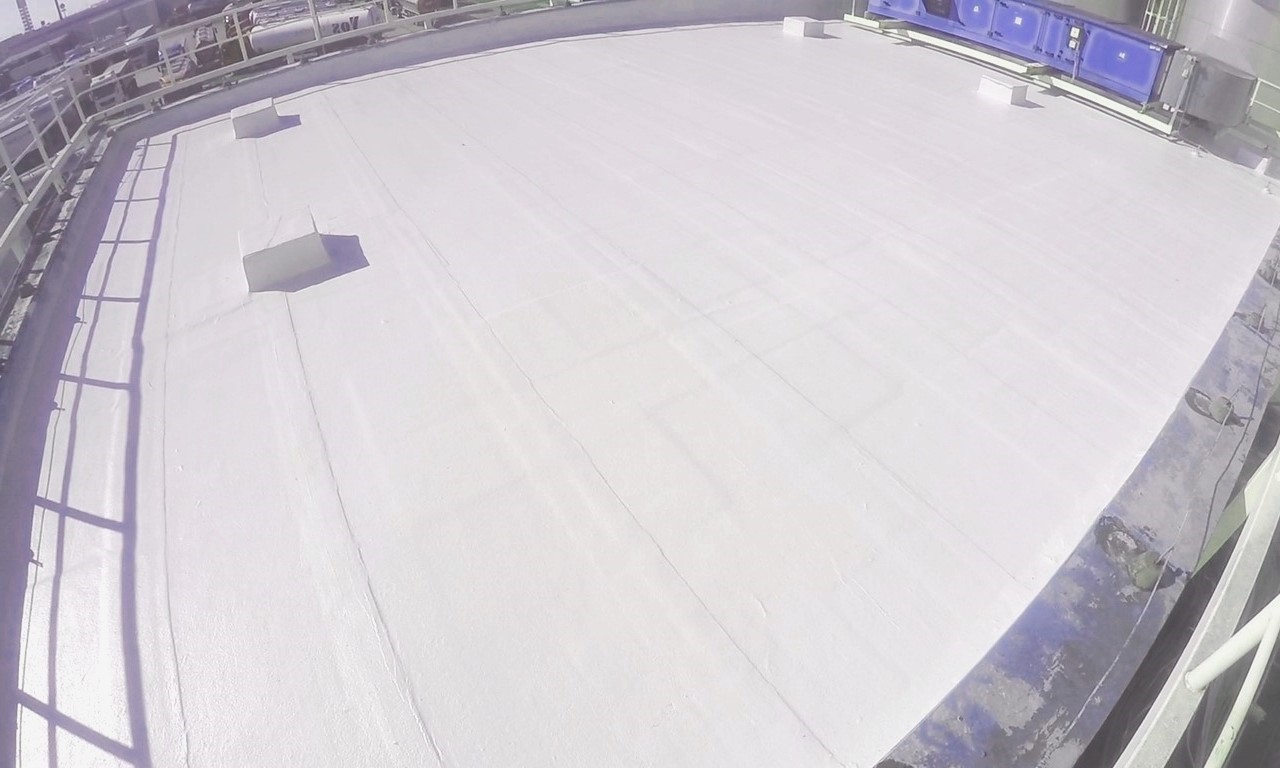

Elastodeck roofing is the ideal solution for industrial roofs, which often have many breaks and hard-to-reach areas. Thanks to its high flexibility and seamless coating, Elastodeck effectively protects even the most complex roofs, minimizing potential leak points. The resulting membrane is waterproof and has exceptional durability and resistance to extreme thermal loads, snow, frost, high temperatures, industrial air pollution, UV rays, etc.

The absence of joints ensures long-term watertightness on complex roofs.

Flexibility ensures permanent tightness in critical areas, e.g., at the junction of different materials.

Lightweight sealing (approx. 1 kg/m² of roof) does not overload the roof structure.

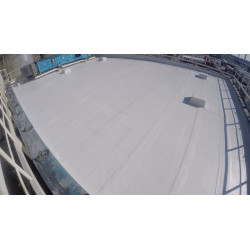

The light-colored membrane reflects more light and reduces the heating of the roof and building.

Watch the instructional video:

Easy-to-apply roofing.

Elastodeck roofing membranes are extremely easy to apply. They can be applied with a brush, roller, or airless spray.

