- On sale!

Preparation for rust - Rust modifier Q607

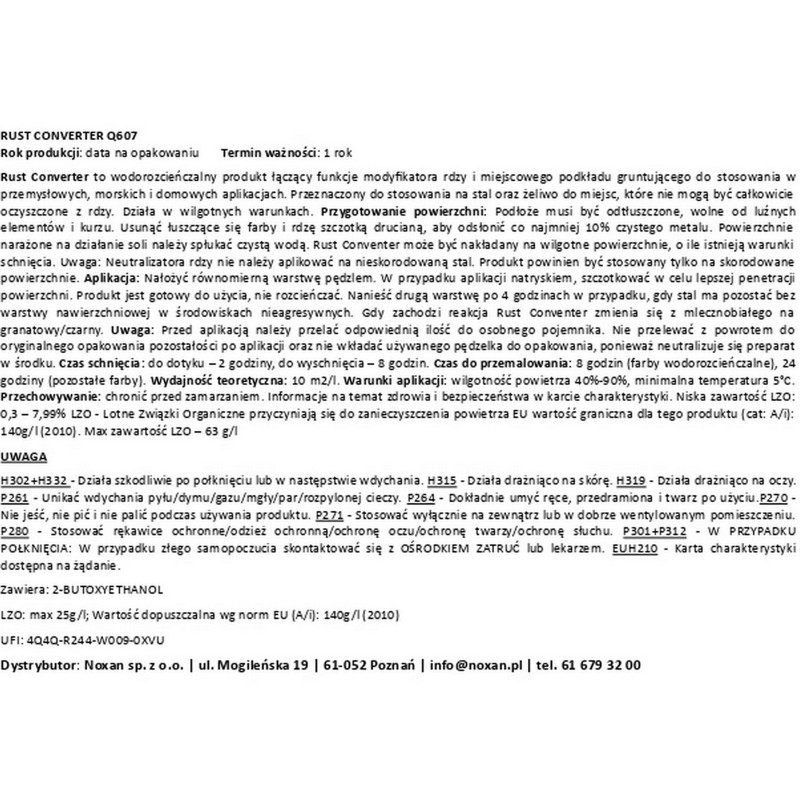

Rust treatment Q607 Rust Modifier is a special agent that stops the rusting process and prevents rust from forming on steel and iron surfaces, even in humid conditions.

Thanks to its properties, Q607 Rust Remover transforms rust into a stable form, allowing for safe repainting of the surface.

Q607 Rust Remover is extremely resistant to rust and prevents the rusting process from recurring. It is particularly recommended for use on surfaces that cannot be completely cleaned of rust.

Q607 rust remover key properties:

- stops the rusting process

- prevents new rust from forming

- can be applied in humid conditions in industrial and marine environments

- for use on steel and cast iron surfaces

- allows the application of Q113 two-component epoxy anti-corrosion primer, P201 anti-corrosion primer, CombiColor metal paint, and other anti-corrosion primers on substrates that cannot be thoroughly cleaned of rust

