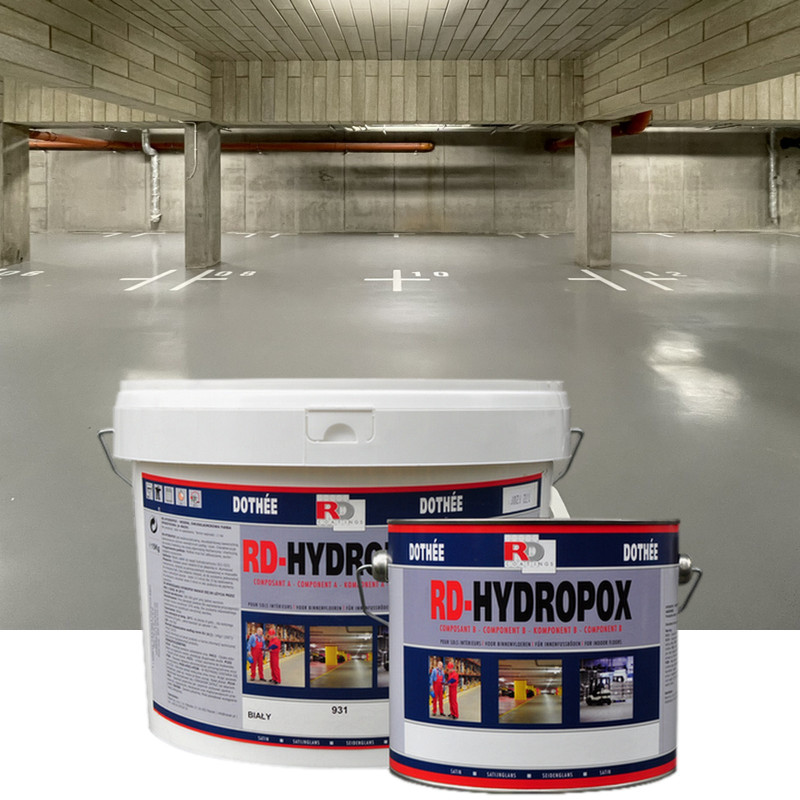

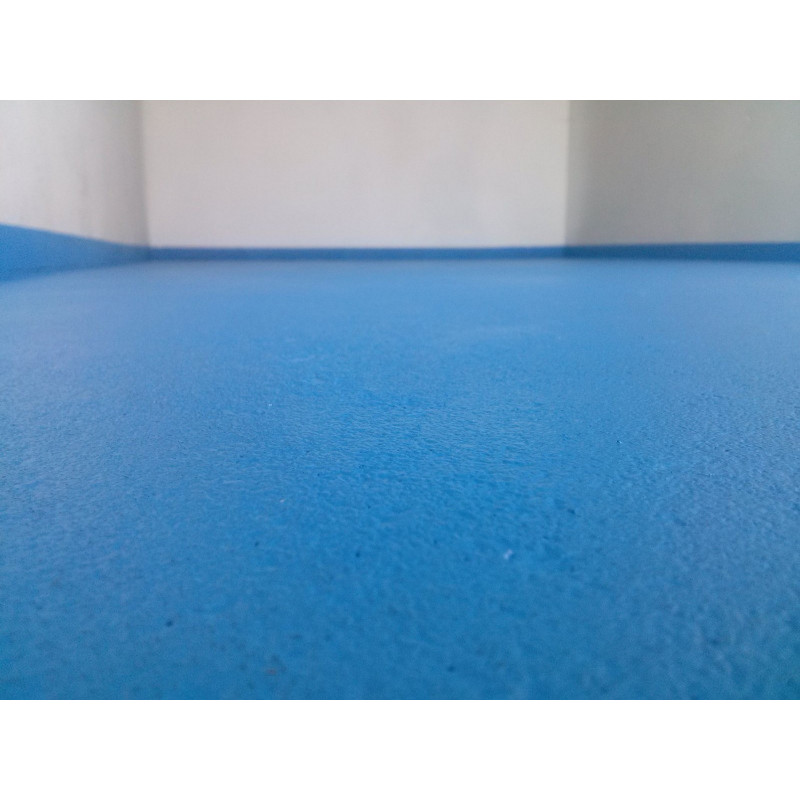

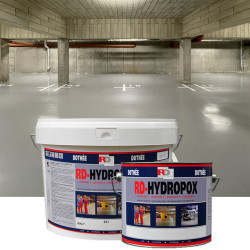

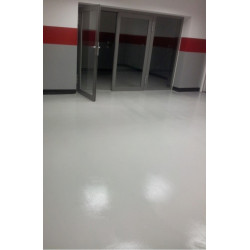

Garage flooring - Hydropox

Hydropox creates a durable floor protection. It has high chemical and mechanical resistance. It is a two-component, water-based dispersion of epoxy resins that creates a satin finish.

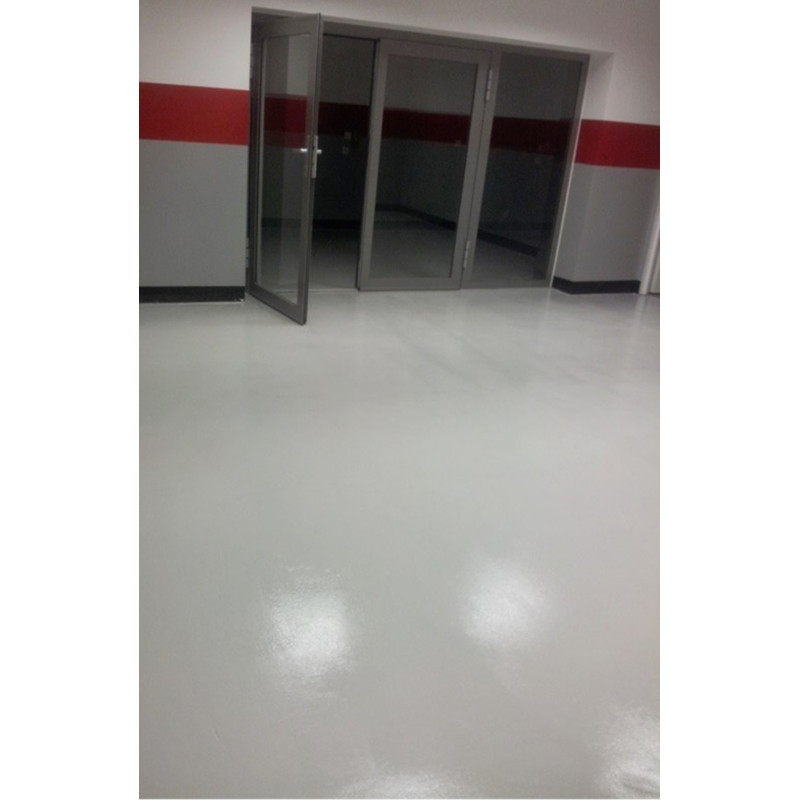

Hydropox flooring is safe and virtually odorless during application - VOC: 0 g/l. It is ideal for protecting floors in:

- car repair shops,

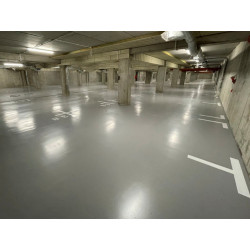

- indoor parking lots,

- garages,

- studios,

- showrooms,

- food production facilities,

- warehouses with light forklift traffic.

Hydropox flooring is suitable for use with several forklifts for up to 8 hours a day—for heavier use, we recommend ProFloor Plus flooring.

Hydropox epoxy flooring - key properties:

- two-component, water-based epoxy resin dispersion

- very hard and abrasion-resistant

- highly chemically resistant - to oils, solvents, selected acids

- easy-to-clean floor

- floor suitable for the food industry - PZH hygiene certificate and Gent certificate

- safe, virtually odorless during application - VOC: 0 g/l

Coverage: 4 - 5 m²/kg with one coat

Standard system for medium-absorbent substrates: 2 x Hydropox 5 m²/kg

More information about Hydropox garage flooring.

