Paint over rust - professional protection against corrosion

Elastometal - professional rust proofing paint

The unique formula of Elastometal rust proofing paint (high-quality anticorrosive pigments and a flexible, airtight coating) allow to permanently stop development of corrosion - also in cases of applying directly to rusty substrates. Thick (350 micrometers), highly elastic (above 200%), watertight coat of paint limits the access of air and moisture and thus stops the development of corrosion. Elastometal paint does not require sanding of a substrate before applying. It's an ideal solution in case of renovation and protection of steel constructions.

Anti corrosion coating - Elastometal is a single-component, water-borne, low VOC product - easy to apply. Rust proofingElastometal paint is based on styrene-acrylic copolymer and zinc phosphate. It's a highly durable, thick, permanently elastic system, suitable for use on heavily corroded steel exposed to harsh industrial and marine conditions (up to C5i / C5m).

Anti corrosion coating - Elastometal can be used as a surface coat or as a primer. Product requires minimal substrate preparation (St2 or Sa2). Rust proofing paint has an excellent adhesion to most substrates. Elastometal can be applied directly to rust, pure steel and iron, seasoned galvanized steel (minimum 1 year), old patinated, oxidized copper, or old paint coatings. Rust proofing Elastometal paint with Multiprim as a primer can be applied to new galvanized steel, stainless steel, zinc, aluminum, new copper, lead and other smooth substrates. Anti corrosion coating - Elastometal is resistant to UV rays, does not yellow over time, does not chalk and is resistant to changing weather conditions and changes of temperature - paint does not crack or flake off.

Anti corrosion coating for rusted and galvanized steel = revolution in the renovation of metal

We present the basic features of Elastometal anti corrosion coating distinguishing it from other anti corrosive paints. The following properties make Elastometal an excellent renovation system, both for protecting rusty steel constructions and for the renovation and sealing of metal roofs.

- excellent adhesion and high-quality anti-corrosion pigments - coating can be applied directly to corroded or clean steel, iron, seasoned galvanized steel, old patinated, oxidized copper, old paint coatings. In case of freshly galvanized steel, aluminum, stainless steel, new copper, lead and other smooth substrates, we recommend using Multiprim as a primer.

- sealing properties - 350 micrometers of Elastometal paint creates a coating which is impermeable to water and air. This stops the development of rust.

- minimal surface preparation - Rust proofing Elastometal paint can be applied directly to cleaned rusty substrates or well-adhered old paint coatings. It does not require sanding, which significantly reduces the cost and time needed to finish work.

- permanent flexibility (>200%) - Elastometal's flexibility prevents cracking and peeling of coating. That is why Elastometal is the perfect solution for places where shrinkage and relaxation of metal surfaces occur (due to thermal of elastic interactions). The high flexibility of the coating also provides protection against mechanical damage.

- high thixotropy - Elastometal does not bleed, can be applied in thick layers and ensure excellent edge coverage.

- dry fall of overspray - when applying with hydrodynamic drive, working on high constructions, with good drying conditions, excessive spatter of Elastometal turns into dry dust before it touches the ground. This helps to reduce the risk of painting surrounding objects and makes cleaning easier after finishing work.

- a long life of coating - proven in tests (CoRI) durability comparable with zinc, epoxy and polyurethane systems applied on non-rusted steel. There is a possibility of obtaining a 10-year warranty for anti-corrosion protection*.

- very high resistance to weather conditions - UV rays, salt water and most of the chemicals in the atmosphere.

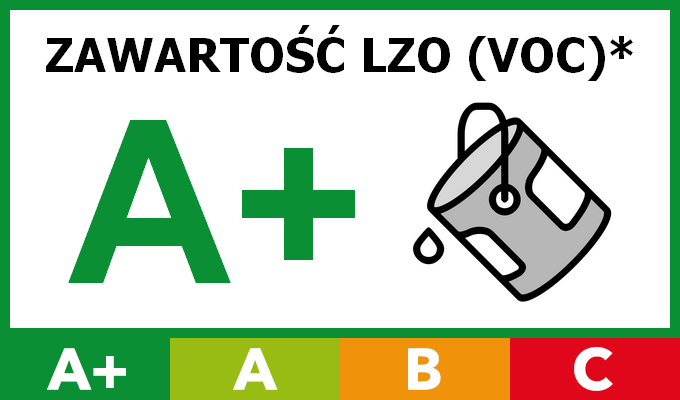

- eco-friendly - Paint for painting over rust is waterborne, has a low VOC content (8 g / l). In addition, Elastometal is non-flammable during and after application.

