Hydropox OSB paint

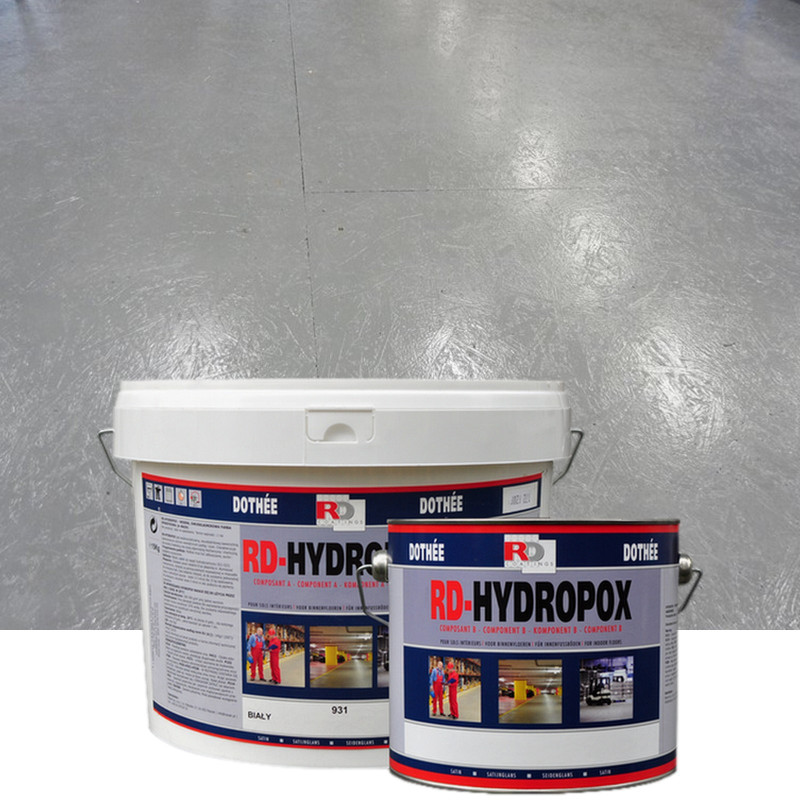

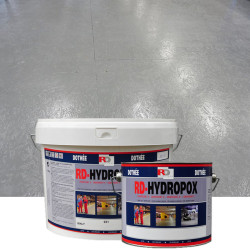

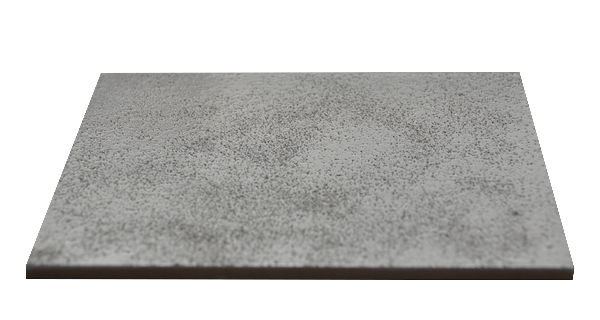

Hydropox is a two-component, water-based dispersion of epoxy resins, providing durable protection for floors and walls. The paint has very good chemical and mechanical resistance. It is characterized by high abrasion resistance. It creates an aesthetic coating with a satin finish. It is water-soluble, safe, and almost odorless during application - VOC: 0 g/l.

Hydropox is suitable for protecting surfaces made of OSB boards in areas with wheeled traffic and medium forklift traffic (several forklifts up to 8 hours a day), e.g., car repair shops, car washes, indoor parking lots, garages, etc.

Hydropox OSB paint - key properties:

- very hard, abrasion resistant

- highly chemically resistant - to oils, solvents, selected acids

- easily washable, satin finish

- approved for contact with food - certificate available

- suitable for protecting floors and walls in food production facilities - PZH hygiene certificate

- safe, virtually odorless during application - VOC: 0 g/l

- easy to apply – brush, roller, hydrodynamic drive

- applied in two coats (first coat diluted as a primer)

- for indoor use (for outdoor application, cover with HHP polyurethane topcoat to protect the color)