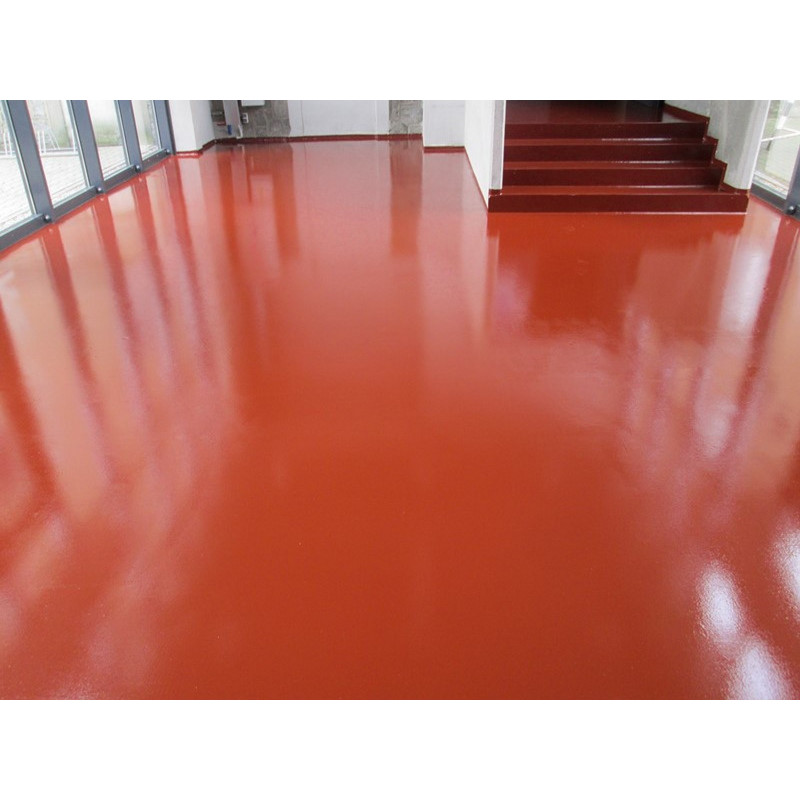

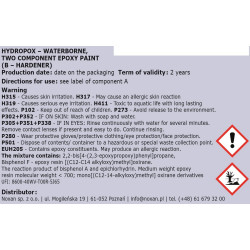

More colors:

Instructional video:

We invite you to watch an instructional video showing the application of Hydropox epoxy flooring when protecting a garage floor.

Garage floor - Hydropox epoxy resin

Systems:

| Floor type: | Example: | System: | Photo: |

| Non-absorbent smooth floors | Resins, tiles, terrazzo - exposed to light and medium loads | 1 x RO 3333 primer 25 m²/l + 2 x Hydropox 5 m²/kg |

|

| Non-absorbent rough floors | Mechanically troweled or hand-troweled compacted concrete, rough resinous quartz carpets | 2 x Hydropox 5 m²/kg |  |

| Medium-absorbent floors | Self-leveling screeds, mechanically troweled compacted concrete without surface hardening* | 1 x HP Primer W221 8 m²/kg + 2 x Hydropox 5 m²/kg |

|

| Absorbent concrete floors | Non-compacted concrete, mechanically troweled to a rough finish or hand-troweled, semi-dry concrete, e.g., mixcrete floors | 2 x Hydropox 4 m²/kg |  |

| Demanding floors | Fresh, damp concrete; floors cleaned of oil residues; smooth substrates such as terrazzo, resins, tiles - exposed to heavy loads | 1 x HeavyBond 30-33 primer 4 m²/kg + 2 x Hydropox 4 m²/kg |

|

Information on the application of Hydropox epoxy flooring:

In most cases, Hydropox garage flooring is applied without a primer. The first coat, diluted with 10% water, creates a very well-adhering primer. The second coat is not diluted. However, in the case of:

- medium-absorbent floors (e.g., self-leveling screeds, mechanically troweled smooth concrete), HP Primer W221 should also be used.

