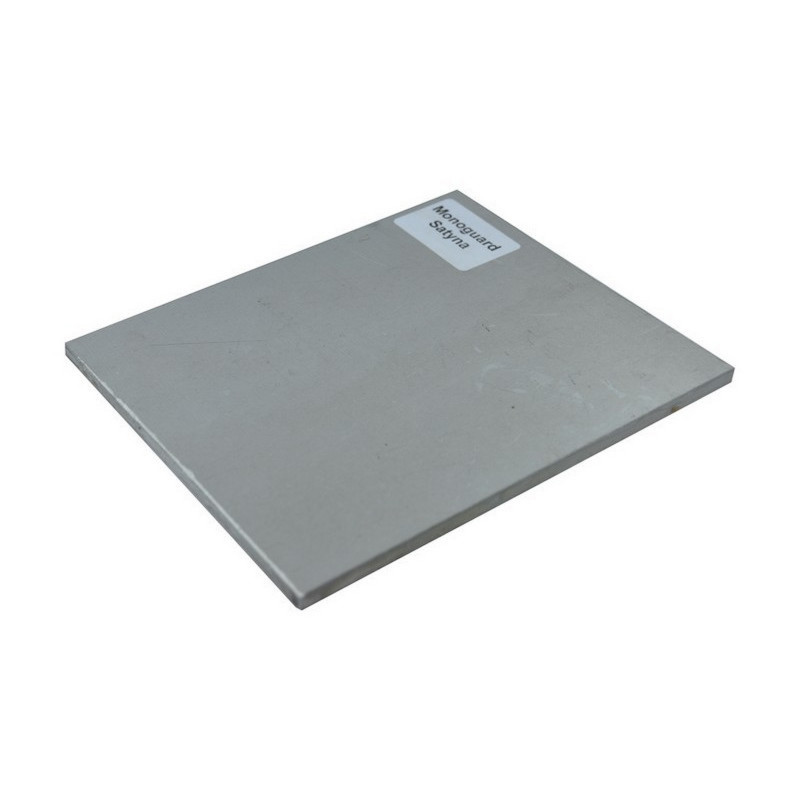

Anti-corrosion varnish - Monoguard Clear

Monoguard Clear is a highly durable, water-based, colorless 2-in-1 anti-corrosion varnish that combines the properties of a primer and a topcoat.

