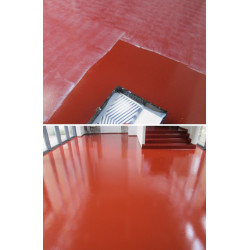

Polyurethane surface - Hydrograff HP

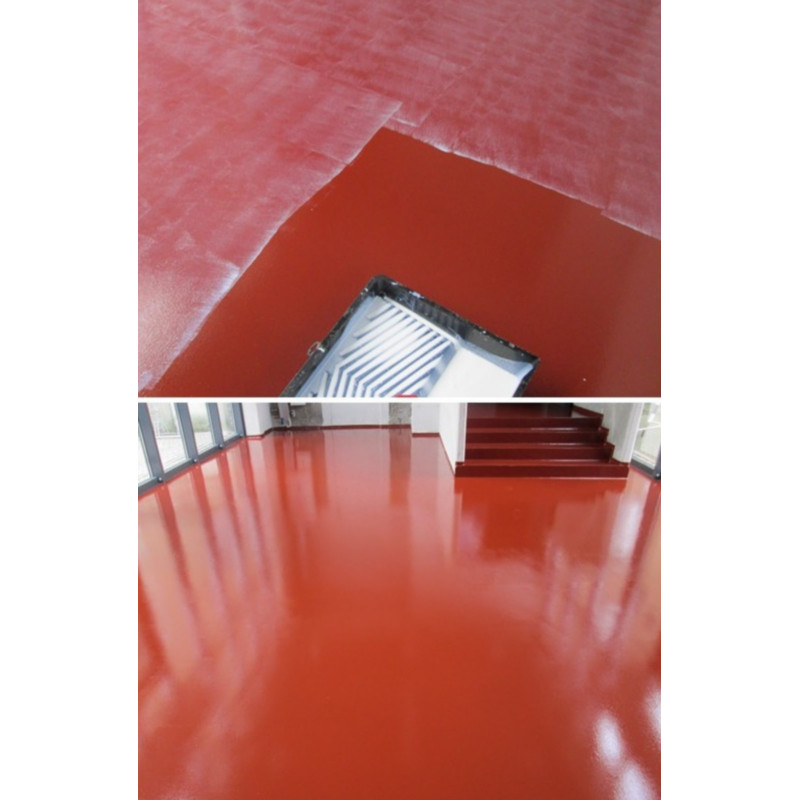

Hydrograff HP is a modern, water-based, two-component polyurethane coating with low VOC content. The coating is highly resistant to mechanical and chemical damage, surpassing many solvent-based systems.

