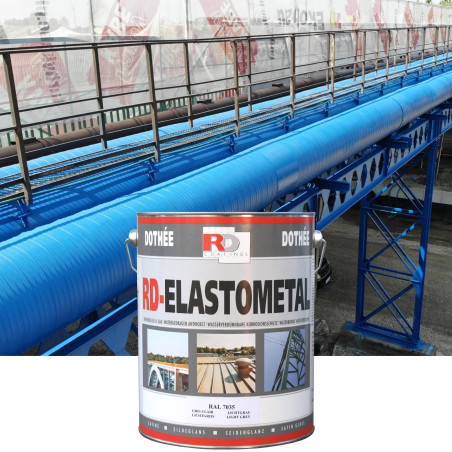

Paint for steel structures, anti-corrosive, fast-drying - Monoguard

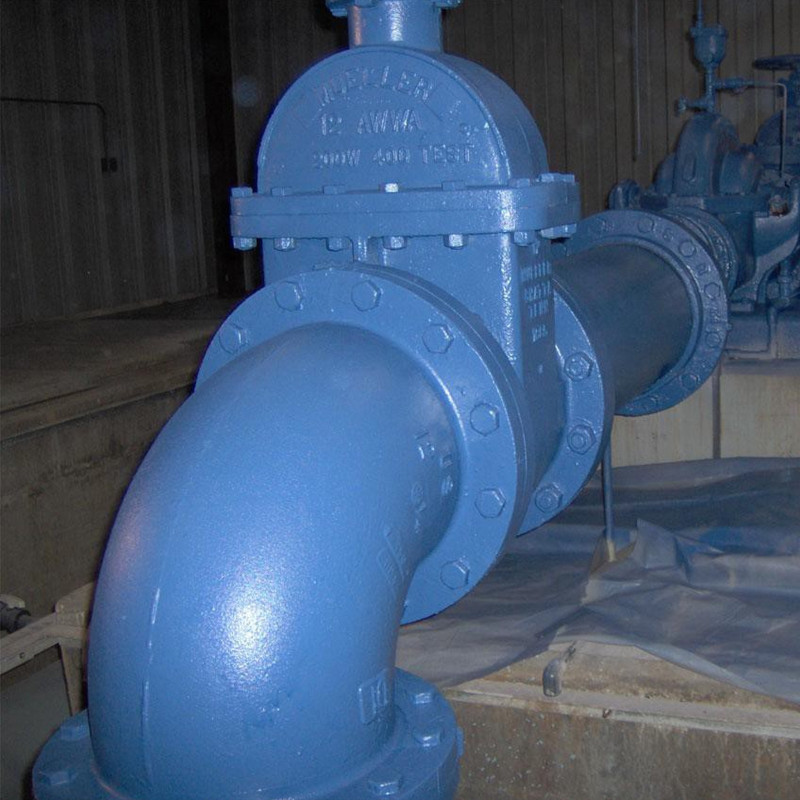

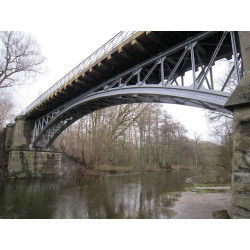

Monoguard is a highly durable, water-based, quick-drying 2-in-1 anti-corrosion paint for direct application on rust, steel, zinc, and more, even in harsh industrial conditions.

Monoguard steel structure paint is based on a new generation of acrylic resins and special anti-corrosive substances. It creates a highly resistant protection for steel against temperature changes and external conditions. In addition, the paint is flexible, so it does not crack or peel. Thanks to its excellent UV resistance, the paint does not yellow and the colors fade very slowly.

Monoguard steel structure paint has excellent adhesion to many substrates, including:

- steel and cast iron (including rusted),

- galvanized steel,

- stainless steel.

Monoguard is ideal for general renovations as well as minor repair work. Before application, it requires only minimal substrate preparation (see application notes).

More information about Monoguard, a fast-drying, anti-corrosive paint for steel structures.

More colors - Monoguard - color palette from the mixer.

PROVEN EFFECTIVENESS

Monoguard can be used in harsh industrial and marine environments (C5). Its anti-corrosion effectiveness over a very long period (vH > 25 years) has been proven in tests conducted by the independent COT laboratory.

LONG-TERM PROTECTION

Monoguard anti-corrosion paint provides long-lasting (> 25 years) protection. Thanks to its very high adhesion and resistance to external conditions, it does not peel or flake off over time.