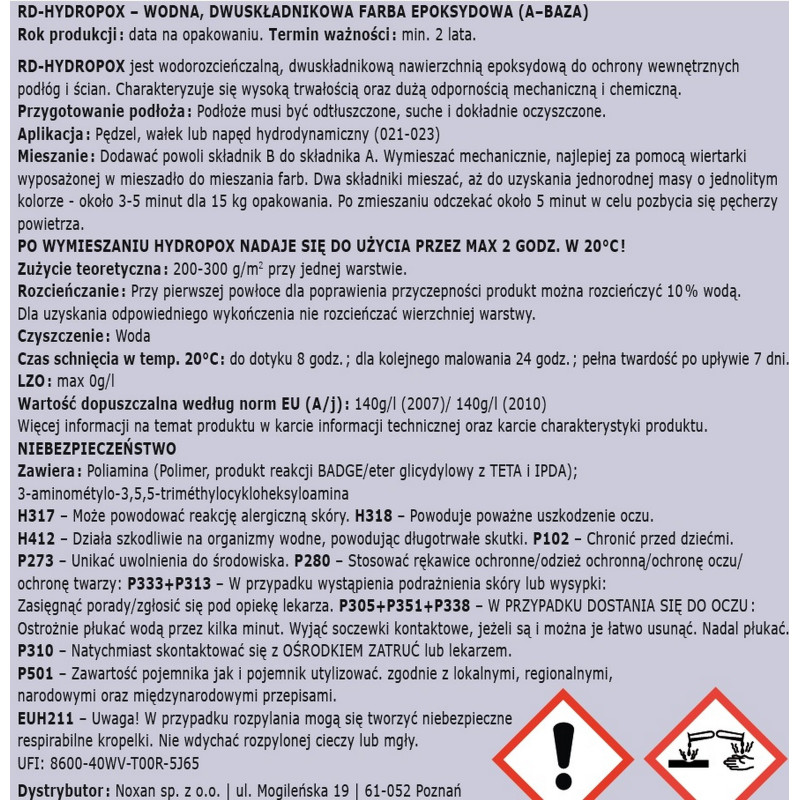

Coverage: 5-6 m²/kg per coat

More information about Hydropox OSB board paint.

More colors according to the RAL palette.

More colors according to the NCS palette.

One coat of Hydropox usually covers the entire surface. It protects it and makes it easy to wash. However, if the surface is exposed to motor vehicle traffic, contact with oil, water, or snow, we recommend applying two coats for long-lasting protection. Two coats provide a durable and aesthetic satin finish to the floor.

Hydropox is applied without a primer. The first coat, diluted with 10% water, creates a very well-adhering base. The second coat is not diluted.

Tips and tricks:

Paint for OSB boards with a decorative appearance

Decorative flakes scattered on resin floors mask unevenness and imperfections in the substrate and create an interesting aesthetic effect. The use of decorative flakes also provides an additional, slight anti-slip effect. The floor remains easy to clean.

We offer decorative flakes in various colors – see here.

Paint for OSB boards with anti-slip additive

The slip properties of Hydropox OSB board paint are similar to those of floor tiles. If the floor is usually dry, it is sufficient to use Hydropox without an anti-slip additive.

However, if the floor is exposed to frequent spills (water, oil, etc.), we recommend adding NS 200 anti-slip additive when applying the first coat of Hydropox (or sprinkling it on the first wet layer of Hydropox - see How to apply anti-slip additives). Then cover the entire surface with a second layer of Hydropox.

The system: Hydropox + NS 200 anti-slip additive + Hydropox has been tested for slip resistance in accordance with PN-EN 13036-4 and has obtained a pendulum roughness index PTV: 75 in dry conditions; 66 in wet conditions; R12.

Additional comments:

- Pay attention to the substrate. Depending on the smoothness and absorbency of the substrate, the final finish may vary.

- Please note that the anti-slip additive makes the floor finish rougher and less washable.