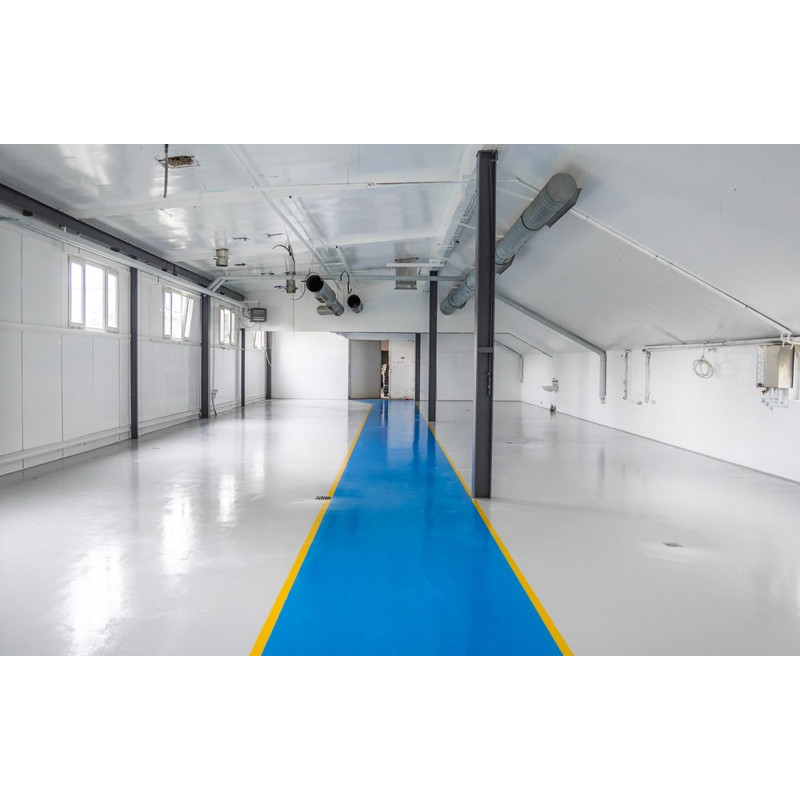

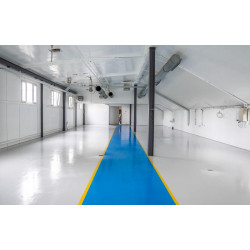

It ensures excellent appearance and maintains the color and gloss of the floor for a very long period of use. It is ideal for use in warehouses with medium forklift traffic, etc.

The Hydrograff HP polyurethane surface has good chemical resistance to cleaning agents, many oils (e.g., engine oil, hydraulic oil), solvents, as well as alkalis and acids (e.g., 10% sulfuric acid, 10% lactic acid). For complete information, see the chemical resistance chart.

Available versions:

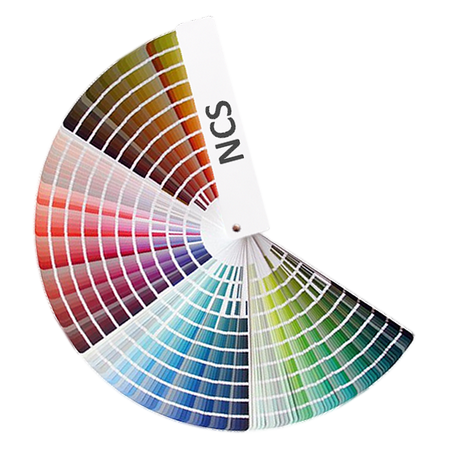

- gloss, satin - colorless and all colors

- matte - colorless and selected pastel colors (mixed on an A base - check).

Coverage: 7-10 m²/l

More information about Hydrograff HP polyurethane coating.

More colors of Hydrograff HP polyurethane coating.

Key features:

Product characteristics

- two-component polyurethane floor (2K),

- excellent adhesion to many substrates.

Resistance

- very high mechanical resistance,

resistant to forklift traffic - high chemical resistance,

resistant to chemical cleaning agents, many oils, solvents, acids, and alkalis - check the chemical resistance chart, - flexibility and impact resistance,

- resistance to temperatures of 80°C.

Aesthetics

- unmatched color and gloss retention,

ideal for finishing epoxy coatings - also as a colorless varnish, - available in gloss, satin, and matte finishes,

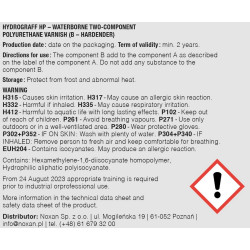

- available in 1000+ colors from the RAL and NCS color charts.

Application and safety

- suitable for covering floors and walls,

- can be applied directly to concrete, epoxy floors, wood, walls, and tiles,

etc. (see systems), - flooring suitable for the food industry, PZH hygiene

certificate and Gent certificate, - water-soluble,

does not emit unpleasant odors during application, - very low VOC content - 20 g/l,

- for best results, we recommend using a 5-8 mm polyurethane paint roller.

More colors:

Instructional videos:

Below are some sample videos showing Hydrograff HP polyurethane coating used as a finish.