- suitable for use in food industry - as an anti corrosion coating for steel structures, claddings, elements inside and outside of industrial buildings (no direct food contact) - PZH hygenic certificate.

Salt Spray Test (1440 h) - Elastometal rust proofing paint resistance do development of corrosion

Applying 350 micrometers of Elastometal rust proofing paint on steel (also rusted), we obtain one of the most durable anti corrosive protection. The expected system durability is 15 - 25 years.

The durability of paint over rust Elastometal is comparable with epoxy, polyurethane or galvanizing systems. However, the application is much easier and cheaper than the mentioned systems. In the case of applying on a rusty substrate, the prior sanding is not required. It is enough to clean the surface to St2 or Sa2, preferably with a pressure washer (see FAQ).

Salt Spray Test - 1440 h - Elastometal

350 μm coating

After 1440 hours of Salt Spray Test, Elastometal anti corrosion coating remains intact. Even in the area of incisions, rust does not develop under the coating.

Paint over rust price:

-

- 25 kg - 1180,80 zł brutto / 960,00 zł netto

- 5 kg - 269,00 zł brutto / 218,70 zł netto

- 1 kg - 59,00 zł brutto / 47,98 zł netto

- buy online contact us

Coverage:

- application by roller/brush - 250 g/m2 per layer

- application by hydrodynamic drive - 400 g/m2 per layer

Colors:

Elastometal colors

Standard RAL colors

Custom colors

Corrosion protection systems with an expected time of protection of 15 - 25 years - long period (H)

Rust proofing Elastometal is an excellent system for the renovation of corroded steel. The possibility of applying directly to rust, without sanding, greatly reduces the costs of surface preparation. However, for protection to last for years - apply the coating in an appropriate thickness. In the case of systems with 350+ μm thickness of the coating, there is a possibility to obtain a 10-year warranty for anti-corrosive protection*.

| Environment: | System: | Cost: | Example: |

|

up to C3: urban, light indrustrial |

dry coating: 220+ μm 2 x 250 g/m2 Elastometal |

from 18,50 zł net per m2 |

|

|

up to C4: industrial |

dry coating: 260+ μm 2 x 300 g/m2 Elastometal |

from 22,00 zł net per m2 |

|

|

up to C5i; C5m: aggressive industrial maryne |

dry coating: 350+ μm 2 x 400 g/m2 Elastometal |

from 29,50 zł net per m2 |

|

Application of Elastometal on diverse substrates:

Anti corrosion coating - Elastometal has very good adhesion to many substrates. It can be applied directly on:

steel and iron

corroded steel

seasoned, galvanized steel

(min. 1 year)

old paint coatings

coated sheets, plastiol, polyester

aluminum - Elastometal dilluted 25% with water

old patinated, oxidized copper

For other substrates, we recommend using a suitable primer:

Rust preventing paint Monoguard, in the case of application on:

new or corroded stainless steel

Multiprim primer, in the case of application on:

new galvanized steel (< 1 year)

aluminum

new copper

new stainless steel

lead

PVC, polyvinylidene fluoride (PVDF) and other smooth substrates

Data sheets, reports, certificates, tests

Data sheets:

Elastometal has been tested by many authorized laboratories and other certifying institutions. The rust proofing paint has obtained a number of approvals and authorizations, including:

- CoRI test report - Coatings Research Institute - Limelette - Belgia ES-020611.b / 14.06.2002 - anti-corrosive properties, chemical resistance, temperature etc.

- Commercial Testing Company test report - Dalton - USA nr 04-12152 / 13.12.2004 - non-flammable

- Gent University test report – Belgium nr 6987 / 11.09.2002 – suitable for use in food industry

- PZH hygenic certificate – suitable for use in food industry as an anti corrosion coating for steel structures, claddings, elements inside and outside of industrial buildings (no direct food contact)

References - selected anti-corrosive works (1000 m2+)

We present an exemplary reference list of structures protected with Elastometal anticorrosion paint.