- compact, non-absorbent floors (e.g., resins, tiles, terrazzo) exposed to light and medium loads - additionally apply RO 3333 primer,

- compact, non-absorbent floors exposed to heavy loads and demanding floors (e.g., fresh, damp concrete) – additionally apply HeavyBond 30-33 primer.

Hydropox epoxy floors, like other epoxy resins, have incomplete UV resistance. Light colors, especially white, exposed to sunlight and heat may yellow over time. To fully reduce the yellowing effect, Hydropox should be finished with Hydrograff HP varnish.

The above Hydropox garage flooring systems are general recommendations. Each project should be treated individually. If you have any doubts, please contact us so that we can select the right system for your specific floor.

Tips and advice:

How to make a garage floor?

If you are wondering how to protect your garage floor, please read our specially prepared technical advice. In the article, we show you how to apply Hydropox garage flooring step by step and more. Along with photos, we also present important technical issues.

You can find the link to the advice here.

We hope you enjoy reading it, and if you have any questions, please contact us.

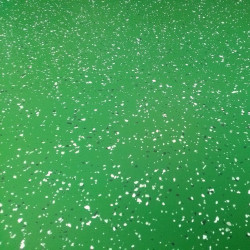

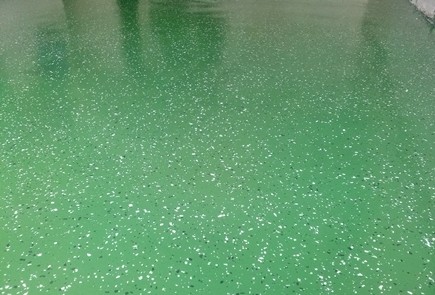

Epoxy floor with a decorative appearance

Decorative flakes scattered on resin floors help to mask unevenness and imperfections in the substrate and create an interesting aesthetic effect. The use of decorative flakes also provides an additional, slight anti-slip effect. The floor remains easy to clean.

We offer decorative flakes in various colors - see here.

Epoxy floor with anti-slip additive

The slip properties of Hydropox garage flooring are similar to those of floor tiles. If the floor is usually dry, it is sufficient to use Hydropox without an anti-slip additive.

However, if the floor is exposed to frequent spills (water, oil, etc.), we recommend adding NS 200 anti-slip additive when applying the first coat of Hydropox (or sprinkling it on the first wet layer of Hydropox - see How to apply anti-slip additives). Then cover the entire surface with a second layer of Hydropox.

The system: Hydropox + NS 200 anti-slip additive + Hydropox has been tested for slip resistance in accordance with PN-EN 13036-4 and has obtained a pendulum roughness index PTV: 75 in dry conditions; 66 in wet conditions; R12.

Additional comments:

- Pay attention to the substrate. Depending on the smoothness and absorbency of the substrate, the final finish may vary.

- Please note that the anti-slip additive makes the floor finish rougher and less washable.

NS 200

anti-slip additive

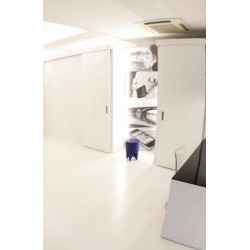

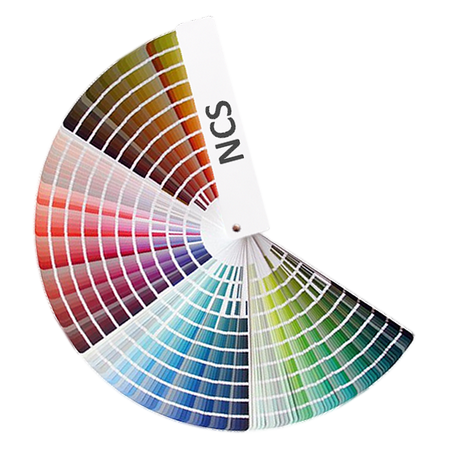

Polyurethane varnish finish

Hydropox epoxy flooring provides a very aesthetic satin finish. Hydropox is a suitable solution for most halls, warehouses, garages, and parking lots.