For sealing sloping roofs, the application consists of two coats.

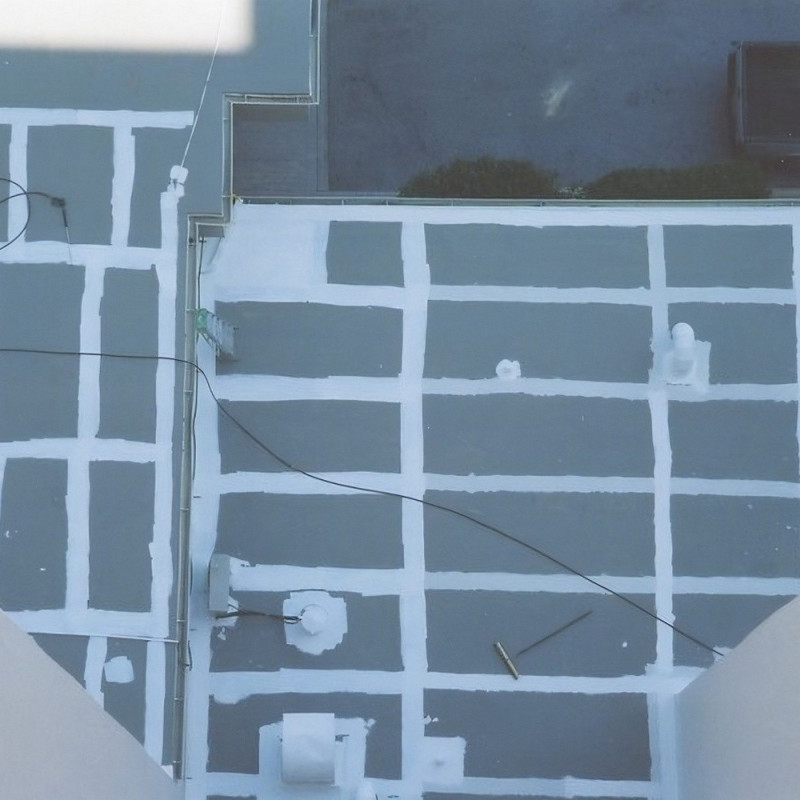

For flat roofs with long-term standing water or for bridging cracks, additional reinforcing fabric should be used. The fabric is laid out on the roof first. Then Elastodeck is applied until the fabric is completely covered.

Substrates:

Elastodeck roofing can be used on a wide variety of surfaces. Depending on the type of substrate, the first layer of Elastodeck can be diluted with water in appropriate proportions or a suitable primer should be used, as shown in the table below:

| Substrate | Recommended application |

|---|---|

| Old, seasoned roofing felt and other old bituminous substrates | directly, first layer diluted with 0-10% water |

| Bituminous shingles and so-called ondulina | directly, first coat diluted with 0-10% water |

| slightly absorbent concrete | directly, first coat diluted with 10% water |

| smooth, non-absorbent substrates, such as: mechanically troweled concrete, tiles, stoneware, terrazzo, stone, self-leveling screeds, old resin coatings | directly, first coat diluted with 25% water |

| OSB boards | directly, first coat diluted with 0-10% water |

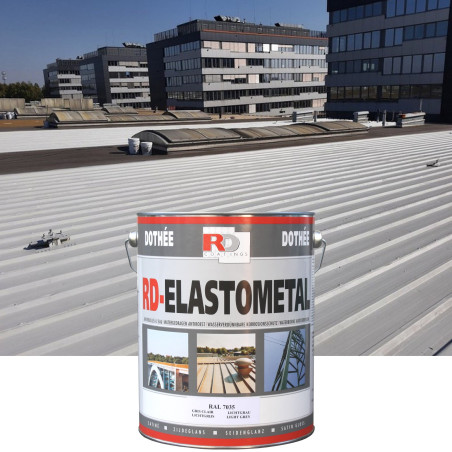

| steel, trapezoidal sheet metal | for additional corrosion protection, use Elastometal as a primer |

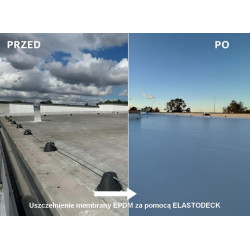

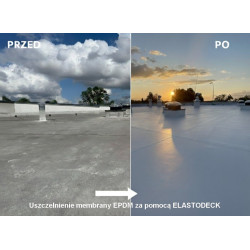

| EPDM, hard PVC | should be applied to RD-Repair primer diluted with 30% RR thinner |

We do not recommend application on soft PVC and bituminous substrates less than 1 year old.