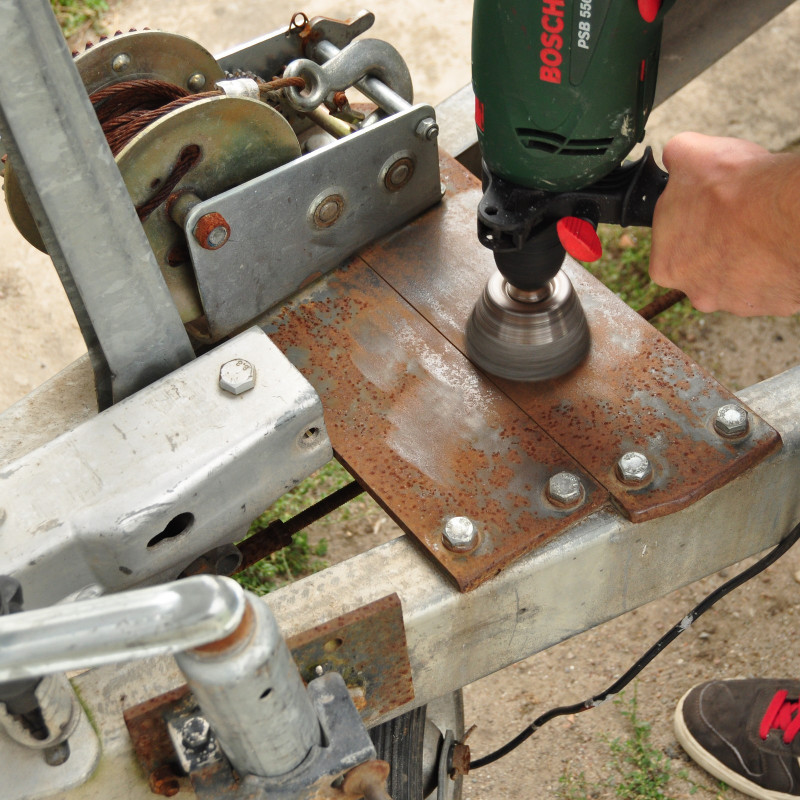

- application by brush, roller, or air spray

Coverage: 10 m²/l

More information about the rust treatment product Q607 Rust Modifier.

New 0.25 l packaging

Rust Converter Q607 is designed for cleaning surfaces and components made of steel and cast iron. The product can be used in humid conditions, making it ideal for industrial and marine environments for protecting ships, metal boats, yachts, etc. Proven and in use in North Sea oil refineries since 1984.

Instructional videos

How does a rust remover work?

How to prepare rusted steel for painting?

Documentation:

Datasheets

- Technical Data Sheet – detailed product properties and application method

- Safety Data Sheet – chemical, health and safety, and transport information

Frequently asked questions:

1. What is Rust Converter Q607?

Rust Converter Q607 is a chemical preparation that reacts with rust (iron oxide), transforming it into a stable, inert compound that can be painted over. It converts rust into a black, protective coating, preventing further corrosion.

2. How does a rust converter work?

Rust converters typically contain tannic acid and an organic polymer. The tannic acid reacts with the iron oxide (rust) to form a stable iron tannate, and the polymer forms a protective layer. This process prevents further rusting and prepares the surface for painting.

3. When should Q607 Rust Modifier be used?

- Light to moderate rust: Ideal for surfaces with light to moderate rust.

- Preventative maintenance: Can be used on surfaces prone to corrosion to prevent it from forming.

- Preparation for painting: Prepares rusted surfaces for painting, improving paint adhesion and coating durability.

4. How to use Q607 rust remover?

- Surface preparation: Remove loose rust, paint, dirt, and grease with a wire brush, sandpaper, or degreaser.

- Application: Apply the modifier with a brush, roller, or spray, covering the surface evenly.

- Drying: Allow to dry according to the manufacturer's instructions – usually 8 to 24 hours.

- Painting: Once the modifier is dry and cured, the surface can be painted.

5. Can Q607 Rust Modifier be used on heavily corroded surfaces?

The modifier works best on surfaces with light to moderate rust. In case of heavy corrosion, remove as much loose rust as possible first. In severe cases, mechanical removal of rust may be necessary.

6. How long does the rust modifier take to work?

- Touch dry: 4 hours.

- Fully dry: 8 hours.

- Time to paint: 8 hours for water-based paints, 24 hours for other paints.

7. Can Q607 Rust Modifier be used on painted surfaces?

The modifier should be applied directly to rusted metal. It is not effective on painted surfaces. If it has been applied to painted surfaces, it must be removed before applying new paint coatings.

8. Is a rust modifier the same as a rust remover?

No. The modifier and rust remover have different functions. Rust remover dissolves and removes rust from metal surfaces, while the modifier chemically transforms rust into a stable compound that can be painted.

9. Do you need to paint the surface after applying a rust modifier?

Yes, it is strongly recommended to paint the surface after applying the modifier. Although it creates a stable base, its protective layer is not as durable as a topcoat. Painting provides additional protection against moisture and corrosion.

10. Can rust converters be used on all types of metal?

Rust converters are usually designed for ferrous metals (iron and steel). They are not suitable for non-ferrous metals such as aluminum, copper, or stainless steel (unless they are first washed with a pickling solution such as Mordant Solution).