NS 200

anti-slip additive

Documentation:

Datasheets

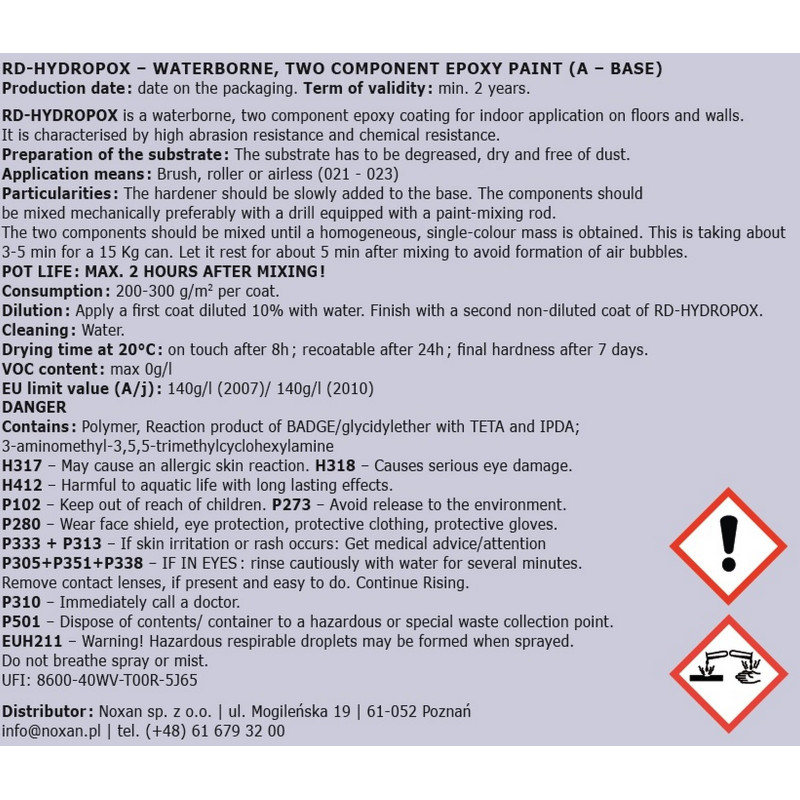

- Technical Data Sheet – detailed product properties and application method

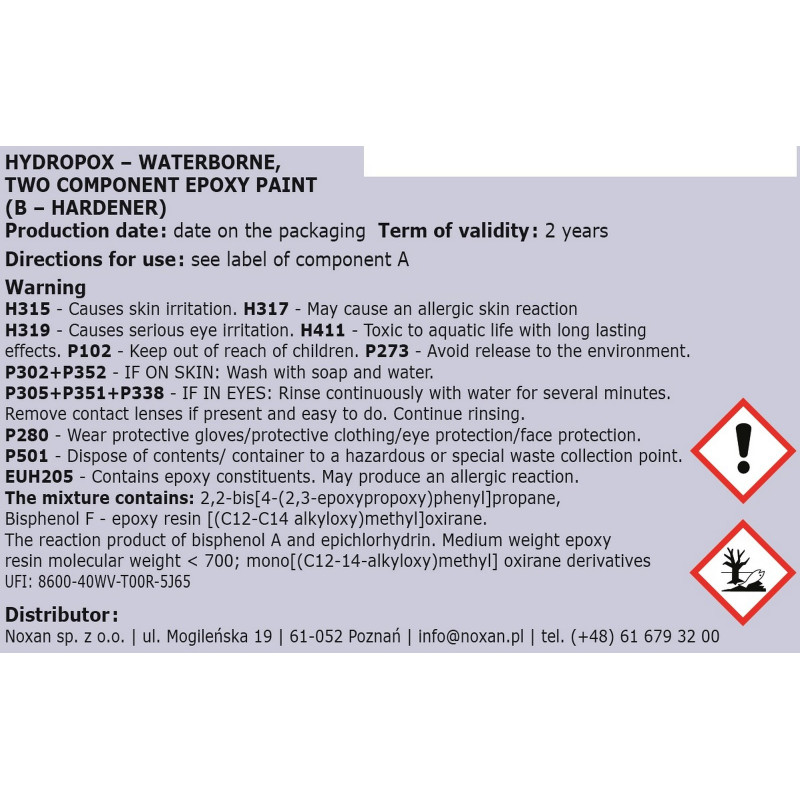

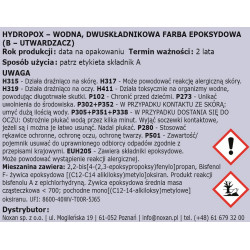

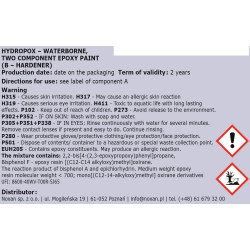

- Safety Data Sheet – base – chemical, health and safety, and transport information