Full reference list for download is here.

| Poland | ||||

|---|---|---|---|---|

| Place | Protection | Area [m2] | Product | Data |

| Bukowice, Brzeg Dolny - Poland | Steel roofs - anti-corrosion + sealing | 5 900 | Elastometal | 2023 - 2024 |

| Łódź - Poland | Steel roofs - anti-corrosion + sealing | 2 810 | Elastometal | 2023 - 2024 |

| Poland | Steel roofs - anti-corrosion + sealing | 3 000 | Elastometal | 2023 - 2024 |

| Kąty Wrocławskie - Poland | Steel construction | 800 | Elastometal | 2024 |

| Gdańsk - Poland | Steel roofs - anti-corrosion + sealing | 5 000 | Elastometal | 2023 |

| Nowy Sącz - Poland | Steel roofs - anti-corrosion + sealing | 1 250 | Elastometal | 2023 |

| Środa Wielkopolska - Poland | Silos | 1 050 | Elastometal | 2023 |

| Gdańsk - Poland | Sheet pile walls | 750 | Elastometal | 2023 |

| Katowice - Poland | Steel roofs - anti-corrosion + sealing | 10 500 | Elastometal | 2021 - 2022 |

| Czechowice-Dziedzice - Poland | Pipelines - anti-corrosion | 4 000 | Elastometal | 2021 - 2022 |

| Chełmek - Poland | Pipelines - anti-corrosion | 2 000 | Elastometal | 2021 - 2022 |

| Chorzów - Poland | Steel roofs - anti-corrosion + sealing | 1 400 | Elastometal | 2022 |

| Suchy Las - Poland | Steel roofs - anti-corrosion + sealing | 1 350 | Elastometal | 2022 |

| Czempiń - Poland | Steel roofs - anti-corrosion + sealing | 3 500 | Elastometal | 2021 |

| Wrocław - Poland | Metal roofs - sealing | 2 600 | Elastometal | 2021 |

| Dobczyce - Poland | Steel roofs - anti-corrosion + sealing | 6 300 | Elastometal | 2020 - 2021 |

| Jaworzno - Poland | Steel constructions | 2 000 | Elastometal | 2020 |

| Wasilków - Poland | Steel roofs - anti-corrosion | 2 500 | Elastometal | 2020 |

| Mysłowice - Poland | Steel constructions | 2 400 | Elastometal | 2019 |

| Legnica - Poland | Steel roofs - anti-corrosion + sealing | 2 600 | Elastometal + fleece | 2018 |

| Bełchatów - Poland | Storage metal tanks | 830 | Elastometal + Metal Unicoat | 2018 |

| Bolechowo - Poland | Steel roofs - anti-corrosion + sealing | 2 500 | Elastometal + fleece | 2017 |

| Lubawka - Poland | Steel constructions | 2 200 | Elastometal | 2017-2019 |

| Słupsk - Poland | Metal cladding | 2 700 | Elastometal + Metal Unicoat | 2017 |

| Warszawa - Poland | Shipping containers | 2 000 | Elastometal + Metal Unicoat | 2016 |

| Ozimek - Poland | Sheet pile walls | 4 500 | Elastometal | 2016 |

| Warszawa - Poland | Shipping containers | 2 000 | Elastometal + Metal Unicoat | 2016 |

| Krosno - Poland | Steel roofs - anti-corrosion | 4 200 | Elastometal + Metal Unicoat | 2016 |

| Mikołajów - Poland | Steel constructions | 2 000 | Elastometal | 2015 |

| Piaseczno - Poland | Steel roofs - anti-corrosion + sealing | 3 400 | Elastometal | 2015 |

| Poznań - Poland | Steel roofs - anti-corrosion + sealing | 3 800 | Elastometal | 2015 |

| Starachowice - Poland | Steel roofs - anti-corrosion | 1 000 | Elastometal | 2015 |

| Warszawa - Poland | Steel roofs - anti-corrosion + sealing | 1 400 | Elastometal + fleece | 2014 |

