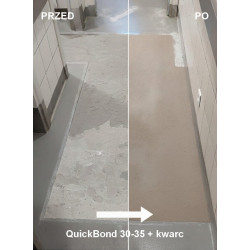

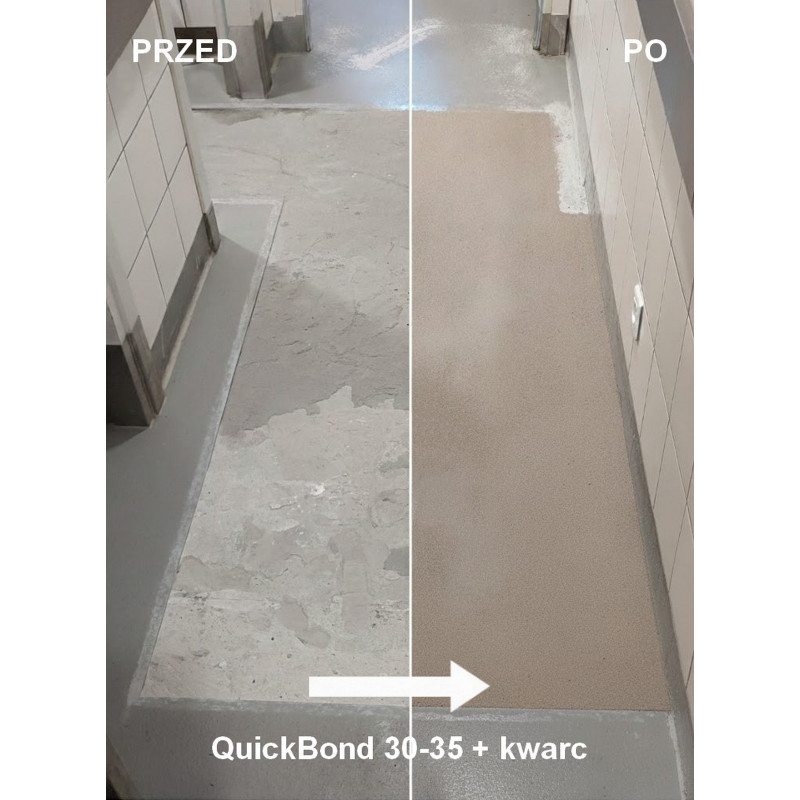

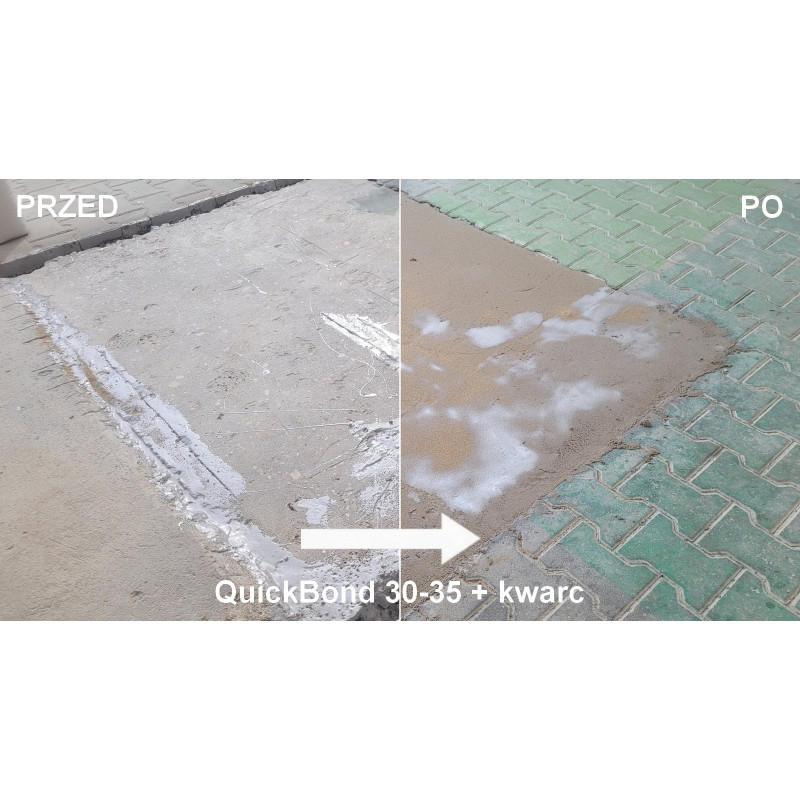

Quick-drying repair mortar - QuickBond 30-35 + quartz

QuickBond 30-35 fast-drying epoxy mortar with quartz sand is a very good solution for repairing floors in industrial and production halls exposed to forklift traffic. The mortar is quick-drying – ready for repainting 2-3 hours after application (at 20°C – check drying times). It can be used on dry and slightly damp substrates, at low temperatures from 5°C.