Renovation of resin flooring - step-by-step guide

Resin floor - white, polyurethane - for offices and exhibition halls

Application of polyurethane varnish in a warehouse

White resin stairs

Transparent resin on a concrete floor

Resin flooring in a garage

Polyurethane flooring - spray application

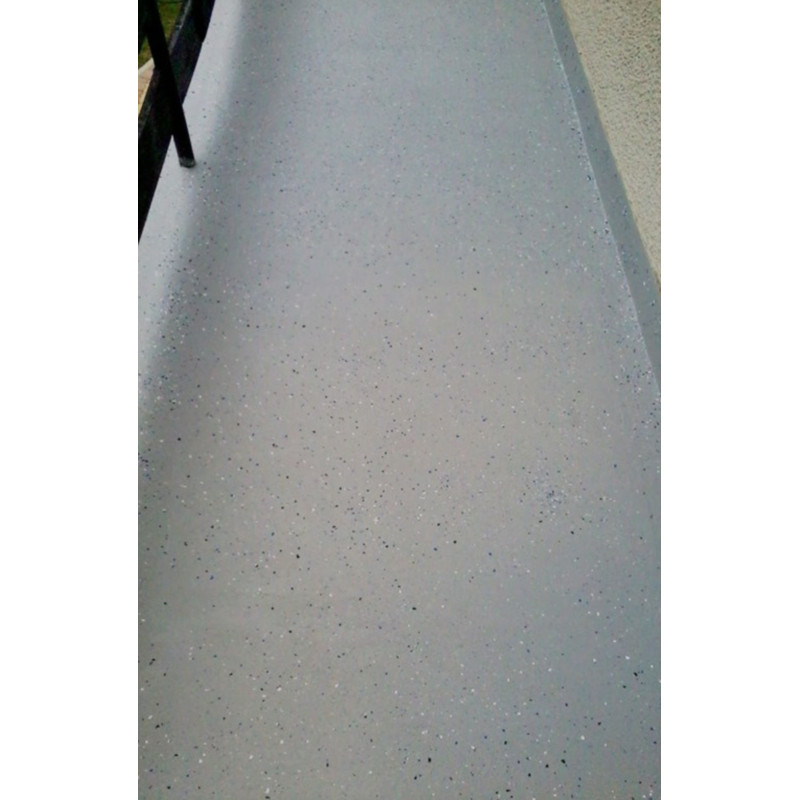

Hydrograff HP polyurethane surface with anti-slip additive:

The slip properties of Hydrograff HP are similar to those of floor tiles. For indoor floors, which are usually dry, it is sufficient to use Hydrograff HP without anti-slip additive.

However, for outdoor floors and indoor floors that are exposed to frequent spills (water, oil, etc.) , we recommend adding NS 200 anti-slip additive when applying the first coat of Hydrograff HP (or sprinkling it on the first wet layer of Hydrograff HP - see How to apply anti-slip additives). Then cover the entire surface with a second coat of Hydrograff HP.

System: HeavyBond 30-33 + Hydrograff HP + NS 200 anti-slip additive + Hydrograff HP has been tested for slip resistance in accordance with PN-EN 13036-4 and has obtained a pendulum roughness index PTV: in dry conditions 78; in wet conditions 70; R12.

NS 200

anti-slip additive

Additional comments:

- Pay attention to the substrate. Depending on the smoothness and absorbency of the substrate, the final finish may vary.

- Please note that the anti-slip additive makes the floor finish rougher and more difficult to clean.

- Concrete outdoors is generally exposed to weather conditions (rain, UV radiation, etc.) and groundwater seepage. This means that moisture can remain in the substrate almost all the time. Therefore, in outdoor systems, we use HeavyBond 30-33 primer, which can be applied to fresh and damp concrete, including concrete exposed to capillary rise.