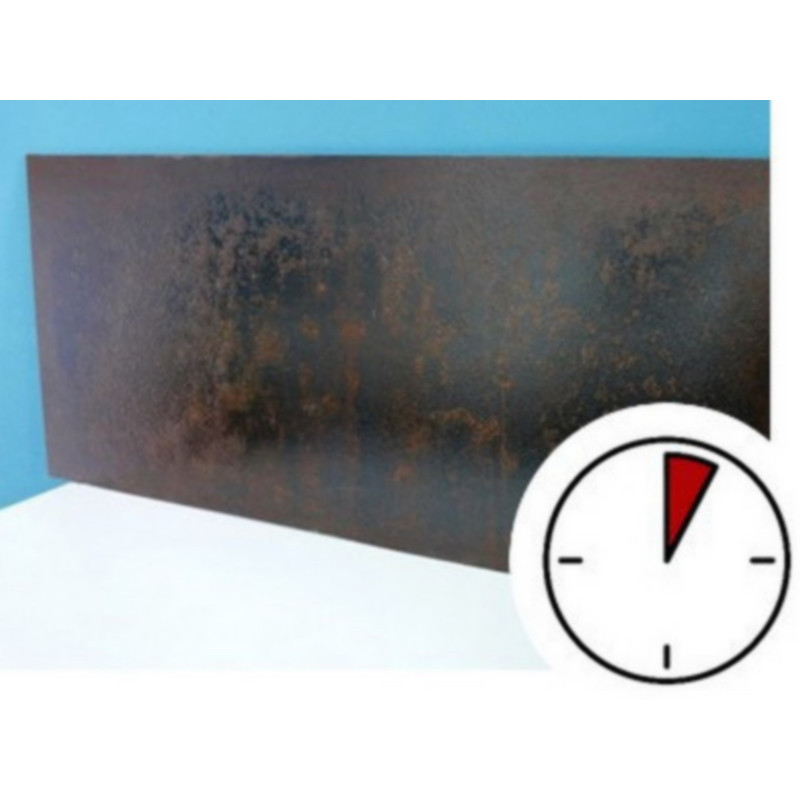

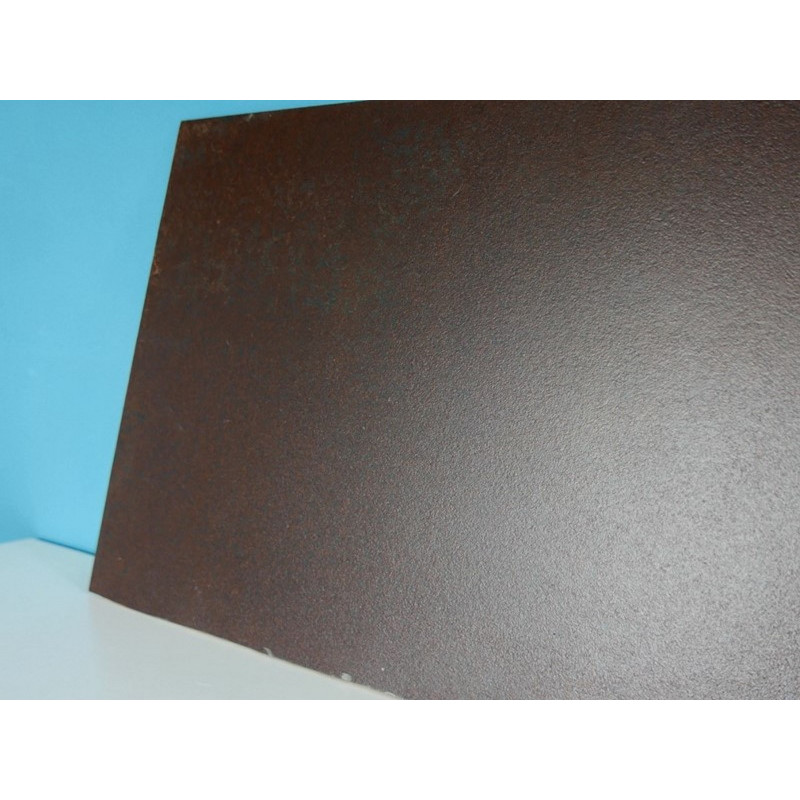

Monoguard Clear anti-corrosive varnish provides long-lasting protection against corrosion and external conditions. The varnish does not crack, peel or yellow. It allows you to preserve the effect of raw or rusted metal. It is ideal for both small jobs and large architectural projects.

Monoguard Clear anti-corrosive varnish - key properties:

- long-lasting corrosion protection in C4, C3, and C2 environments

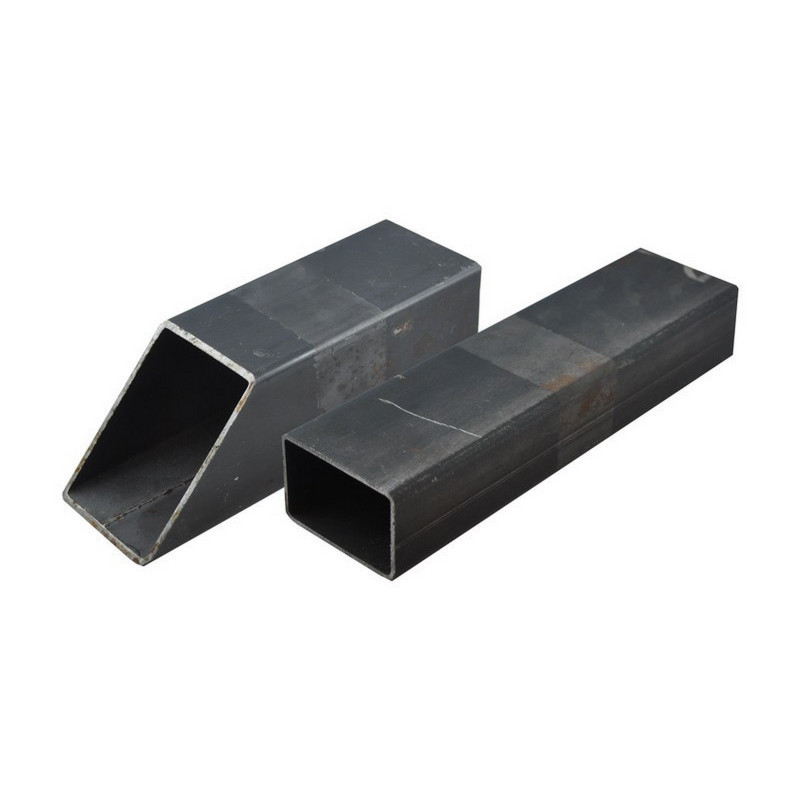

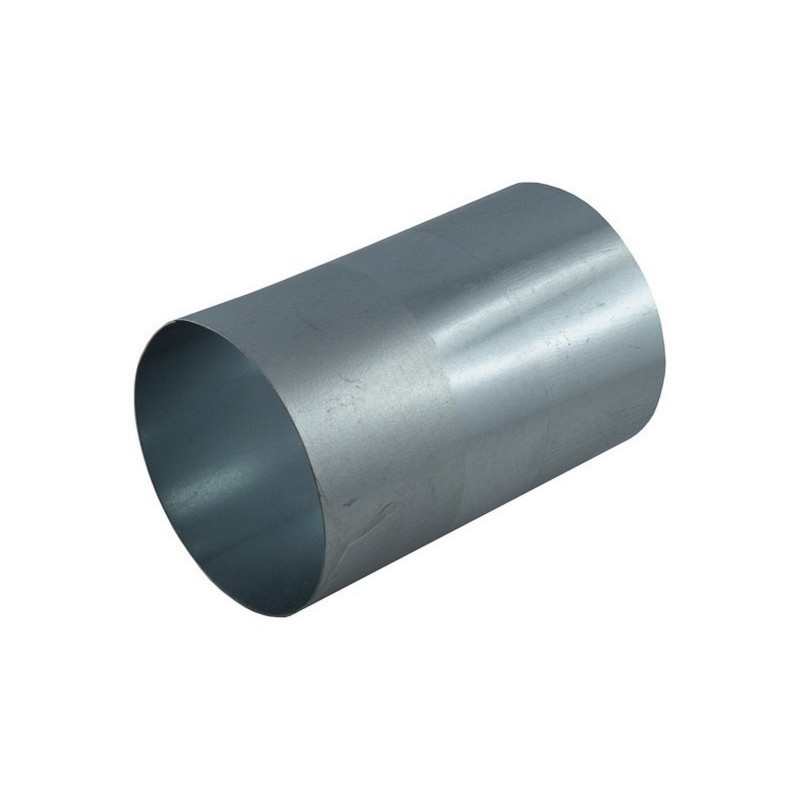

- excellent adhesion to many ferrous and non-ferrous metals, including: steel*, cast iron*, zinc, aluminum**, copper**, etc. (** appropriate substrate preparation may be required - more information)

- very good protection against outdoor conditions, UV rays, temperature changes

- good flexibility

- does not yellow, peel or crack

- water-soluble - low VOC content

- based on a new generation of acrylic resins and special anti-corrosion substances

- dries very quickly - touch dry in 2 hours; recoatable in 4 hours

- available in 3 finishes: semi-gloss, satin, matte

Monoguard Clear is available in three finishes:

- Semi-gloss +/- 70% +/- 5

- Satin: +/- 35% +/- 5

- Matte: +/- 10% +/- 5

Coverage:

- roller/brush application - 6-8 m²/l per coat

- spray application - 5 m²/l per coat

More information about Monoguard Clear anti-corrosive varnish.