EXCELLENT ADHESION

Outstanding adhesion to various metals guarantees the effectiveness and versatility of the product. Thanks to its excellent adhesion, Monoguard anti-corrosion paint can be used both as a primer and a topcoat.

Key features:

Durable corrosion protection - Certified in C5 environment

- 20 years of rust protection in a C5 environment,

effectiveness of rust protection for heavy industrial and marine C5 environments over a long (H) period (15-25 years) confirmed by ISO 12944-6 certification and numerous references - High resistance to outdoor conditions and impact,

including variable weather and temperature, and UV radiation

Outstanding adhesion - Effectiveness and versatility

- up to 17 MPa / 2500 PSI when

tested for pull-off in accordance with ISO 4624 (a result well above the 7 MPa / 1000 PSI values regularly required by many industrial specifications) - Ideal anti-corrosion paint for:

- steel (black, galvanized, and stainless),

- old well-adhering paint coatings

- and many other substrates.

Quick application - 1 day of work for 20 years of protection

- no sanding required,

the substrate only needs to be washed with a pressure washer (St2) - easy and safe to use, water-based,

single-component product - has high flowability, spreads

perfectly and leaves no streaks - dries quickly,

touch dry in 1-2 hours, recoatable in 1-4 hours - 2-in-1, primer

and topcoat paint with high covering power

Safe for people and the environment - low VOC content and PZH certification

- low VOC content: < 55 g/l,

the product meets the requirements of LEED 2009 and LEED v4 in terms of Volatile Organic Compound content - PZH certificate

confirming that Monoguard can be used as anti-corrosion protection for structures, cladding, and elements in residential, public, and industrial buildings, including in the food industry (without direct contact with food) - does not contain copper and zinc,

copper 0%, zinc above 0.1% by weight - does not contain isocyanates, does not contain Bisphenol A (BPA)

Tests and certificates:

The anti-corrosion properties of Monoguard paint are confirmed by tests and certificates:

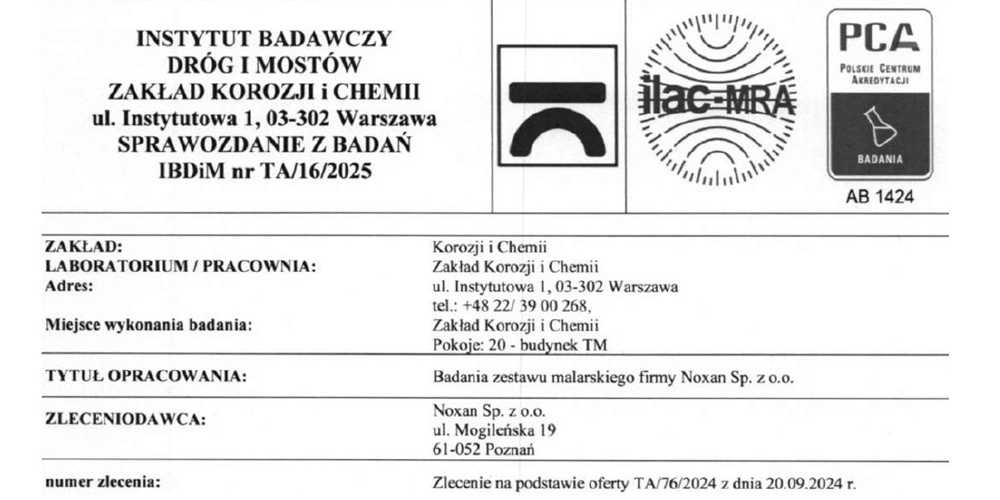

The Road and Bridge Research Institute is the country's leading scientific and research institution dealing with transport infrastructure issues. The Institute's activities are focused on the development of science and the practical application of research results.

The Dutch research center COT (Centre for Research and Technical Advice). The COT laboratory performs chemical analyses, tests the physical and technical properties of coatings, and conducts climate tests.

M2LAB BV is an independent testing laboratory specializing in materials inspection and a member of NVVT (Association of Paint Technicians) and NRK (Association of the Plastics and Rubber Industry).