In places where aesthetics are particularly important, e.g., exhibition halls, showrooms, etc., Hydrograff HP polyurethane varnish can be used for finishing. Hydrograff HP reduces scratches on the floor and increases its resistance to abrasion and UV radiation. The varnish also allows you to obtain a resin floor in 3 finishes: gloss, satin, and matte.

For more information on Hydrograff HP polyurethane varnish, see here.

Documentation:

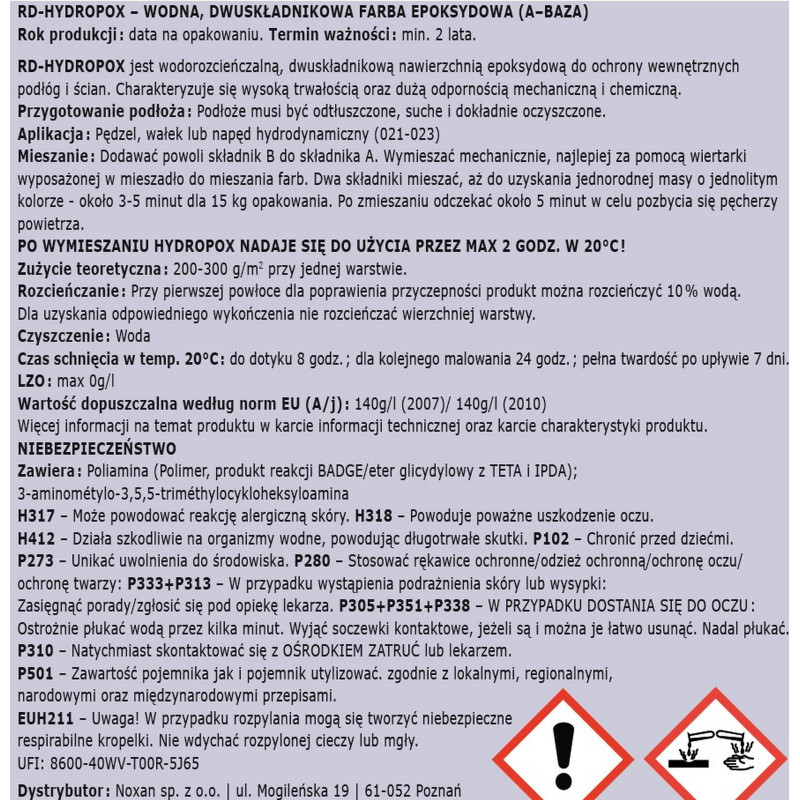

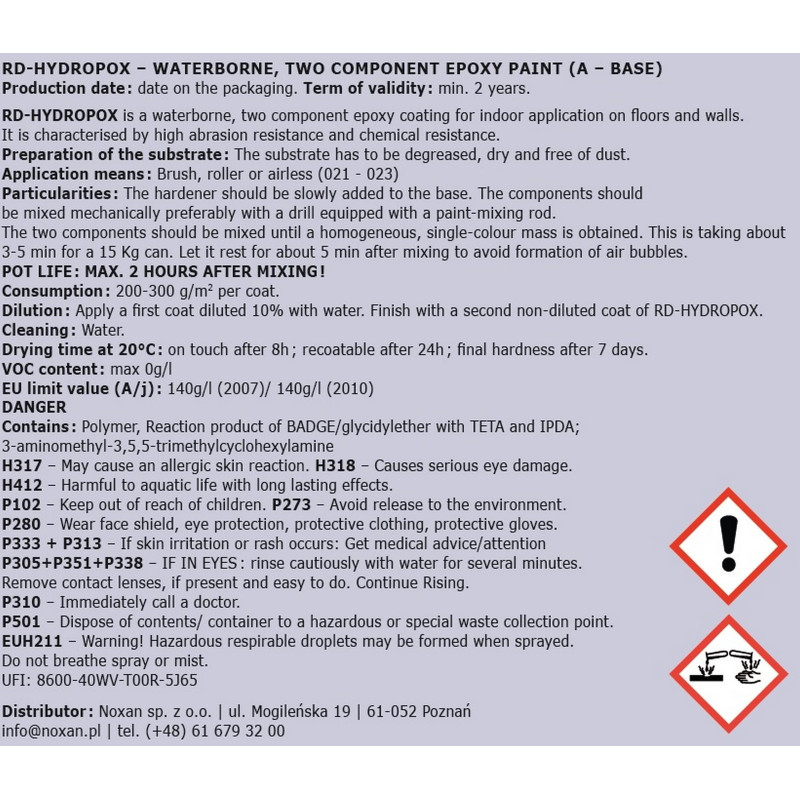

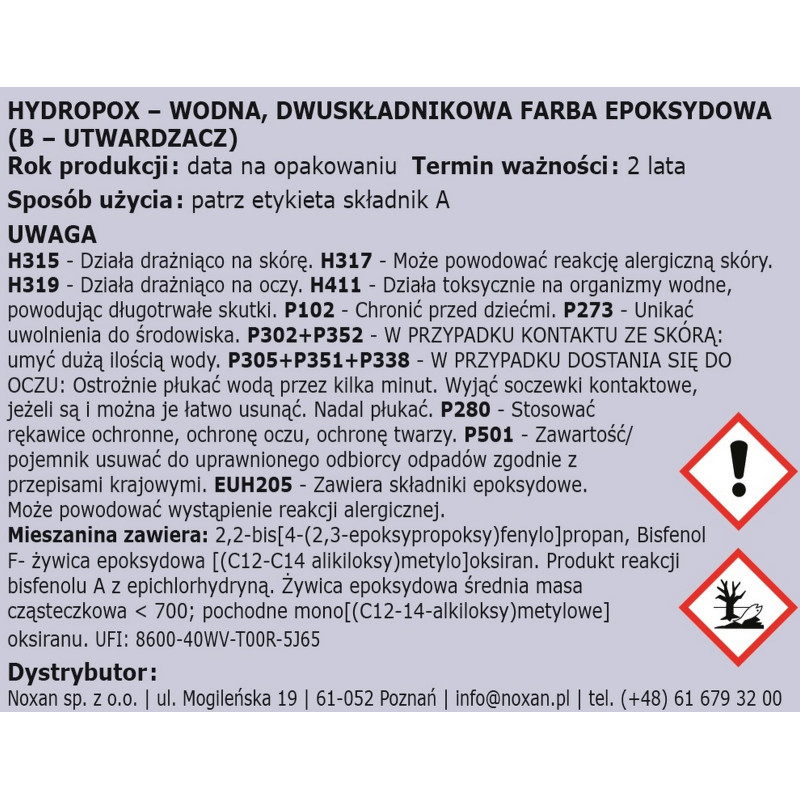

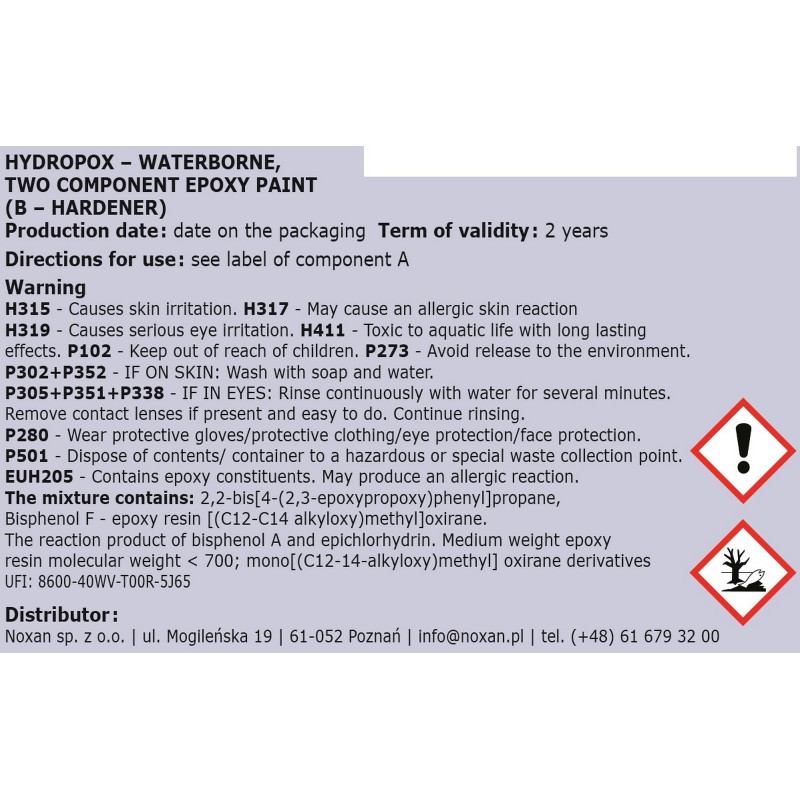

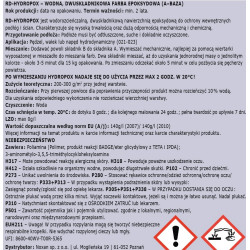

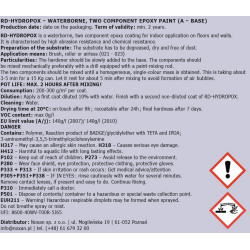

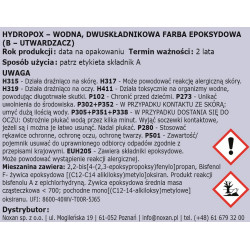

Datasheets

- Technical Data Sheet - detailed product properties and application method

- Safety Data Sheet - base - chemical, health and safety, and transport information