Application:

Thanks to the above properties, Monoguard Clear anti-corrosion varnish is ideal for protecting, among others:

- metal structures: flyovers, pipelines, towers, supports

- external cladding: silos, tanks in production plants, refineries

- small metal elements: railings, fences, barriers, racks, doors

- equipment: construction cranes, tankers, trailers, salt spreaders, containers, etc.

Adhesion of Monoguard Clear to ferrous and non-ferrous metals:

Adhesion to ferrous metals:

Monoguard Clear anti-corrosion varnish has excellent adhesion to ferrous metals—steel and cast iron—similar to Monoguard anti-corrosion paint.

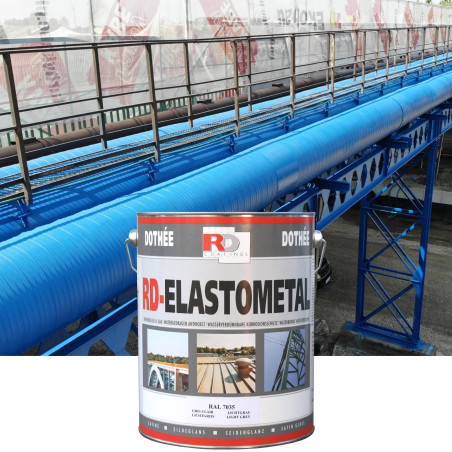

The adhesion of Monoguard Clear increases over time. Weeks and months after application, the innovative ingredients inside the coating continue to increase the bond, reaching levels of up to 17 MPa / 2500 PSI when performing a pull-off test in accordance with ISO 4624 (substrate adhesion test). These values significantly exceed the 7 MPa / 1000 psi regularly required by many industry specifications.

The excellent adhesion of Monoguard Clear also actively contributes to the protection of steel against corrosion. Because the coating adheres so well to the surface, it is more difficult for rust to begin its damaging expansion. The bond works so well that rust simply does not have enough strength to push the coating away and come into contact with the bare metal surface to which Monoguard Clear has literally bonded itself.

This is also a big advantage in the event of local damage to the coating, as rust will not be able to spread easily.

Steel plates 3.9, 3.11, and 3.12 protected with Monoguard anti-corrosion paint after 1,440 hours of testing in neutral salt spray