| Rzeszów - Poland | Steel roofs - anti-corrosion + sealing | 2 500 | Elastometal + fleece | 2013 |

| Nowy Tomyśl - Poland | Steel roofs - anti-corrosion | 2 000 | Elastometal | 2011 |

| World | |||||

|---|---|---|---|---|---|

| Investor | Place | Protection | Area [m2] | Product | Data |

| Halatra - Houthalen | Helchteren - Belgium | Metal cladding | 3 000 | Elastometal + Metal Unicoat | 2007 |

| Carlsberg | Denmark | Steel bridge | 3 500 | Elastometal | 2006 |

| Mitsubishi Material LTD | Gifu Prefecture - Japan | Steel masts | 3 400 | Elastometal | 2005 |

| Stadion Yankee | Nowy Jork - USA | Steel roofs | 7 000 | Elastometal | 2005 |

| Canon LTD | Ibaraki - Japan | Metal walls / roofs | 5 400 | Elastometal | 2004 |

The use of Elastometal - paint over rust

Covering all common metal surfaces - Elastometal has very good adhesion and can be applied to various surfaces, such as:

- iron, steel, seasoned steel (CorTen),

- rusted steel cleaned by hand or pressure washer (St2 / Sa2),

- old patinated, oxidized copper,

- old, well-adhered paint coatings,

- seasoned for min. 1 year galvanized steel (on new galvanized steel, aluminum, stainless steel, new copper, lead and other smooth substrates use Multiprim as a primer)

Anti corrosion coating in a diverse environment - Elastometal is an ideal solution for the renovation of diversified rusty elements. The unique properties of the paint make it a very good solution in case of anti corrosive protection of the following elements:

Due to the application directly on rust, resistance to external conditions and minimal preparation of the substrate:

steel constructions, flyovers, pipelines, towers, supports, refineries, petrochemical and chemical plants

rusty bridges, sea constructions

Due to the durable elasticity and sealing properties:

corroded metal roofs

metal roofs that require sealing

Due to the excellent adhesion and excellent anti-corrosion properties:

metal on buildings (metal cladding, walls made of coated sheets

Due to the permanent flexibility (> 200%) and high thixotropy (does not bleed):

elements made of corten steel

external coating for water, oil, gas, grain tanks etc.

Due to the impact resistance and a thick, elastic, rubber-like coating:

high voltage poles

equipment - chassis, frames, construction cranes, etc.

Elastometal as an anti-corrosion and sealing coating

Elastometal remains very elastic after drying. This particular feature allows the coating to follow deformations of the metal substrate due to temperature changes, also in the area of plate joins. As a result, Elastometal applied together with a reinforcing mesh creates a watertight, highly elastic (>200%), durable (15 - 25 years), seamless membrane. All information on sealing metal roofs can be found on the following page.

Limitations in the application of Elastometal

Resistance to abrasion

Elastometal can be used on floors exposed to pedestrian traffic. However, during such works, the coating should be finished with Monovar PU varnish or RD-Aquatop PU topcoat for better washability. In the picture: Elastometal mixed with quartz sand can create an anti-slip coating on stairways made of corrugated metal. System: 2 x 250g Elastometal + quartz sand + 250g Elastometal + 2 x RD-Aquatop PU

In the case of floors exposed to the movement of vehicles (in particular the forklifts), the resistance to abrasion of Elastometal may not be sufficient. We suggest using epoxy systems for forklifts.

Chemical resistance

Elastometal has improved chemical resistance and is an appropriate system for use on walls exposed to different vapors and fumes (see tests; CoRI report). For works where even higher chemical resistance is required, it is possible to secure the coating with an additional layer of Hydrograff HP polyurethane varnish. If you have any questions, please contact us.

Elastometal can be used for elements that are often flooded with water. However, Elastometal should not be used for elements that are constantly submerged, e.q inside of water tanks. In these conditions, Elastometal can soften up. For these types of application, we recommend epoxy primer + polyurethane topcoat.

Aesthetics and washability

Elastometal forms a slightly viscous coating, which can get dirty. In the case of flat roofs painted in shades of gray this is not a key problem. If the aesthetic effect on a given roof is very important, Elastometal can be additionally finished with Hydrograff HP polyurethane varnish. In the case of roofs with a slope of at least 30 degrees, we suggest finishing with Metal Unicoat paint.