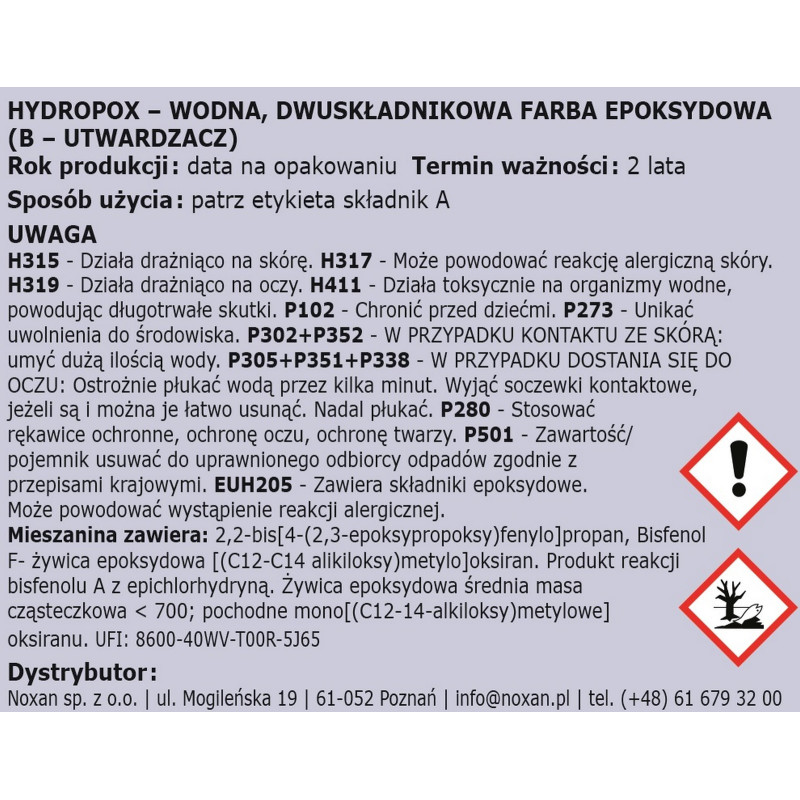

- Safety Data Sheet – hardener – chemical, health and safety, and transport information

Application instructions

- Application instructions – a practical step-by-step application guide

Declarations

Chemical and mechanical resistance

- Chemical resistance data sheet – results after exposure to selected substances

- Abrasion resistance test – Taber Abraser, ASTM D4060: CS-10 wheels, 1000 g load, 1000 cycles; mass loss: 0.109–0.121 g/1000 cycles (60–67 mg)

Certificates

- Slip resistance test report – results of PTV coefficient measurement (pendulum test)

Safety and environmental certificates

- PZH Hygienic Certificate – confirming that Hydropox may be used for professional protection of floors and walls in workshops, garages, production halls, food processing areas, showrooms, public utility buildings, and residential premises

- Ghent University Certificate – regarding compliance with the limits of European Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food

- LEED v4 compliance certificate for VOC emissions – tests confirming low VOC emissions after 28 days

- LEED, Green Seal – confirmation of low volatile organic compound content in the product

- Red List, Living Building Challenge – manufacturer’s declaration regarding the absence of Red List substances

Comments:

Why does the can say that the paint weighs only 0.99 kg, 0.97 kg, or 0.93 kg?

The total weight of the paint consists of the weight of the base and the weight of the pigment.

- The weight of the base for a 1 kg package is as follows: base A 0.99 kg, base B 0.97 kg, base C 0.93 kg.

- The weight of the pigment for a 1 kg package:

- for light colors (base A and B), approx. 1-5% pigment is added,

- for dark colors (base C), approx. 5-10% pigment is added.

The total weight depends on the color, but is very close to 1 kg.

The exact weight of a 1 kg package, depending on the color, is presented in the table on the right/below.

The volume of 4 kg and 15 kg packages varies accordingly.

If you have any questions, please contact us.