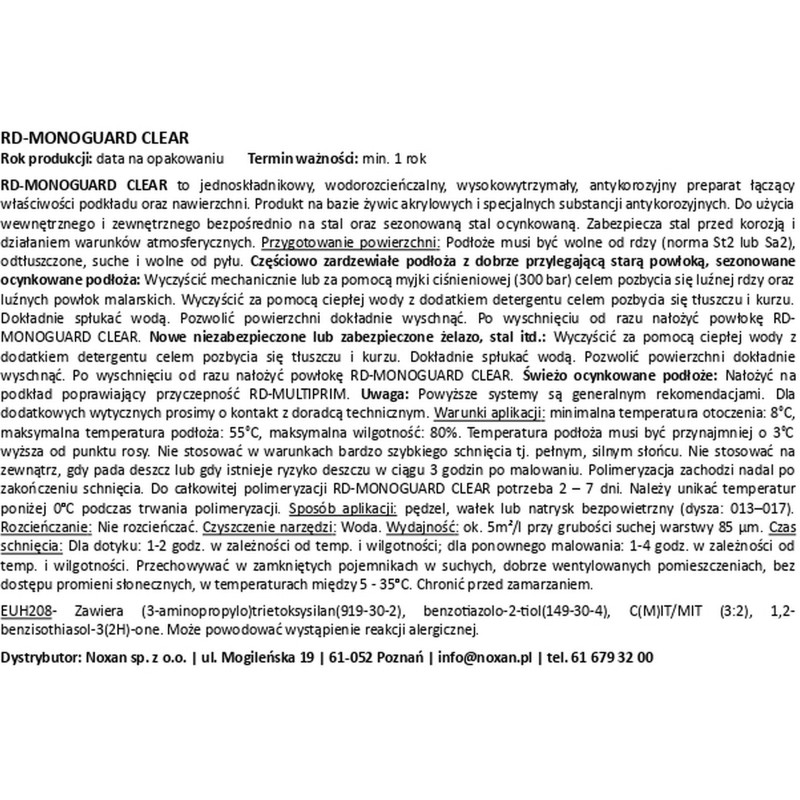

* Note on the application of Monoguard Clear varnish to clean black steel and cast iron:

The following note applies only to application on non-corroded ferrous metals (steel, cast iron). It does not apply to application on non-ferrous metals (aluminum, copper, zinc, stainless steel, etc.).

Monoguard Clear varnish is a water-based product. When applied to non-corroded cast iron and steel, the water evaporating from the varnish may activate rust. This means that small rust spots will appear immediately after painting. To reduce this risk, do not apply the varnish in high humidity conditions. Steel should also not be sandblasted before applying the varnish. Sandblasting activates the steel and increases the risk of rust spots after applying water-based varnish. In addition, we recommend using RD-Eco PowerClean to clean steel, which, thanks to additives that prevent rust formation, reduces the formation of small rust spots after cleaning the steel and during varnish application.

If you want to achieve a rust-free effect on ferrous metals, we always recommend testing the paint on a smaller element to confirm that the painting technique allows this.

** Adhesion to non-ferrous metals:

For non-ferrous metals, Monoguard Clear anti-corrosion paint has excellent adhesion to galvanized steel and stainless steel. For other metals, such as copper or aluminum, special substrate preparation may be required for best adhesion.

Detailed information is provided in the tables below.

Key:

- GT is the result of testing using the Cross Cut method;

- The best adhesion is GT0. The following numbers (1, 2, 3) indicate poorer adhesion (the higher the number, the poorer the adhesion);

- For more information, see here.

| GALVANIZED STEEL | ||

|---|---|---|

| Product | Substrate preparation | Adhesion |

| Monoguard Clear | water + detergent | GT0 |

| Conclusion: Monoguard Clear exhibits excellent adhesion on galvanized steel. No acid substrate preparation is required. | ||

| STAINLESS STEEL | ||

|---|---|---|

| Product | Substrate preparation | Adhesion |

| Monoguard Clear | water + detergent | GT0 |

| Conclusion: Monoguard Clear exhibits excellent adhesion on stainless steel. No acidic substrate preparation is required. | ||

| ALUMINUM | ||

|---|---|---|

| Product | Substrate preparation | Adhesion |

| Monoguard Clear | water + detergent | poor (adhesion is poor if we only clean and wash the substrate) |

| diluted sulfuric acid + rinse with water | GT1 | |

| Conclusion: In the case of aluminum, acidic preparation of the substrate is required to achieve adequate adhesion. We recommend testing on a smaller area to confirm good adhesion. | ||

| COPPER | ||

|---|---|---|

| Product | Substrate preparation | Adhesion |

| Monoguard Clear | water + detergent | GT2 |

| 10% hydrochloric acid + rinse with water | GT0 | |

| Conclusion: For copper, acidic preparation of the substrate is useful and recommended for best adhesion. During testing, cleaning with a 10% acid solution did not change the appearance of the copper. However, we obviously recommend carrying out a test cleaning on a smaller area to confirm that the aesthetic effect will be satisfactory. |

||

Instructional video:

Colorless anti-corrosion protection

Documentation:

Datasheets

- Technical data sheet - detailed product properties and application method

- Safety data sheet - chemical, health and safety, and transport information