Paint for cold stores, freezers - DoPox® QuickCoat 40-10

Paint for cold stores and freezers DoPox® 40-10 QuickCoat is a two-component, fast-drying polyurea resin for finishing floors and floorings, suitable for use at temperatures as low as -20°C. It can be used both indoors and outdoors.

The special formula of QuickCoat 40-10 allows multiple coats to be applied in a single day, enabling renovation work to be completed quickly without unnecessary downtime (check application and drying times).

QuickCoat 40-10 cold room paint is characterized by very high chemical and mechanical resistance. The paint is suitable for use in rooms with heavy forklift traffic. It is resistant to frequent chemical cleaning, spills of many different oils, alkalis, and even acids. Thanks to its very high UV resistance, the applied coating does not yellow or lose its gloss over a long period of use.

QuickCoat 40-10 is a safe product to use. It does not contain VOCs (VOC = 0), so it does not emit unpleasant odors during application. The absence of solvents in its composition makes it non-flammable and does not pose a fire hazard.

The colorless version is sold in packages of 1 kg, 5 kg, and 16.5 kg.

The colored version is sold in packages of 1.1 kg, 5.5 kg, and 18.15 kg.

Consumption: 0.15 kg/m² per coat

More information about QuickCoat 40-10 cold room paint.

Coming soon!

More colors according to RAL and NCS

Key features:

High resistance

- Very high mechanical resistance,

the paint is suitable for floors with heavy forklift traffic. - very high chemical resistance,

the resin is resistant to many different oils, alkalis, and even acids, - resistance to frequent washing with chemical

detergents, - very high UV resistance,

the resin does not tarnish or yellow over long periods of use,

Fast drying time

- very fast drying time,

allows renovation work to be completed in one day, - possibility of even faster drying by adding

1-2% water, - time for use of the material in the standard version: 6 minutes (check

usage/drying times),

Safe application

- water-soluble, does not contain VOCs (0 VOCs),

does not emit unpleasant odors during application, - does not contain solvents,

the product is non-flammable during application, no fire hazard, - application with a roller (or brush),

- suitable for use at low temperatures from -20°C,

both indoors and outdoors, - has a PZH hygiene certificate confirming

its suitability for professional use in industrial, public, and commercial facilities, production halls (including food production facilities), residential premises, garages, and wet areas,

Aesthetic finish

- smooth gloss finish,

- the applied coating is easy to keep clean,

- quick repairs possible

in case of local damage.

Systems:

| System type: | System per m2: | Cost per m2: |

|---|---|---|

| Heavy-duty system | 1 x 0.25 kg - 0.3 kg QuickBond 30-35 primer + 2.5 kg dried quartz (gradation 0.1 - 0.3 mm) + 1 x 0.5 kg QuickCoat 40-10 resin |

check cost |

| System for medium loads | 2 x 0.15 kg QuickCoat 40-10 resin | check the cost |

The systems presented are general recommendations. Each project should be treated individually. If you have any doubts, please contact us so that we can select the right system for your specific problem.

Usage and drying times:

QuickCoat, a fast-drying polyurea resin, offers the possibility of adjusting the curing time. Drying can be accelerated by adding water, while the working time of the resin can be extended by using a thinner.

Standard resin:

- Working time: 6 minutes from the moment the components are combined;

- Actual application time: approx. 4 minutes (after approx. 2 minutes of mixing);

- Repainting: min. after 1 hour, max. after 24 hours;

- Full mechanical resistance:

- for pedestrian traffic: after 4 hours;

- for vehicle traffic: after 12 hours;

- for forklift traffic: after 24 hours;

- Full chemical resistance: 4 days after application of the last coat;

Resin with 2% water added:

- Working time: 3 minutes from the moment the components are combined;

- Actual application time: approx. 1 minute (after approx. 2 minutes of mixing);

- Repainting: min. after 1 hour, max. after 24 hours;

- Full mechanical resistance:

- for pedestrian traffic: after 2 hours;

- for vehicle traffic: after 6 hours;

- for forklift traffic: after 24 hours;

- Full chemical resistance: 3 days after application of the last coat;

Resin with 10% QuickCoat thinner added:

- Working time: 12 minutes from the moment the components are mixed;

- Actual application time: approx. 10 minutes (after approx. 2 minutes of mixing);

- Repainting: min. after 1 hour, max. after 24 hours;

- Full mechanical resistance:

- for foot traffic: after 6 hours;

- for vehicle traffic: after 18 hours;

- for forklift traffic: after 36 hours;

- Full chemical resistance: 5 days after application of the last coat;

Due to the very fast drying time, we recommend that only experienced contractors apply the standard version of the resin and the version diluted with water.

When applying resin with the addition of water or thinner to QuickCoat, when mixing the components, first mix the water/thinner with the product base (component A), then add the hardener (component B).

The version with thinner is only suitable for thin-film applications - it cannot be applied in layers thicker than 150 µm.

If you would like more information, please contact us.

Instructional video:

Instant floor resin - for express repairs - paint for cold stores and freezers QuickCoat 40-10

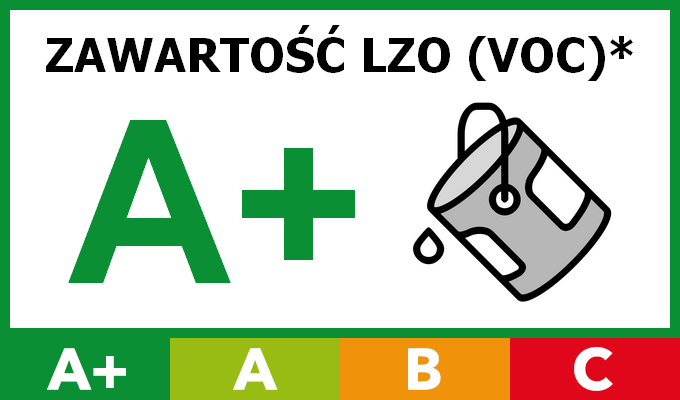

Volatile Organic Compounds:

QuickCoat 40-10 cold storage paint in the standard version

Volatile Organic Compounds (VOC) content - 0 g/l

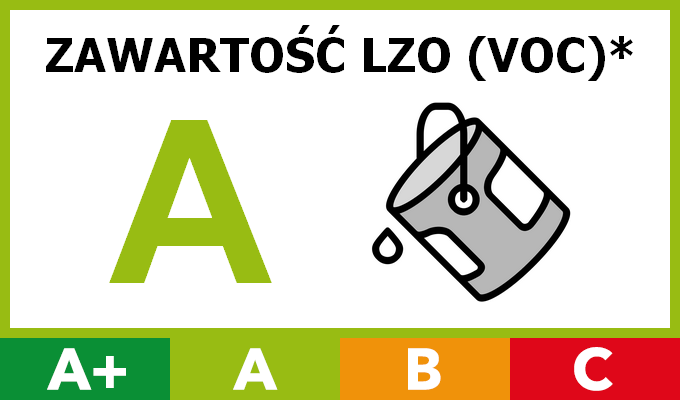

DoPox® 40-10 QuickCoat cold storage paint with 10% QuickCoat thinner added

Volatile Organic Compound (VOC) content - 100 g/l

* Information on the level of vapor emissions (VOC) during application and until the paint is fully cured.

Emission levels from A+ (very low) to C (high).

Additional information on Volatile Organic Compounds.

Documentation:

Datasheets

- Technical Data Sheet – detailed product properties and application method

- Safety Data Sheet – base – chemical, health and safety, and transport information

- Safety Data Sheet – hardener – chemical, health and safety, and transport information

Safety and environmental certificates

- PZH Hygienic Certificate – confirmation of the product’s sanitary safety

- REACH / SVHC / phthalates declaration – statement confirming the absence of harmful substances