- Safety Data Sheet - hardener - chemical, health and safety, and transport information

Application instructions

- Application instructions - practical step-by-step application guide

Declarations

Chemical and mechanical resistance

- Chemical resistance sheet - results after exposure to selected substances

- Abrasion resistance sheet - Taber Abraser, ASTM D4060: CS-10 wheels, 1000 g load, 1000 cycles; weight loss: 0.109–0.121 g/1000 cycles (109–121 mg)

Certificates

- Slip resistance test report - PTV coefficient measurement results (pendulum test)

Safety and environmental certifications

- Food contact certificate - Hydropox is suitable for contact with water for an indefinite period at room temperature

- PZH Hygiene Certificate - confirming that Hydropox may be used for: professional protection of floors and walls in workshops, garages, production halls, food production premises, showrooms, public utility buildings, residential premises

- LEED v4 VOC emissions compliance certificate - tests confirming low VOC emissions after 28 days

- LEED, Green Seal - confirmation of low volatile organic compound (VOC) content in the product

Comments:

Why does the can say that the paint weighs only 0.99 kg, 0.97 kg, or 0.93 kg?

The total weight of the paint consists of the weight of the base and the weight of the pigment.

- The weight of the base for a 1 kg package is as follows: base A 0.99 kg, base B 0.97 kg, base C 0.93 kg.

- The weight of the pigment for a 1 kg package:

- for light colors (base A and B), approx. 1-5% pigment is added,

- for dark colors (base C), approx. 5-10% pigment is added.

The total weight depends on the color, but is very close to 1 kg.

The exact weight of a 1 kg package, depending on the color, is presented in the table on the right/below.

The volume of 4 kg and 15 kg packages varies accordingly.

If you have any questions, please contact us.