Systems:

The table below shows which system should be used depending on the work to be performed:

| No. | Work | System per m2 | Cost | Photo |

|---|---|---|---|---|

| I. | Flat roof waterproofing | Reinforcing nonwoven fabric + min. 1.5 kg Elastodeck |

check the cost of the system |  |

| II. | Flat roof waterproofing and thermal protection | Reinforcing nonwoven fabric + min. 1.5 kg Elastodeck + 0.25 kg Thermoflex |

check the cost of the system |  |

| III. | Protection of sloped roofs | Min. 1.5 kg Elastodeck | check the cost of the system |  |

Instructional videos

Roof sealing with roofing felt – industrial, seamless, flexible, lightweight

How to renovate a roof made of bitumen shingles, bitumen panels, or Onduline?

How to renovate a roof made of asbestos-free eternit, corrugated sheets, fiber cement?

How to waterproof a terrace?

Waterproofing a concrete terrace

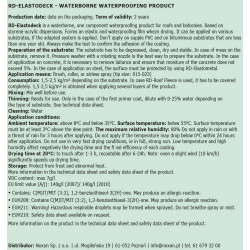

More colors:

Elastodeck seamless roofing

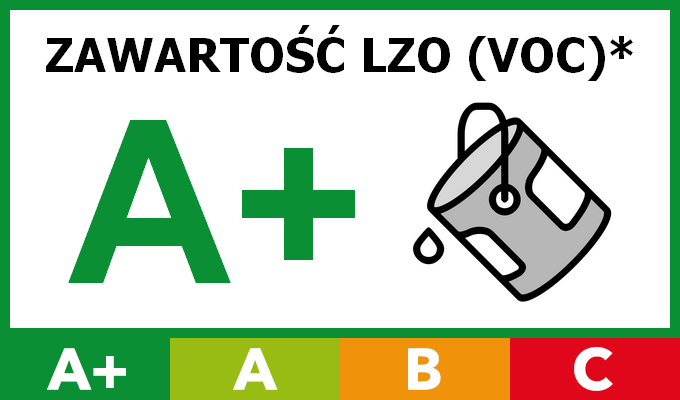

Volatile Organic Compound (VOC) content - 7 g/l

* Information on the level of vapor emissions (VOC) during application and until the paint is fully cured.

Emission levels from A+ (very low) to C (high).

Additional information on Volatile Organic Compounds.

Low-emission materials for LEED-certified buildings

Elastodeck roofing meets LEED v4 requirements for emissions and volatile organic compound content.

Documentation:

Documentation for Elastodeck

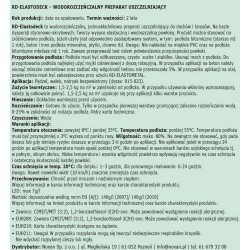

Datasheets

- Technical Data Sheet - detailed product properties and application method

- Safety Data Sheet - chemical, health and safety, and transport information

Application instructions

- Application instructions - a practical step-by-step application guide

Declarations

NRO certificates – non-fire-spreading product

- ITB Classification Report - non-fire-spreading coating Broof(t1) – regarding resistance to external fire exposure of a roof covered with the Elastodeck coating, in accordance with PN-EN 13501-5:2016, method 1, classifies the roof covering as non-fire-spreading (NRO).

Safety and environmental certificates

- LEED v4 compliance certificate for VOC emissions - tests confirming low VOC emissions after 28 days

- LEED, Green Seal - confirmation of low volatile organic compound content in the product

- Red List, Living Building Challenge - manufacturer’s declaration regarding the absence of Red List substances

Additional materials

- Reference list - example projects and applications

Documentation for Reinforcing nonwoven fabric

Datasheets

- Technical Data Sheet - detailed product properties and application method

Warranty information:

* A 10-year warranty for the tightness of the roof membrane is issued by the paint manufacturer RD-Coatings and the company performing the painting work. In order to obtain the warranty, the work must be inspected by RD-Coatings. The work must be carried out by an approved contractor in accordance with RD-Coatings' 10-year warranty procedures.