Elastometal leaves streaks when applying with a brush. That is why it is not a suitable product for small works such as painting fences or gates. For such works, we recommend using Monoguard paint.

If a perfectly smooth coating is required, apply Elastometal using a hydrodynamic drive.

For more information, see FAQ.

Notes on the application:

Tools:

-

Application with a roller or brush -

Elastometal is a very thick paint and creates a texture when applied with a roller or brush.

For more information, see FAQ.

- Application with hydrodynamic drive - allows to obtain an aesthetic finish and fast application of anti-corrosion coating.

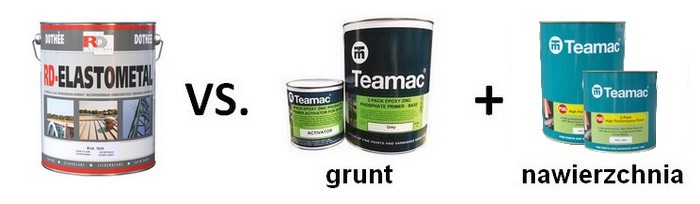

Elastometal vs. epoxy-polyurethane systems

Durability and anti-corrosive properties of Elastometal are comparable with epoxy, polyurethane or zinc coating systems. However, the application is much easier and cheaper.

Application time - application in 1-2 days

| Elastometal: | Epoxy / polyurethane systems: |

| 2 layers system | 3 layers system |

| directly on rust | sanding required |

Ease of application

| Elastometal: | Epoxy / polyurethane systems: |

| primer and topcoat in one | primer, interlayer, topcoat |

| single component = no paint loss | required mixing of component A and B |

Rust proofing paint - Elastometal

Contents of Volatile Organic Compounds (VOC) - 8 g/l

Emission levels from A+ (very low) to C (high).

Additional information on Volatile Organic Compounds.

Low-emissive materials for buildings subjected to LEED certification

The product meets LEED v4 requirements for volatile organic compounds content.

Frequently asked questions about rust proofing paint - Elastometal:

How to prepare a rusty steel for painting?

Prepare the substrate to St2 or Sa2. There must be no oil, grease, dust, poorly adhered rust, loose paint and other impurities on the surface. The substrate can be prepared using hand tools (scraping, brushing, grinding) and then degreased and rinsed with water. However, the most effective method is washing the substrate with a pressure washer with a rotary nozzle under pressure of min. 300 bar. This method makes it possible to remove loose rust and loose paint coatings. It leaves the substrate clean, stable and ready for painting.

We show this technique on the renovated metal roof, metal cladding and crane to show its effectiveness. The substrate must dry well before applying the paint.

Application of anti corrosion coating - Elastometal with a brush

Elastometal due to its high density leaves a slightly uneven surface (traces of brush) when applied with brush or roller. The effect is invisible from several meters. If a smooth coating is required, apply Elastometal with a hydrodynamic drive or replace the product with Monoguard paint.

Elastometal applied with a brush.

Characteristics of Elastometal

| System | Elastometal |

|---|---|

| Drying time: | |

| - to touch: | 3 h |

| - for recoating: | po 6 h |

| Temperature resistance: | 80oC (temporary 90oC) |

| VOC content: | max 8 g/l |

| Theoretical consumption: |

250 - 400 g/m2

on coat depending on the application method

(400 g/m2 at the layer with a thickness 180 µm) |

| Finish: | Satin |

| Purchase: |

contact us buy online |

* 10-year warranty for anti-corrosion protection is issued by the paint manufacturer RD-Coatings and a company that performs painting work. In order to obtain a warranty, work must be controlled by RD-Coatings. Work must be carried out by an approved contractor in accordance with the 10-year RD-Coatings procedures.

Check also:

Bezspoinowe pokrycia dachowe

Elastodeck

Farba elewacyjna wodoszczelna

Elastoflex

Farba i podkład do aluminium 2w1

Multiprim

Farba i podkład na ocynk 2w1

Monoguard

If you are interested in proffesional paint against corrosion - Elastometal please contact us info@noxan.pl

kup online

kup online

skontaktuj się z nami

skontaktuj się z nami