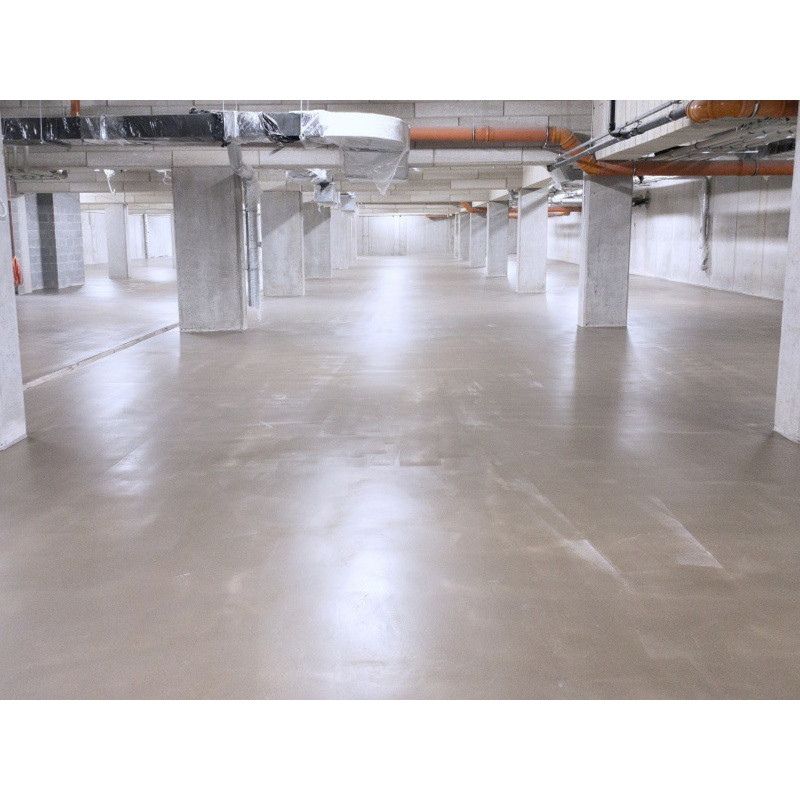

Epoxy primer/impregnant - HP Primer W221

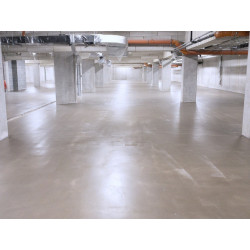

HP Primer W221 is a highly durable, water-based, two-component epoxy with excellent adhesion to various difficult surfaces. It can be applied to concrete, asphalt, as well as difficult-to-coat, smooth surfaces such as ceramic tiles and self-leveling screeds.

The highly durable HP Primer W221 primer is designed for use as an epoxy varnish for colorless floor finishing or as a primer for the highly durable ProFloor Plus epoxy floor.

Highly durable HP Primer W221 epoxy primer/impregnating agent – key properties:

- durable, two-component epoxy (2K)

- excellent adhesion to various surfaces, including difficult ones, such as many self-leveling screeds

- used as a primer, it acts as an adhesive barrier between old and new coatings

- when used as a varnish, it protects against dust, dirt, water, oil, and solvents

- can be used under surfaces intended for heavy mechanical traffic

- water-soluble - has a weak odor during application

- ideal for use in areas where solvents cannot be used

- can also be applied to walls

- provides a satin finish

Coverage: 7-10 m²/kg (7 m²/kg for a dry layer thickness of 52 µm)

More information about HP Primer W221 epoxy primer/impregnating agent.

Note:

The gray color is only available in 5 kg packages.

Key properties:

Product characteristics

- two-component,

durable epoxy (2K), - ideal for areas where solvents cannot

be used,

Resistance

- can be used under surfaces

intended for heavy mechanical traffic,

Aesthetics

- available in transparent

and gray versions, - provides an aesthetic

satin finish,

Application and safety

- has excellent adhesion to difficult substrates

of many self-leveling anhydrite and cement compounds, - is water-soluble,

has a low odor during application, - safe for people and the environment,

has low VOC content, making it safe for people and the environment, - for best results, we suggest

using a nylon roller for epoxy paints - 14 mm,

General recommendations regarding the specifications of self-leveling screeds

Self-leveling screed under resin substrates should have a minimum compressive strength of 25 MPa (C25). The screed should not contain any additives that hinder adhesion, such as latex. Another parameter that helps in the assessment is the peel strength of the substrate, which should be at least 1.5 MPa.

Below is a list of compounds for which adhesion to the substrate has been confirmed in tests and in practice.

HP Primer can be applied to self-leveling screeds:

- cementitious:

- Uzin: NC 150, NC 170 LevelStar NEW, NC 172 BiTurbo, NC 196 NEW

- Bostik: Cempolay Ultra Strong

- Flowcrete: Industrial Top

- F-Ball: Stopgap 800 Wearcoat

- Sika®: SikaScreed® HardTop-60

- anhydrite:

- Knauf: FE50

- Uzin: NC 110, NC 115, NC 118, NC 112

HP Primer SHOULD NOT be used on self-leveling screeds:

- cementitious:

- Bostik: Cempolay Self Levelling, Cempolatex

- Mapei: Ultraplan series

- Sika®: mortars with SikaLatex® additive

- anhydrite screeds:

- Atlas: SAM 100, SAM 200, SAM 500, SWS 201

Instructional videos:

Resin and epoxy flooring in halls and warehouses – How to do it?

Resin for self-leveling, mineral screeds

Documentation:

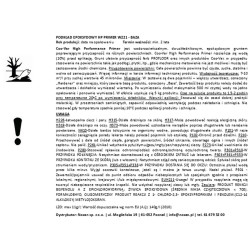

Datasheets

- Technical Data Sheet – detailed product properties and application method

- Safety Data Sheet – base – chemical, health and safety, and transport information

- Safety Data Sheet – hardener – chemical, health and safety, and transport information

Customers who bought this product also bought:

Eco-friendly wall paint Ecomat - RAL colors from the mixer

Resin mixer

DoPox® HardCoat 30-52 - solvent-free epoxy resin

Concrete repair resin - Rompox 1505 + quartz

GALVA ZINC 2185 zinc spray

Chemical resistant epoxy enamel - Rust-Oleum 5500

3M painter's tape

You might also like

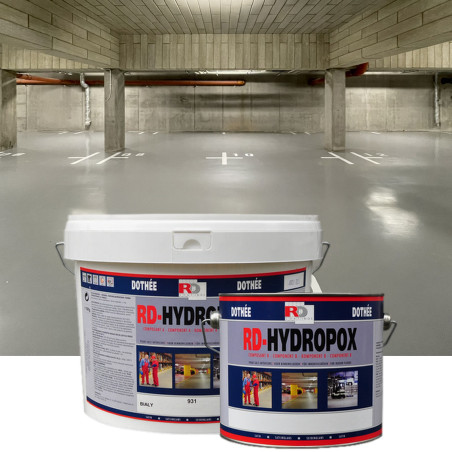

Garage flooring - Hydropox

High-strength epoxy flooring - ProFloor Plus

Nylon paint roller 14 mm - 70 cm, 38 cm, 30 cm, 25 cm, 11 cm

-

Colorless

-

gray BS 00 A 05 ok. RAL 7035

zł221.40 brutto

zł180.00 zł netto

zł221.40 brutto za 1 kg

zł221.40 brutto

zł180.00 zł netto

zł221.40 brutto za 1 kg