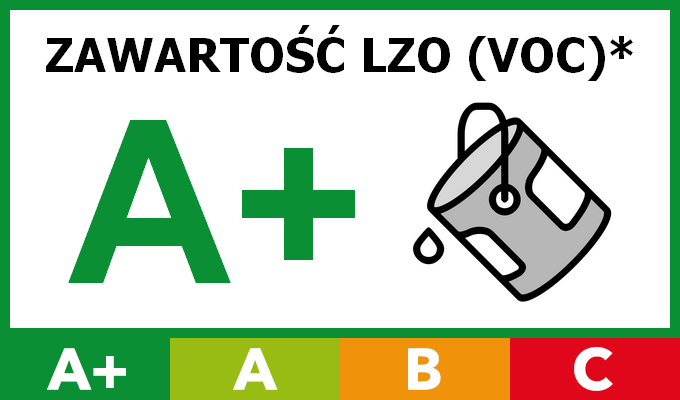

Volatile Organic Compounds:

Hydrograff HP polyurethane surface

Volatile Organic Compounds (VOC) content - 20 g/l

* Information on the level of vapor emissions (VOC) during application and until the paint is fully cured.

Emission levels from A+ (very low) to C (high).

Additional information on Volatile Organic Compounds.

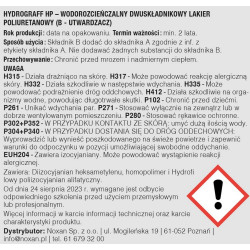

Documentation:

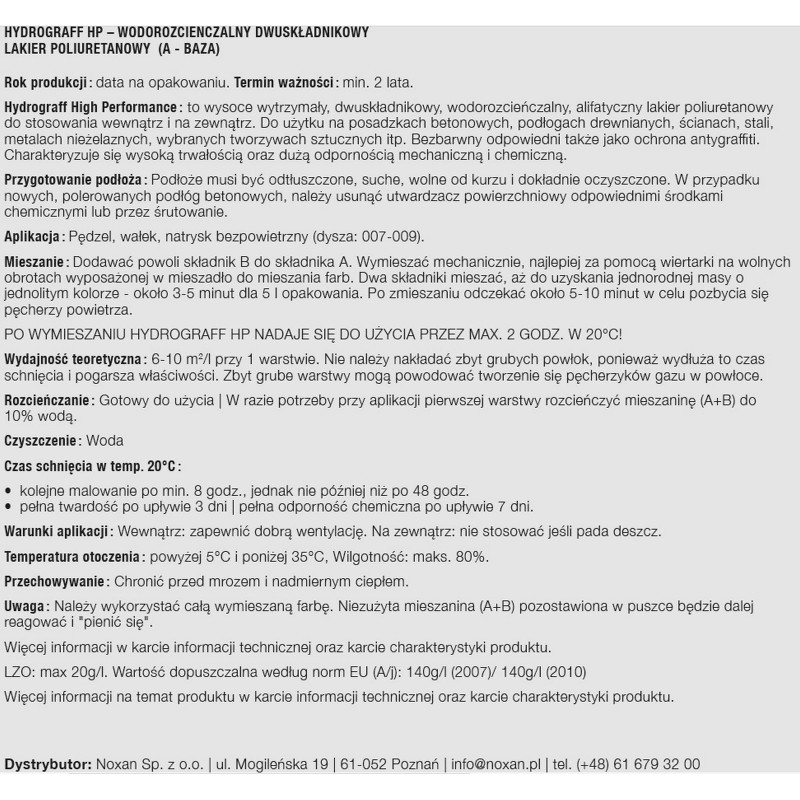

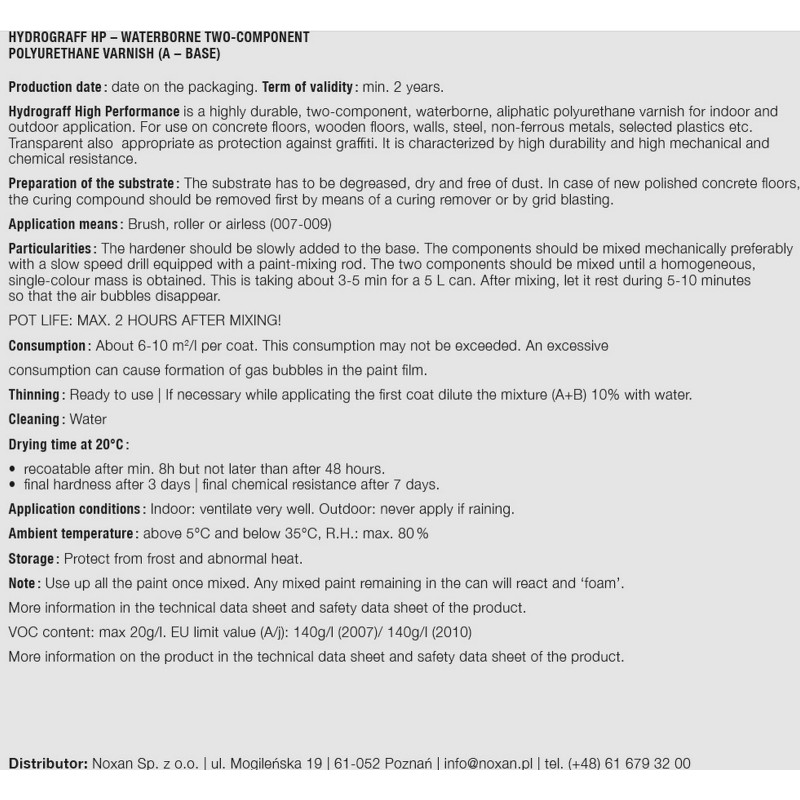

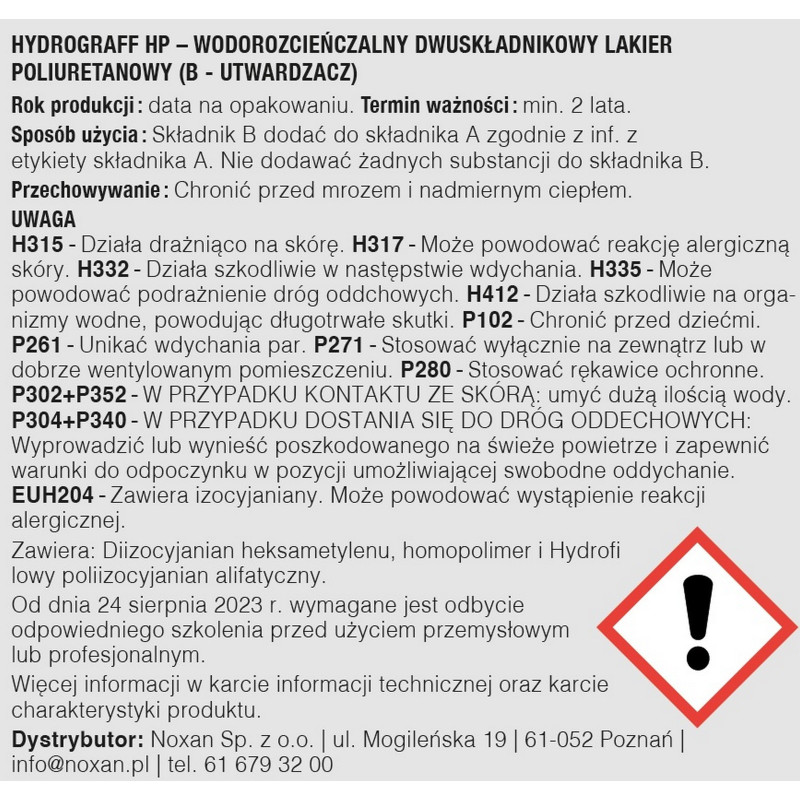

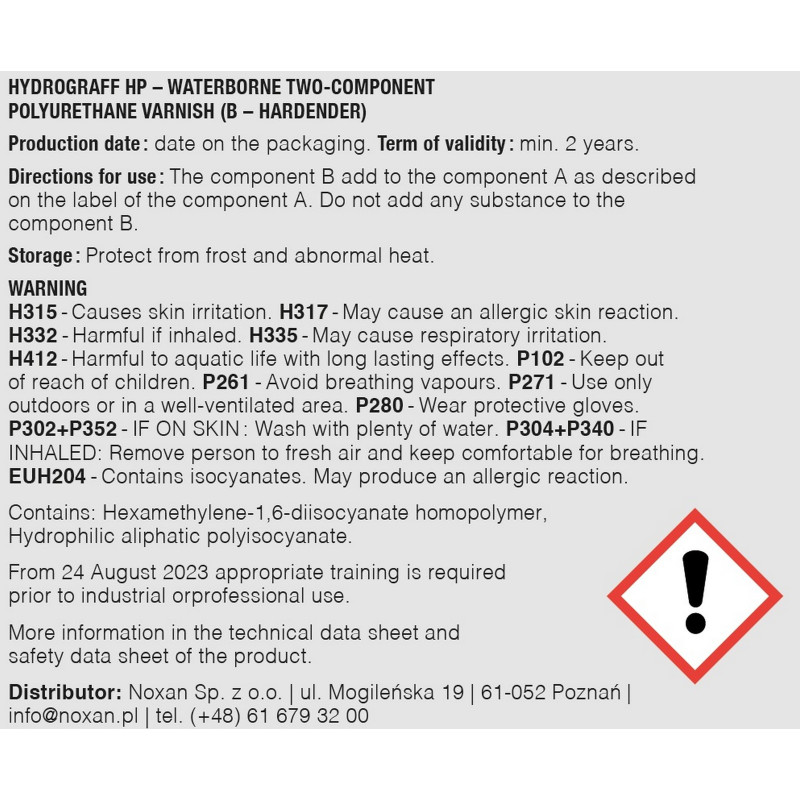

Datasheets

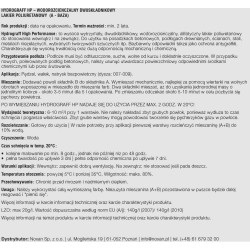

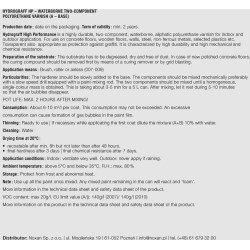

- Technical Data Sheet – detailed product properties and application method

- Safety Data Sheet – base – chemical, health and safety, and transport information

- Safety Data Sheet – hardener – chemical, health and safety, and transport information

Application instructions

- Hydrograff HP – Application instructions – practical, step-by-step application guide

Declarations

Chemical and mechanical resistance

- Chemical resistance data sheet – results after exposure to selected substances

- Abrasion resistance test – Taber Abraser, ASTM D4060: CS-10 wheels, 1000 g load, 1000 cycles; weight loss: 0.060–0.067 g per 1000 cycles (60–67 mg)

Safety and environmental certificates

- PZH hygienic certificate – confirming that Hydrograff HP may be used for: protection of floors and walls in workshops, garages, production halls, food production areas (without direct contact with food), public utility buildings, and residential premises

- Ghent University certificate – confirming compliance with limits set out in European Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food

- LEED v4 VOC emissions compliance certificate – test results confirming low VOC emissions after 28 days

- LEED, Green Seal – confirmation of low volatile organic compound (VOC) content

- Slip resistance test – measurements carried out using a certified and regularly calibrated measuring device, compliant with PN-EN 13136-4

- Red List, Living Building Challenge – manufacturer’s declaration confirming the absence of Red List substances

Notes on capacity:

Why does the can say that there is only 0.99 l, 0.97 l, or 0.93 l of paint?

The total volume of paint consists of the volume of the base and the volume of the pigment.

- The base volume for a 1 l package is as follows: base A 0.99 l, base B 0.97 l, base C 0.93 l.

- The pigment volume for a 1 l package:

- for light colors (base A and B), approx. 1-5% of pigment is added,

- for dark colors (base C), approx. 5-10% pigment is added.

The total volume depends on the color, but is very close to 1 l.

The exact volume of a 1 l package, depending on the color, is presented in the table on the right/below.

The volume of 2.5 l and 5 l packages differs analogously.