Systems:

| Protection period: | Environment: | Wet film thickness: | Dry film thickness: | Total consumption: | Number of layers: | Yield: | Cost per m² from: |

|---|---|---|---|---|---|---|---|

| Long (H > 15 years) |

C5 heavy industrial and marine |

500 µm | 215 µm | 0.5 l/m2 | 3 | 6 m2/l | check the cost of the system |

| C4 industrial and coastal |

350 µm | 150 µm | 0.35 l/m2 | 2 | 5.5 m2/l | check the cost of the system | |

| C3 urban and industrial light |

255 µm | 110 µm | 0.25 l/m2 | 2 | 8 m2/l | check the cost of the system |

Yield:

- hydrodynamic spraying - from 4 m²/l per coat

- brush - from 7 m2/l per coat

- roller - from 10 m2/l per coat

Volatile Organic Compounds:

Monoguard steel structure paint

Volatile Organic Compound (VOC) content

- Manufacturer's colors - < 45 g/l

- Colors from the mixer - < 55 g/l

* Information on the level of vapor emissions (VOC) during application and until the paint is fully cured.

Emission levels from A+ (very low) to C (high).

Additional information on Volatile Organic Compounds.

Instructional videos

We invite you to watch instructional videos on the application of Monoguard paint

Corrosion protection for clean steel

Corrosion protection for corroded steel

Corrosion protection for zinc

Documentation:

Datasheets

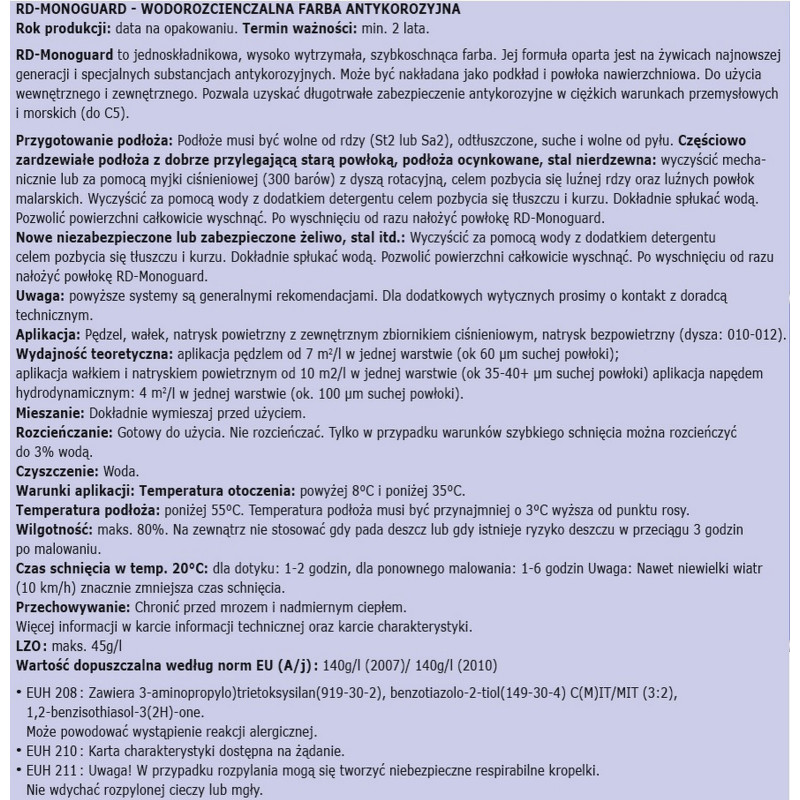

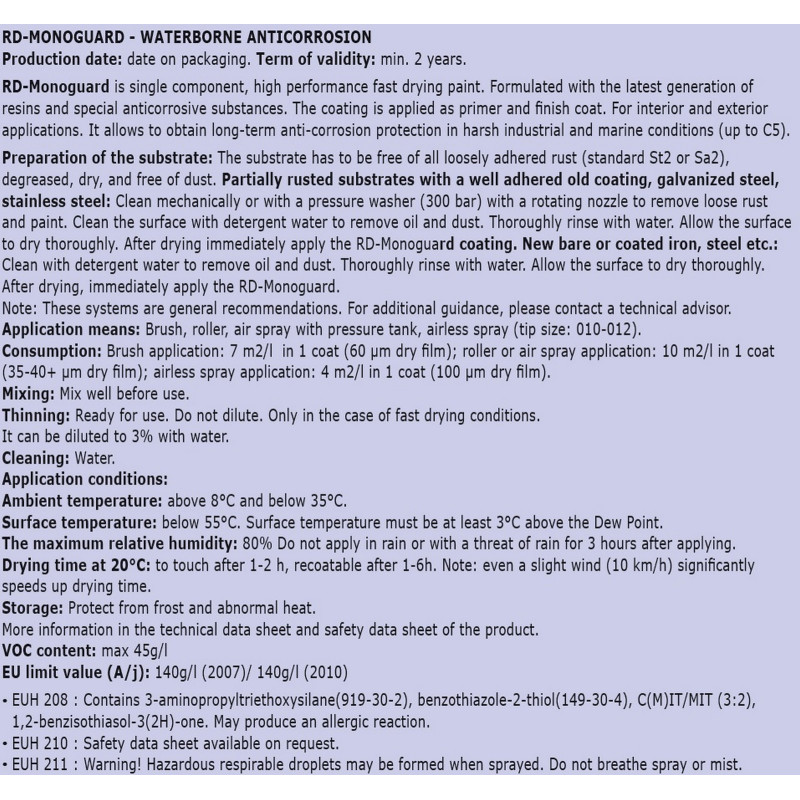

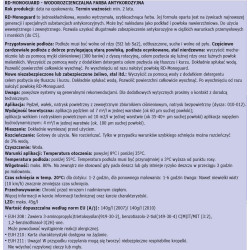

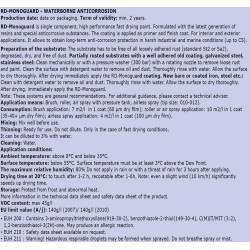

- Technical Datasheet - PL version / ENG - detailed product properties and application method

- Safety Data Sheet - PL version / ENG - chemical, health and safety, and transport information

Application instructions

- Application instructions - a practical step-by-step application guide

Declarations

- Declaration of Performance (DoP) - for the Elastometal + Monoguard system in a C5 High environment

- Declaration of performance parameters (according to ISO/ASTM) - for Monoguard

Certificates – anticorrosion performance

- National Technical Assessment (KOT) - for the Elastometal + Monoguard system in a C5 High environment

- Test results – IBDiM Corrosion and Chemistry Department - for the Elastometal + Monoguard system in a C5 High environment

- Test results – M2LAB laboratory - for the Monoguard system in a C5 Very High environment

- ISO 12944-6 certificate – C5 High - for the Monoguard system in a C5 High environment

- Test results – COT laboratory - for the Monoguard system in a C5 High environment

- ISO 12944-6 certificate – C5 High - for the Monoguard + Hydrograff HP system in a C5 High environment

- Test results – COT laboratory - for the Monoguard + Hydrograff HP system in a C5 High environment

- ISO 12944-6 certificate – C5 High - for the Elastometal + Monoguard system in a C5 High environment

- Test results – COT laboratory - for the Elastometal + Monoguard system in a C5 High environment

Certificates – safety and environment

- PZH hygienic certificate - confirmation of the product’s sanitary safety

- Environmental Product Declaration (EPD) - life-cycle assessment and environmental impact

- LEED v4 compliance certificate for VOC emissions - tests confirming low VOC emissions after 28 days

- LEED, Green Seal - confirmation of low VOC (volatile organic compounds) content in the product

- Red List, Living Building Challenge - manufacturer declaration regarding the absence of Red List substances

- Declaration of zero copper content and minimal zinc content - copper: 0%; zinc < 0.1% by weight

Certificates – light-reflective properties

- Energy performance - for Monoguard in white - energy reflectance measurement and SRI calculation

Additional materials

- Information brochure - basic information and product benefits

- Reference list - sample projects and applications

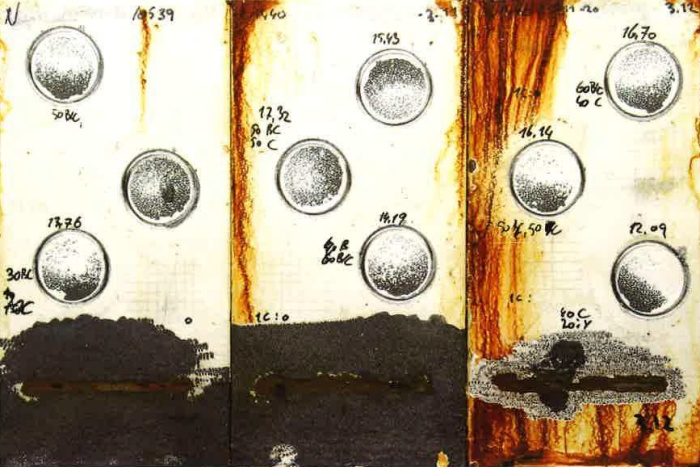

Salt spray test – resistance to rust development:

After 1440 h of salt spray testing, the Monoguard anticorrosion paint remains intact. Even around the scribe, rust does not develop under the coating.