The fast-drying epoxy mortar Rompox 1505HR with the addition of quartz sand is characterized by high resistance to abrasion and impact. It has very good adhesion to concrete. It is based on a solvent-free resin and does not contain Volatile Organic Compounds (VOC = 0).

For every 1 kg of QuickBond 30-35 fast-drying epoxy resin, 1 to 8 kg of quartz sand can be added. Even at a ratio of 1:8, the mortar is resistant to forklift traffic. By adding 1-2 kg of sand per 1 kg of resin, we obtain a liquid product ideal for filling small gaps. By adding approx. 3 kg of sand per 1 kg of resin, we obtain a semi-liquid, easy-to-spread mortar. By adding 4-8 kg of sand to 1 kg of resin, we obtain a mass resembling masonry mortar, which must be spread and leveled with a trowel.

Consumption: 1.6 kg of mixture (resin + sand) per m² at a thickness of 1 mm

More information about QuickBond 30-35 + quartz quick-drying repair mortar.

Drying times:

The table below shows approximate drying times for sanding primed substrates depending on their temperature.

| Substrate temperature*: | +12°C | +20°C | +30°C |

| Drying time: | 4 - 5 h | 2 - 3 h | 1 - 2 h |

Remarks:

- Temperature determines the curing time of QuickBond 30-35 epoxy resin; lower temperatures prolong the curing time, higher temperatures shorten the curing time.

- The pot life of the mixed material is approximately 10-12 min. (at 20°C). At lower temperatures, the application time is expected to be longer, while at higher temperatures, it is expected to be shorter.

- * Temperature measured inside the substrate; may vary depending on environmental conditions and the amount of primer used.

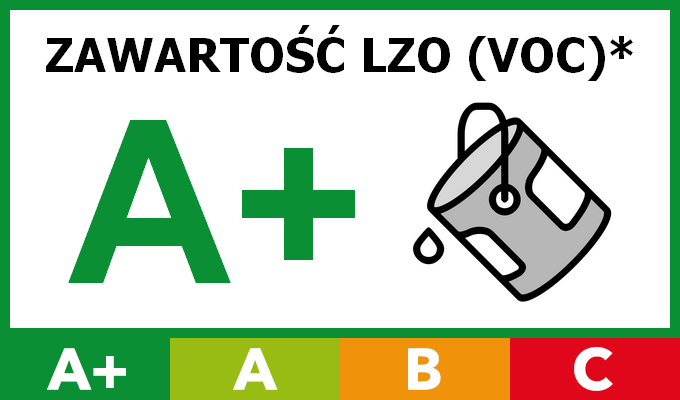

Volatile Organic Compounds:

QuickBond 30-35 + quartz fast-drying epoxy mortar

Volatile Organic Compounds (VOC) content - 0 g/l

* Information on the level of vapor emissions (VOC) during application and until the paint is fully cured.

Emission levels from A+ (very low) to C (high).

Additional information on Volatile Organic Compounds.

Documentation:

Datasheets

- Technical Data Sheet - detailed product properties and application method

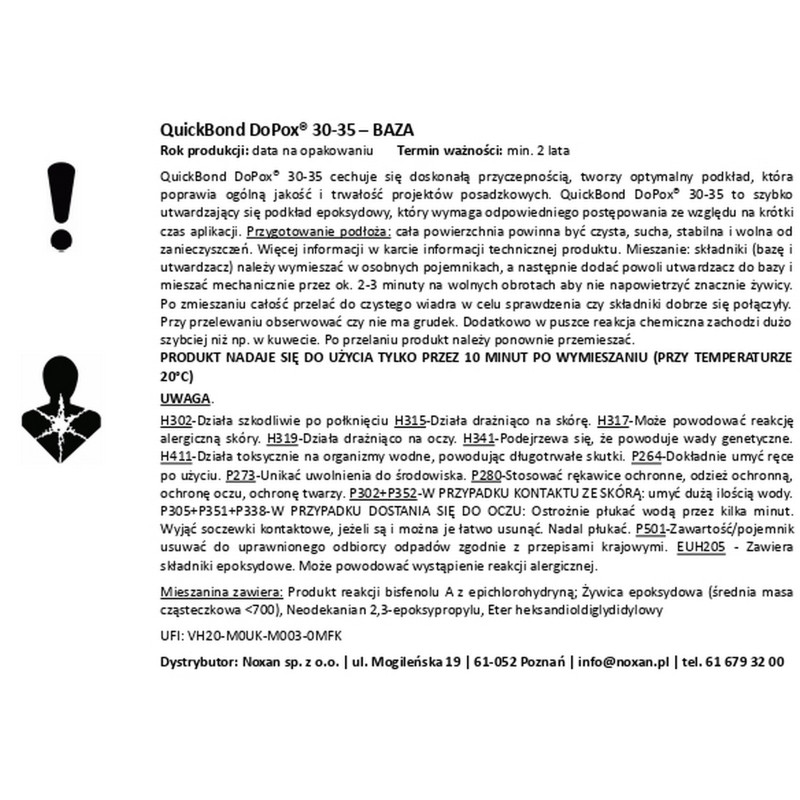

- Safety Data Sheet - base - chemical, health and safety, and transport information

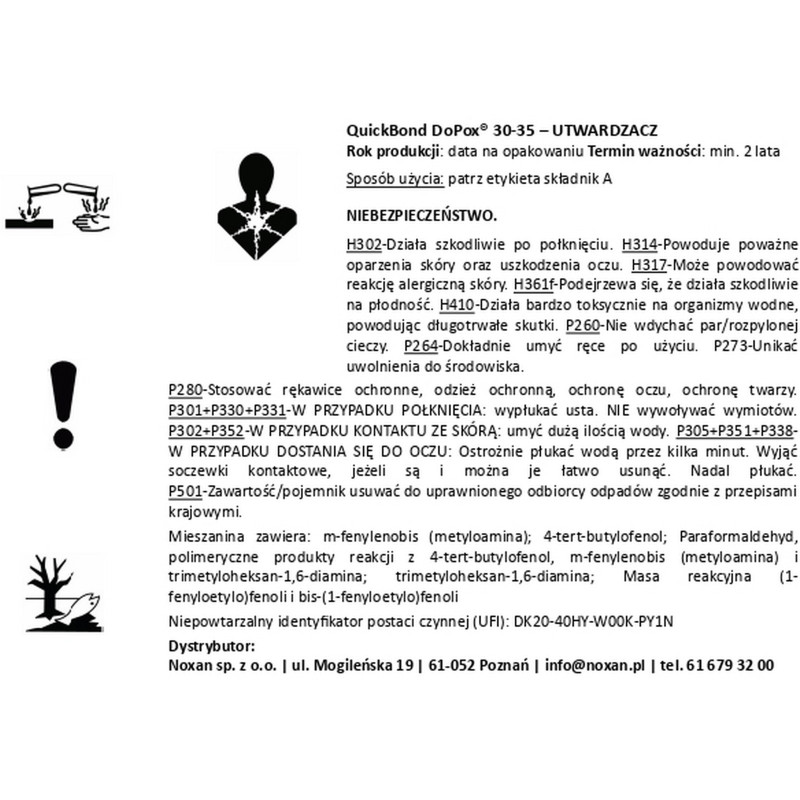

- Safety Data Sheet - hardener - chemical, health and safety, and transport information

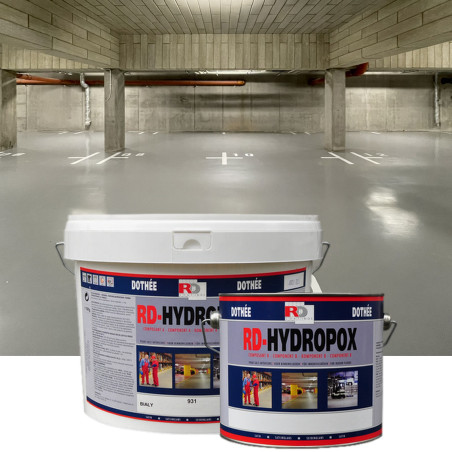

Customers who bought this product also bought:

Epoxy primer/impregnant - HP Primer W221

Quick-drying polyurea paint - QuickCoat 40-10

Paint tray

Expansion cord

Concrete repair mortar - Cement Filler

Epoxy primer for dry concrete - Dominator DoPox® 30-34

Concrete repair resin - Rompox 1505 + quartz

-

gray light

zł123.00 brutto

zł100.00 zł netto

zł123.00 brutto za 1 kg

zł123.00 brutto

zł100.00 zł netto

zł123.00 brutto za 1 kg