By applying 215 micrometres of Monoguard anticorrosion paint (dry film thickness), we obtain one of the most durable anticorrosion systems. The expected durability of the system is from 15 to 25 years under industrial conditions.

Salt spray test 1440 h - Monoguard

215 µm coating

Monoguard adhesion to ferrous and non-ferrous metals:

Adhesion to ferrous metals:

Monoguard steel structure paint has excellent adhesion to ferrous metals - steel and cast iron (see COT tests for adhesion to steel - p. 4 and appendix p. 1 - 4).

Monoguard's adhesion increases over time. Weeks and months after application, the innovative components inside the coating continue to increase the bond, reaching up to 17 MPa / 2500 PSI when performing a pull-off test in accordance with ISO 4624 (substrate pull-off strength test). These values significantly exceed the 7 MPa / 1000 psi regularly required by many industry specifications.

Monoguard's excellent adhesion also actively contributes to protecting steel from corrosion. Because the coating adheres so well to the surface, it is more difficult for rust to begin its damaging expansion. The bond works so well that rust simply does not have enough strength to push the coating away and come into contact with the bare metal surface to which Monoguard has literally bonded itself.

This is also a big advantage in the event of local damage to the coating, as rust will not be able to spread easily.

Steel plates 3.9, 3.11, and 3.12 protected with Monoguard anti-corrosion paint after 1,440 hours of testing in neutral salt spray

Adhesion to non-ferrous metals:

For non-ferrous metals, Monoguard steel structure paint has excellent adhesion to galvanized steel, stainless steel, old patinated, and oxidized copper. For other metals, such as new copper or aluminum, special substrate preparation or the use of Multiprim paint for aluminum and smooth substrates may be required to achieve the best adhesion.

Detailed information is provided in the tables below.

Legend:

- GT is the result of testing using the Cross Cut method;

- The best adhesion is GT0. The following numbers (1, 2, 3) indicate poorer adhesion (the higher the number, the poorer the adhesion);

- For more information, see here.

| ALUMINUM | ||

|---|---|---|

| Product | Substrate preparation | Adhesion |

| Monoguard | water + detergent | poor (adhesion is poor if we only clean and wash the substrate) |

| diluted sulfuric acid + rinse with water | GT1 | |

| Multiprim | water + detergent | GT0 |

| diluted sulfuric acid + rinse with water | GT0 | |

| Conclusion: Multiprim gives much better results than Monoguard on aluminum. No acid preparation of the substrate is required for Multiprim. Acid preparation of the substrate is required for Monoguard. For projects where aluminum is not exposed to mechanical stress, the adhesion of Monoguard to properly prepared aluminum may be sufficient. However, before applying it, we recommend testing it on a smaller area to confirm that Monoguard adheres well. |

||

| COPPER - NEW, IN GOOD CONDITION | ||

|---|---|---|

| Product | Substrate preparation | Adhesion |

| Monoguard | water + detergent | GT2 |

| 10% hydrochloric acid + rinse with water | GT0 | |

| Multiprim | water + detergent | GT2 |

| 10% hydrochloric acid + rinse with water | GT0 | |

| Conclusion: Monoguard and Multiprim give the same result on new copper. For best adhesion, it is useful to prepare the substrate with acid. During testing, cleaning with a 10% acid solution did not change the appearance of new copper. However, we obviously recommend conducting a test cleaning on a smaller area to confirm that the aesthetic effect will be satisfactory. |

||

| COPPER - OLD PATINATED, OXIDIZED | ||

|---|---|---|

| Product | Substrate preparation | Adhesion |

| Monoguard | water + detergent | GT0 |

| Multiprim | water + detergent | GT0 |

| Conclusion: Monoguard and Multiprim give the same result on galvanized steel. Acidic substrate preparation is not required. We recommend using Monoguard paint because it has better anti-corrosion properties. | ||